LINE THERMAL PRINTER

MODEL CT-S4500

User’s Manual

WEEE MARK

|

If you want to dispose of this product, do not mix it with general household waste.

There is a separate collection systems for used electronics products in accordance

with legislation under the WEEE Directive and is effective only within European Union.

|

|

Wenn Sie dieses Produkt entsorgen wollen, dann tun Sie dies bitte nicht zusammen mit

dem Haushaltsmüll. Es gibt im Rahmen der WEEE-Direktive innerhalb der Europäischen

Union gesetzliche Bestimmungen für separate Sammelsysteme für gebrauchte elektronische

Geräte und Produkte.

|

|

Si vous souhaitez vous débarrasser de cet appareil, ne le mettez pas à la poubelle

avec vos ordures ménagères. Il existe un système de récupération distinct pour les

vieux appareils électroniques conformément à la législation WEEE sur le recyclage

des déchets des équipements électriques et électroniques qui est uniquement valable

dans les pays de l’Union européenne.

Les appareils et les machines électriques et électroniques contiennent souvent des

matières dangereuses pour l’homme et l’environnement si vous les utilisez et vous

vous en débarrassez de façon inappropriée.

|

|

Si desea deshacerse de este producto, no lo mezcle con residuos domésticos de carácter

general. Existe un sistema de recogida selectiva de aparatos electrónicos usados,

según establece la legislación prevista por la sobre residuos de aparatos eléctricos

y electrónicos (RAEE), vigente únicamente en la Unión Europea.

|

|

Se desiderate gettare via questo prodotto, non mescolatelo ai rifiuti generici di

casa. Esiste un sistema di raccolta separato per i prodotti elettronici usati in conformità

alla legislazione RAEE, valida solo all’interno dell’Unione Europea.

|

|

Deponeer dit product niet bij het gewone huishoudelijk afval wanneer u het wilt verwijderen.

Er bestaat ingevolge de WEEE-richtlijn een speciaal wettelijk voorgeschreven verzamelsysteem

voor gebruikte elektronische producten, welk alleen geldt binnen de Europese Unie.

|

|

Hvis du vil skille dig af med dette produkt, må du ikke smide det ud sammen med dit

almindelige husholdningsaffald. Der findes et separat indsamlingssystem for udtjente

elektroniske produkter i overensstemmelse med lovgivningen under WEEE-direktivet,

som kun er gældende i den Europæiske Union.

|

|

Se quiser deitar fora este produto, não o misture com o lixo comum. De acordo com

a legislação que decorre da Directiva REEE – Resíduos de Equipamentos Eléctricos e

Electrónicos, existe um sistema de recolha separado para os equipamentos electrónicos

fora de uso, em vigor apenas na União Europeia.

|

|

Jeżeli zamierzasz pozbyć się tego produktu, nie wyrzucaj go razem ze zwykłymi domowymi

odpadkami. Według dyrektywy WEEE obowiązującej w Unii Europejskiej dla używanych produktów

elektronicznych należy stosować oddzielne sposoby utylizacji.

|

Compliance Statement for European Users

|

IMPORTANT: This equipment generates, uses, and can radiate radio frequencyenergy and if not

installed and used in accordance with the instruction manual, maycause interference

to radio communications. It has been tested and found to complywith the limits for

a Class A computing device pursuant to Subpart J of Part 15 of FCCRules, which are

designed to provide reasonable protection against such interferencewhen operated in

a commercial environment. Operation of this equipment in aresidential area is likely

to cause interference, in which case the user at his ownexpense will be required to

take whatever measures may be necessary to correct theinterference.

CAUTION: Use shielded cable for this equipment.

|

|

Sicherheitshinweis

Die Steckdose zum Anschluß dieses Druckers muß nahe dem Gerät angebracht und leicht

zugänglich sein.

|

|

For Uses in Canada

This Class A Information Technology Equipment (ITE) complies with Canadian CAN ICES-3(A)/NMB-3(A).

This Information Technology Equipment (ITE) does not exceed the Class A limits for

radio noise emissions from digital apparatus set out in the Radio Interference Regulations

of the Canadian Department of Communications.

Pour L’utilisateurs Canadiens

Cet Equipements informatiques (EI) de la classe A est conforme a la norme CAN ICES-3(A)/NMB-3(A)

du Canada.

Le present Equipements informatiques (EI) n’emet pas de bruite radio electriques depassant

les limites applicables aux appareils numeriques de la classe A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le ministere des Communications

du Canada.

|

GENERAL PRECAUTIONS

- Before using this product, be sure to read through this manual. After having read

this manual, keep it in a safe, readily accessible place for future reference.

- The information contained herein is subject to change without prior notice.

- Reproduction or transfer of part or all of this document in any means is prohibited

without permission from Citizen Systems.

- Note that Citizen Systems is not responsible for any operation results regardless

of omissions, errors, or misprints in this manual.

- Note that Citizen Systems is not responsible for any trouble caused as a result of

using options or consumables that are not specified in this manual.

- Except explained elsewhere in this manual, do not attempt to service, disassemble,

or repair this product.

- Note that Citizen Systems is not responsible for any damage attributable to incorrect

operation/handling or improper operating environments that are not specified in this

manual.

- Data is basically for temporary use and not stored for an extended period of time

or permanently. Please note that Citizen Systems is not responsible for damage or

lost profit resulting from the loss of data caused by accidents, repairs, tests or

other occurrences.

- If you find omissions, errors, or have questions, please contact your Citizen Systems

dealer.

- If you find any pages missing or out of order, contact your Citizen Systems dealer

for a replacement.

|

Use of the Made for Apple badge means that an accessory has been designed to connect specifically to the Apple product(s) identified in the badge and has been certified by the developer to meet Apple performance standards. Apple is not responsible for the operation of this device or its compliance with safety and regulatory standards.

Please note that the use of this accessory with an Apple product may affect wireless performance.

- Apple, Apple TV, Apple Watch, iPad, iPad Air, iPad Pro, iPhone, and Lightning are trademarks of Apple Inc., registered in the U.S. and other countries. tvOS is a trademark of Apple Inc. The trademark “iPhone” is used in Japan with a license from Aiphone K.K.

- EPSON and ESC/POS are registered trademarks of Seiko Epson Corporation.

- QR Code is a registered trademark of DENSO WAVE INCORPORATED.

- Ethernet is a registered trademark of Fuji Xerox Corporation.

- Bluetooth® is a registered trademark of Bluetooth-SIG Inc.

- CITIZEN is a registered trademark of Citizen Watch Co., Ltd.

- All other trademarks are the property of their respective owners.

- Citizen Systems use these trademarks in accordance with the license of relevant owners.

Copyright© CITIZEN SYSTEMS JAPAN CO., LTD. 2019

PRECAUTIONS ON PRINTER INSTALLATION

WARNING

|

- Do not use or store this product in a place where it will be exposed to:

- Flames or moist air.

- Direct sunlight.

- Hot airflow or radiation from a heating device.

- Salty air or corrosive gases.

- Ill-ventilated atmosphere.

- Chemical reactions in a laboratory.

- Airborne oil, steel particles, or dust.

- Static electricity or strong magnetic fields.

- These locations create the risk of printer damage, as well as product failure, overheating,

emission of smoke, fire, or electric shock.

They can also result in fire or electric shocks and so should always be avoided.

|

|

- Do not drop any foreign object nor spill liquid into the printer. Do not place any

object on the printer either.

- Do not drop any metallic object such as paper clips, pins or screws into the printer.

- Do not place a flower vase, pot, or anything containing water on the printer.

- Do not spill coffee, soft drinks, or any other liquid into the printer.

- Do not spray insecticide or any other chemical liquid over the printer.

- Dropping a metallic foreign object into the printer, may cause printer failure, fire,

or electric shock.

Should it occur, immediately turn the printer off, unplug it from the supply outlet,

and call your local Citizen Systems dealer.

|

|

- Do not handle the printer in the following ways:

- Do not subject the printer to strong impacts or hard jolts (e.g., being stepped on,

dropped or struck).

- Never attempt to disassemble or modify the printer.

- These actions create the risk of printer damage, as well as product failure, overheating,

emission of smoke, fire, or electric shock.

They can also result in fire or electric shocks and so should always be avoided.

|

|

- This device is not appropriate to be used where a child may be present. Install, store,

or use the device where it cannot be reached by a child.

- Electric appliances could cause an unexpected injury or accident if they are handled

or used improperly.

- Keep the power cord and signal cables out of the reach of children. Also children

should not be allowed to gain access to any internal part of the printer.

- The plastic bag the printer came in must be disposed of properly or kept away from

children. Wearing it over the head may lead to suffocation.

|

|

PRECAUTIONS IN HANDLING THE PRINTER

WARNING

|

- Please observe the following precautions for power source and power cord:

- Do not plug or unplug the power cord with a wet hand.

- Use the printer only at the specified supply voltage and frequency.

- Use only the specified AC adapter with the printer.

- Use only the power cord that comes with the printer, and never use the supplied power

cord with another device.

- Check to make sure that the supply outlet from which the printer is powered has a

sufficient capacity.

- Do not supply the printer from a power strip or current tap shared with other appliances.

- Do not plug the power cord into an electric outlet with dust or debris left on the

plug.

- Do not use a deformed or damaged power cord.

- Do not move the printer while its power is on.

- Neglecting to handle it properly may result in printer failure, emission of smoke,

fire, or electric shock.

- An overload may cause the power cord to overheat, catch fire, or the circuit breaker

to trip.

- Do not allow anything to rest on the power cord. Do not place the printer where the

power cord may be stepped on.

- Do not subject the power cord to severe bending, twisting, or pulling. Do not carry

the product while it is in this state either.

- Do not attempt to modify the power cord unnecessarily.

- Do not place the power cord near any heating device.

- Neglecting these cautions may cause wires or insulation to break, which could result

in electric leakage, electric shock, or printer failure.

If the power cord sustains damage, contact your Citizen Systems dealer.

- Do not leave things around the electric outlet.

- Supply power to the printer from a convenient electric outlet, readily accessible

in an emergency.

- Pull the plug to immediately shut it down in an emergency.

- Insert the power plug fully into the outlet.

- If the printer will not be used for a long time, disconnect it from its electric outlet.

- Hold the plug and connector when plugging or unplugging the power cord or signal cable

after turning off the printer and the appliance connected to it.

|

|

GENERAL OUTLINE

This product is a line thermal printer capable of printing on media up to 4 inches

wide.

It can instantly print labels, tickets, and receipts containing a large volume of

data that would not fit on normal width receipt paper.

This printer has extensive features so it can be used in a wide range of applications.

EXPLANATION OF PRINTER PARTS

MAINTENANCE AND TROUBLESHOOTING

"Made for iPod," "Made for iPhone," and "Made for iPad" mean that an electronic accessory

has been designed to connect specifically to iPod, iPhone, or iPad, respectively,

and has been certified by the developer to meet Apple performance standards. Apple

is not responsible for the operation of this device or its compliance with safety

and regulatory standards.

Please note that the use of this accessory with iPod, iPhone or iPad may affect wireless

performance.

- iPad, iPhone and iPod touch are trademarks of Apple Inc., registered in the U.S. and

other countries. iPad Air and iPad mini are trademarks of Apple Inc.

- EPSON and ESC/POS are registered trademarks of Seiko Epson Corporation.

- QR Code is a registered trademark of DENSO WAVE INCORPORATED.

- Ethernet is a registered trademark of Fuji Xerox Corporation.

- Bluetooth® is a registered trademark of Bluetooth-SIG Inc.

- CITIZEN is a registered trademark of Citizen Watch Co., Ltd.

- All other trademarks are the property of their respective owners.

- Citizen Systems use these trademarks in accordance with the license of relevant owners.

Copyright© CITIZEN SYSTEMS JAPAN CO., LTD. 2019

Features

- High-speed printing at up to 200 mm/sec possible

- Stylish design

- Support for media up to 112 mm wide

- Support for label paper and black mark paper

- High-speed cutter employed

- USB interface included as standard

- Equipped with a standard USB power supply port

- Interchangeable interface board

- Built-in drawer kick interface

- USB-linked power OFF function available

- Paper saving function available

- ENERGY STAR compliant power saving function

- XML/Web print function included (wired LAN or wireless LAN model)

- USB host function capable of controlling peripheral devices included (wired LAN or

Bluetooth USB host model)

- Support for the JIS X0213 third and fourth level Kanji character sets

- Support for the simplified and traditional Chinese character sets and Hangul character

set

- Support for UTF-8 using commands

- Various customizations using the memory switches possible

- User created characters and logos can be saved in the user memory

- Support for barcodes and 2D codes, including GS1-DataBar

- Apple MFi certified Bluetooth communication support (Bluetooth model)

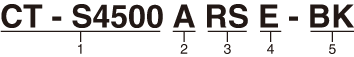

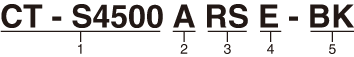

Model Classification

Model numbers indicate printer features according to the following system.

- 1.Model name

- 2.AC adapter storage case

- A: None

- S: Yes

- 3.Interface

- RS: Serial RS-232C+USB

- ET: Ethernet+USB

- HET: Ethernet (USB host function) + USB

- BT: Bluetooth+USB

- HBT: Bluetooth (USB host function) + USB

- WX: Wireless LAN+Ethernet+USB

- NN:USB

- 4.Market

- U: North America

- E: Europe

- I: India

- 5.Body case color

- WH: Pure white

- BK: Black

Contact us in advance for special combinations, some of which may not be available.

Basic Specifications

| Item |

Specifications |

| Model |

CT-S4500 |

| Print method |

Line thermal dot print method |

| Print widths |

104 mm/832 dots, 90 mm/720 dots, 82.5 mm/660 dots, 72 mm/576 dots, 68.25 mm/546 dots,

64 mm/512 dots, 54.5 mm/436 dots, 54 mm/432 dots, 52.5 mm/420 dots, 48 mm/384 dots,

45 mm/360 dots, factory default 104 mm/832 dots

|

| Dot density |

8 × 8 dots/mm (203 dpi) |

| Print Speed |

200 mm/sec (maximum speed, print density level 100%, 1600 dot lines/sec) |

| Number of print columns *1 |

Font |

Maximum number of characters (columns) / 112mm |

Maximum number of characters (columns) / 80mm |

Maximum number of characters (columns) / 58mm |

Dot configuration

(dots)

|

| Font A |

69 |

48 |

35 |

12 × 24 |

| Font B |

92 |

64 |

46 |

9 × 24 |

| Font C |

104 |

72 |

52 |

8 × 16 |

| Character size *2 |

Font A:1.50×3.00 mm, Font B:1.13×3.00 mm, Font C:1.00×2.00 mm |

| Character type |

Alphanumeric characters, international characters, PC437/737/850/852/857/858/860/862/863/864/865/866,

WPC1251/1252/1253/1255/1258, Katakana, ThaiCode 11/18 (1Pass/3Pass), TCVN-3, Kanji (JIS first,

second, third, and fourth level), Kana, extended characters, JIS X0213, GB18030, BIG5,

KS Hangul, EUC Hangul

|

| User memory |

384 KB (capable of storing user-defined characters and logos) |

| Bar code types |

UPC-A/E, JAN(EAN) 13 digits/8 digits, ITF, CODE39, CODE128, CODABAR (NW-7), CODE93,

PDF417, QR Code, GS1-DataBar

|

| Line spacing |

4.25 mm (1/6 inch) (Variable by command) |

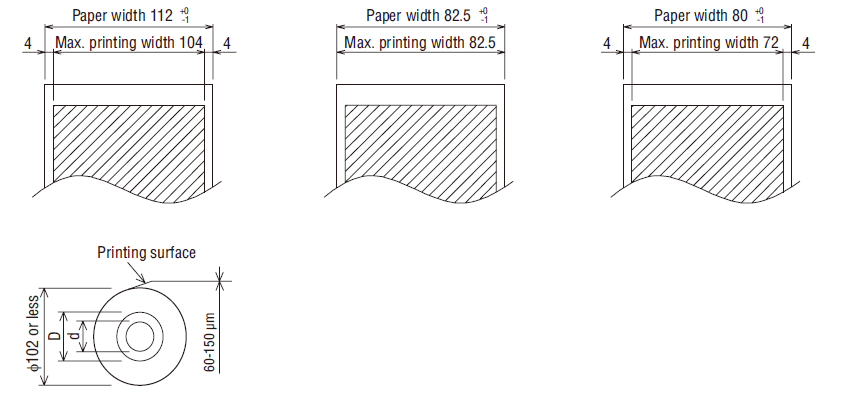

| Paper |

Roll paper: 112 mm × maximum Ø102 mm

Paper thickness: 60-85 μm (25.4 mm ≥ core tube inner diameter ≥ 12 mm/32 mm ≥ core

tube outer diameter ≥ 18 mm)

85-150 μm (core tube diameter: inner 25.4 mm / outer 32 mm)

Label paper: 150 μm or less (core tube diameter: inner 25.4 mm / outer 32 mm)

|

| Interface |

Serial (RS-232C standard), USB, Bluetooth+USB, LAN, wireless LAN+LAN, LAN (USB host

function) (USB 2 port)), Bluetooth (USB host function) (USB 2 port))

|

| Ethernet |

100BASE-TX/10BASE-T |

| Wireless LAN |

IEEE802.11n, IEEE802.11a, IEEE802.11g, IEEE802.11b |

| Bluetooth |

Version: Bluetooth 3.0 + EDR

Profile: SPP (Serial Port Protocol), iAP (iPod Accessory Protocol)

Power class: Class2

|

| USB power supply port |

Max. 2.1 A |

| Cash drawer kick-out |

Supports 2 cash drawers |

| Input buffer |

4 K bytes/45 bytes |

| Power consumption |

Approximately 65 W (for normal printing), approximately 1.5 W (during standby) |

| AC Adapter |

Rated input: AC 100 to 240 V, 50/60 Hz, 150 VA

Rated output: DC 24 V, 2.5 A

|

| Weight |

Standard model: Approximately 2.5 kg

Model with stored AC adapter: Approximately 3.2 kg

|

| Outside dimensions |

Standard model: 170 (W) × 151.3 (H) × 216.2 (D) mm

Model with stored AC adapter: 170 (W) × 193.3 (H) × 216.2 (D) mm

|

| Operating temperature and humidity |

5 to 40°C,

10 to 90% RH (no condensation) (60 μm ≤ paper thickness ≤ 85 μm)

10 to 80% RH (no condensation) (85 μm ≤ paper thickness ≤ 150 μm)

|

| Storage temperature and humidity |

-20 to 60°C, 10 to 85% RH (no condensation) |

| Print head life *3 |

Thermal roll paper: 100 km, 200 million pulses

Thermal label roll paper: 50 km, 100 million pulses

|

| Auto cutter life *3 |

Thermal roll paper: 1 million cuts

Thermal label roll paper: 200 thousand cuts

|

| Safety standard *4 |

UL, cUL, FCC, IC, CE, UKCA *5 |

Notes:

*1: The number of printable columns is selected using a memory switch.

The numbers of columns noted in this table refer to typical models. The number of

columns varies depending on specifications.

*2: Characters appear small because the dimensions include a blank area surrounding

each character.

*3: According to our test conditions

*4: This standard applies when our AC Adapter is used.

*5: Please contact us for information on other regions and the latest status such as standardnumbers.

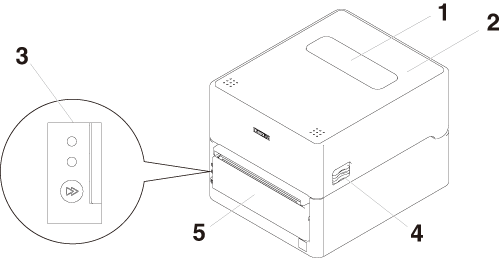

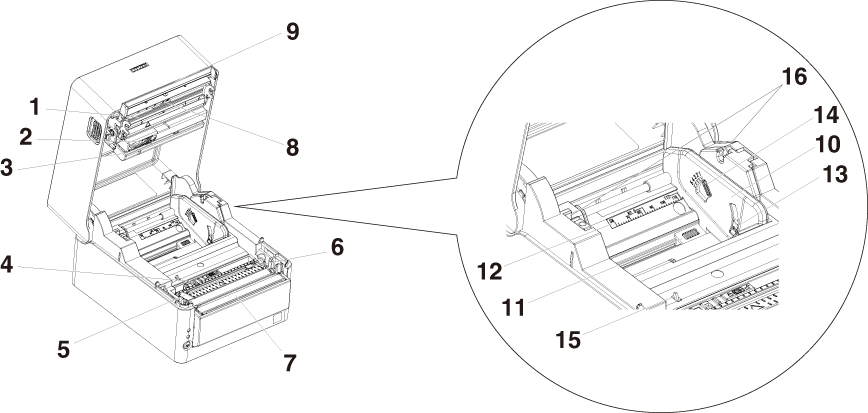

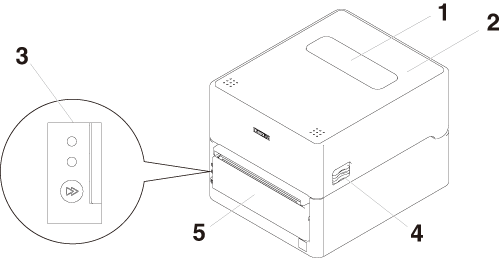

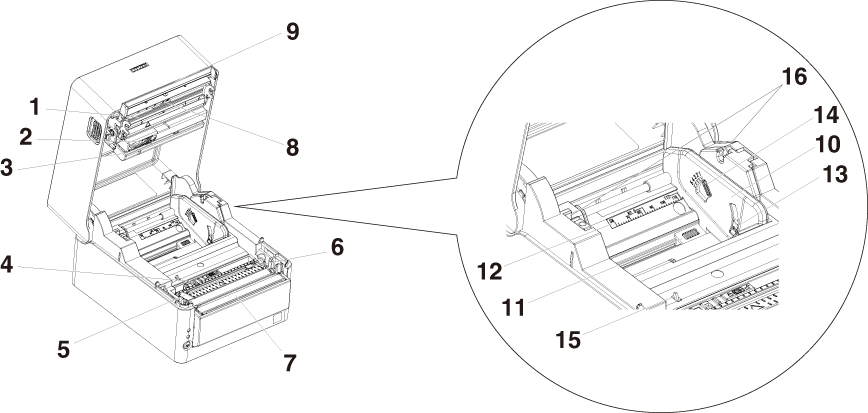

Printer Appearance

Names of parts

Standard model

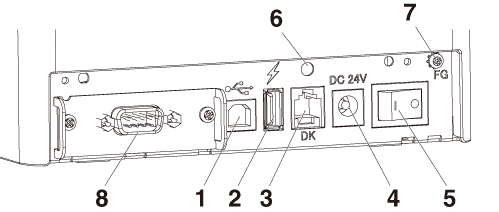

Model with stored AC adapter

- 1.Media window

- Enables users to check the media level.

- 2.Top cover

- Opens upward so users can replace or set media.

- 3.Operation panel

- 4.Cover release buttons

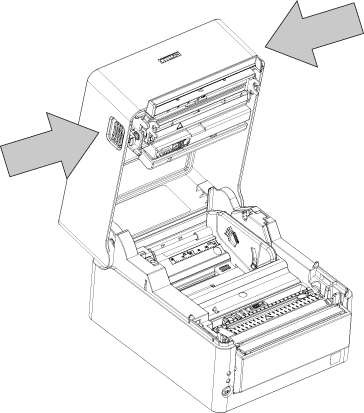

- The cover is opened by pressing the buttons on both the right and left sides.

- 5.Auto cutter

- 6.AC adapter storage case

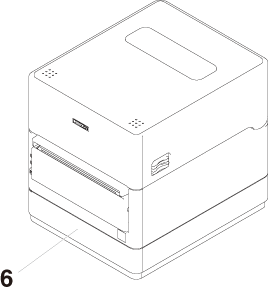

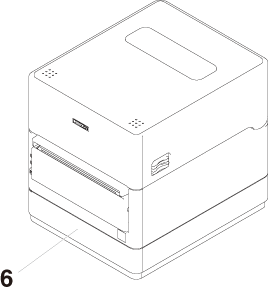

Operation panel

The operation panel includes 2 LEDs and 1 key.

- 1.Power LED

- Turns on when the power is turned on and turns off when the power is turned off.

- 2.Status LED

- Turns on or flashes in green, red, and amber depending on the printer status.

| Color |

Lights/flashes |

Status |

| Green |

On |

Printer is online |

| Flashes |

Receiving data |

| Amber |

On |

Startup |

| Red, green, amber |

Flashes |

Error or alarm |

- 3.FEED key

- Paper feeds while the key is pushed.

Enter the test printing or memory switch setting mode.

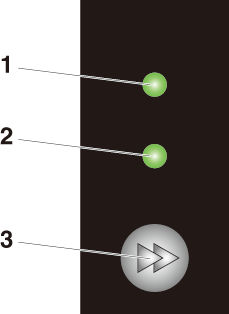

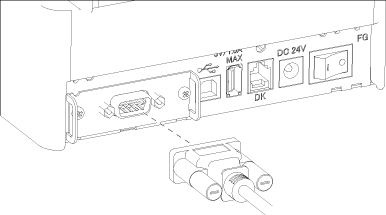

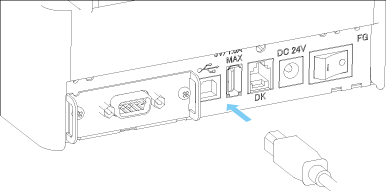

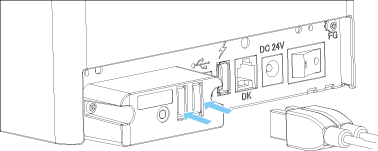

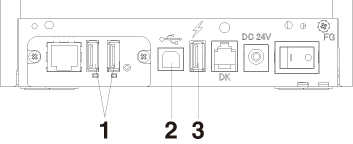

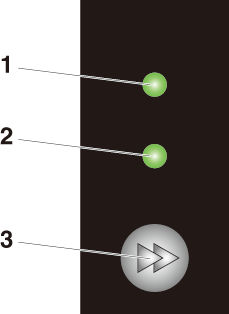

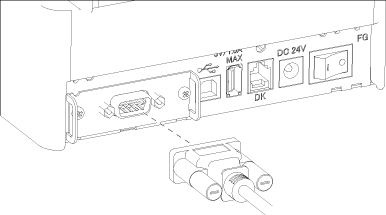

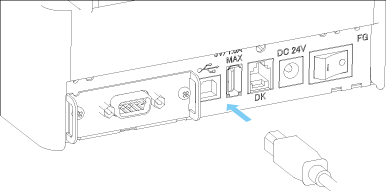

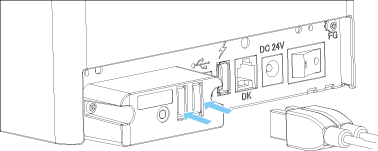

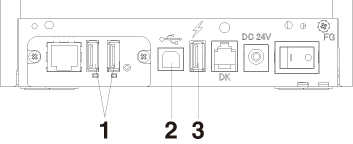

Rear connectors (serial interface example)

- 1.USB interface

- 2.USB power supply connector

- Supplies power to USB devices.

- 3.Cash drawer kick-out connector

- Connect to the cable from the cash drawer.

- 4.DC jack

- Connects to the included AC adapter.

- 5.Power switch

- Turns the printer power supply on and off.

- 6.USB cable clamp attachment holes

- USB cable clamps can be attached.

- 7.Ground wire attachment screw

- Screw in the ground wire from the drawer to attach it.

- 8.Interface connector (serial, USB, etc.)

- Connect to the interface cable.

Inner area of the top cover

- 1.Thermal head

- Prints characters and graphic data on paper (paper rolls).

- 2.Upper sensor

- This sensor detects the media position.

- 3.Media damper

- When using roll media, absorbs tension generated by media feed operations to prevent

print errors.

- 4.Bottom sensor

- This sensor detects the media position.

- Devices are equipped with lock mechanisms.

- 5.Fixed left-side media guide

- 6.Paper guide (Movable right-side paper guide)

- 7.Platen roller

- This roller transports media.

- 8.Head balance adjustment slider

- 9.Manual cutter

- 10.Paper partition

- Move the partition to a position suitable for the paper width.

- 11.Paper partition position adjustment button

- With this button pushed, move the paper partition to the left or right.

- 12.Paper width scale

- 13.Paper near-end (PNE) sensor

- Detects when the paper is near the end of the roll.

- 14.Paper near end sensor selector lever

- Adjust the position of the sensor to determine when it detects the end of the paper

is near.

- 15.Paper end (PE) sensor

- Detects when there is no paper. Printing stops when this sensor detects there is no

paper.

- 16.Media shaft mounting groove

- When using a media shaft, attach it to this section.

Other Built-in Functions

- Buzzer

- Buzzes when errors occur or when operations or command operations are performed.

- User memory

- You can save user-defined logo and character data in this memory. Data remains stored

in this memory even if the printer is turned off. For information on how to save data,

refer to the Command Reference.

- Memory switch

- Setting of various kinds of functions can be stored in memory. Settings remain stored

in the memory even if the printer is turned off.

- USB-linked power OFF (When MSW6-3 of memory switch is set to ON)

- When the printer is connected to PC by USB, the printer becomes the state of USB-linked

power OFF after 3 seconds when PC power off or USB connection lost.

This mode is canceled when the PC is turned back on or when a USB connection is established.

CAUTION

- Since the POWER LED is unlit when the state of USB-linked power OFF, it cannot be identified from the

power OFF.

- Pressing POWER while USB power is off does not turn on power immediately.

After a while, USB power supply OFF is canceled and pressing POWER turns on power

normally.

- Paper saving functions

- Memory switches MSW8-3 through MSW8-4 can be used to configure the settings below,

which save paper.

- Top margin suppression

- The printer back feeds the paper before printing which reduces the blank space at

the top edge of the paper.

The back feed amount can be specified.

- Line gap reduce

- Automatically compresses the linefeed amount between lines. The compression ratio

can be specified.

CAUTION

- Remove the partially cut paper before performing back feed for starting printing.

The cut paper may be torn off in the next printing process, which may cause a problem.

- Auto side shift (MSW8-6)

- This function dissipates heat load during frequent heat generation by a vertical ruled

line or other specific head heating element.

- If no data is received within 15 seconds after each cut or print, the print position is automatically slid N* dots

to the right. The original print position is returned to at the next slide timing.

- * N is the MSW8-6 setting value.

CAUTION

- If the right margin is too narrow, this may result in some print characters being

cut off.

- This function is disabled under initial settings.

- To enable this function, use MSW8-6 to specify an appropriate value for the maximum

slide amount.

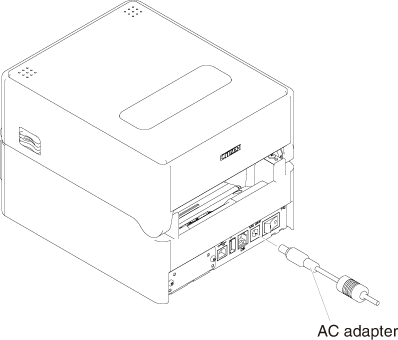

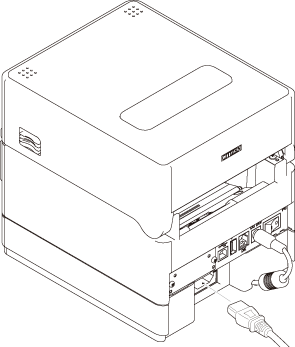

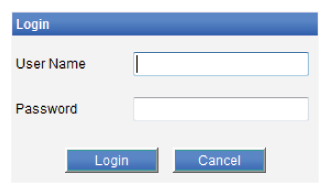

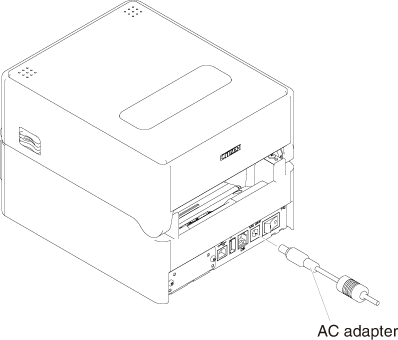

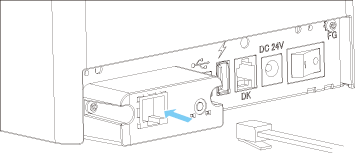

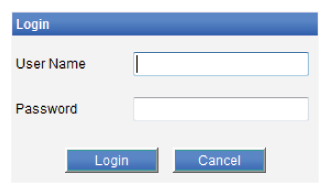

Connecting the AC Power Cord

For standard models

- 1.Turn off the power.

- 2.Insert the DC plug on the output side of the AC adapter into the DC jack in the printer.

- 3.Insert the plug of the AC cord into an electrical outlet.

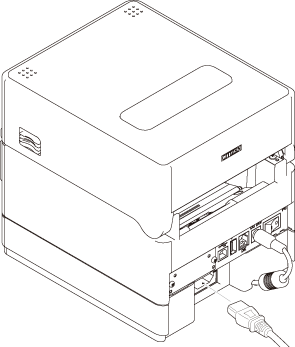

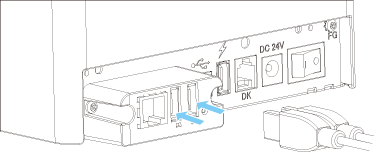

For models with stored AC adapter

- 1.Turn off the power.

- 2.Insert the plug of the AC cord into the AC port.

- 3.Insert the plug of the AC cord into an electrical outlet.

CAUTION

- Use only the specified AC adapter.

- Always hold the AC adapter’s cable connector by the connector when removing or inserting

it.

- Use an AC power source that does not also supply power to equipment that generates

electromagnetic noise.

- Pulling on the AC power cord may damage it, cause a fire, electric shock, or break

a wire.

- If a lightning storm is approaching, unplug the AC power cord from the electric outlet.

A lightning strike may cause a fire or electric shock.

- Keep the AC power cord away from heat generating appliances. The insulation on the

AC power cord may melt and cause a fire or electric shock.

- If the printer is not going to be used for a long time, unplug the AC power cord from

the electric outlet.

- Place the AC power cord so that people do not trip on it.

- Make sure of the following before connecting the AC adapter.

The power switch on the printer is turned off.

The plug of the AC cord is removed from the electrical outlet.

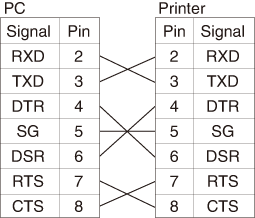

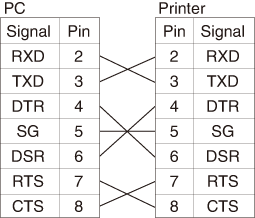

Serial Interface Board

Data can be exchanged by serial communication.

Connecting the Interface Cable

- 1.Turn off the power.

- 2.Confirm the orientation of the interface cable and connect it to the port.

- 3.Insert the other connector firmly into the interface port of the host computer.

CAUTION

- When disconnecting the cable, always hold the connector.

- Place the interface cable so that people do not trip on it.

- Do not connect multiple interfaces at the same time.

Use a serial cable with the connection layout shown below.

9-pin (female) - 9-pin (female) cable

USB Interface

Data can be exchanged by USB communication.

Specifications

| Standard |

USB 2.0 specification-compliant |

| Communication speed |

Supports 12 Mbps (Full-Speed) transfer |

Connecting the Interface Cable

- 1.Turn off the power.

- 2.Confirm the orientation of the interface cable and connect it to the port.

- 3.Insert the other connector firmly into the interface port of the host computer.

CAUTION

- When disconnecting the cable, always hold the connector.

- Place the interface cable so that people do not trip on it.

- Do not connect multiple interfaces at the same time.

- Be careful not to insert the USB cable into the cash drawer kick-out connector.

- To connect more than one printer to a single computer by USB, you must change the

serial number of the USB interface.

- There are models with a USB port on the interface board side.

With such a model, do not connect USB cables to both the printer main unit side and

interface board side.

If USB cables are connected to both, priority will be given to communication of the

one connected to the port on the main unit side.

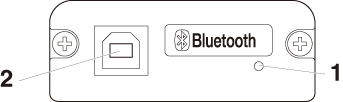

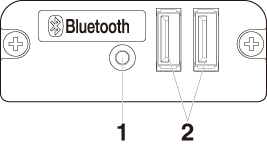

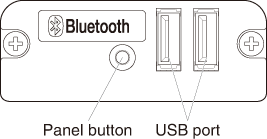

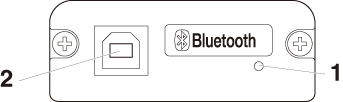

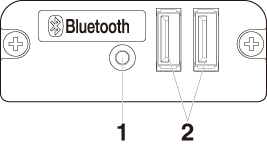

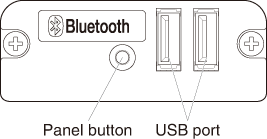

Bluetooth Interface Board

Names of parts

- 1.Status LED

- The Bluetooth communication/connection/error status is indicated by this LED.

- 2.USB connector

- Data can be exchanged by USB communication.

CAUTION

- When using this interface board as a USB interface, do not connect USB cables to both

the main unit side and interface board side.

If USB cables are connected to both, priority will be given to communication of the

one connected to the connector on the main unit side.

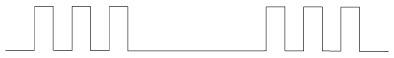

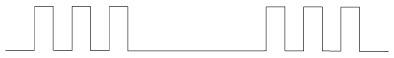

Bluetooth status LED

| Status |

Description |

LED Status |

Detection

standby

(Discoverable)

|

Standing by for

detection and

connection

|

|

Connection

standby

(Connectable)

|

Standing by for

connection

|

|

| iOS connection |

Data session unopened |

|

| Communicating |

iOS: data session opened

Other OS: connection established and communication in progress

|

|

| Error |

Error or settings being configured |

Unlit |

Pairing operation

You need to perform the operations below the first time you establish a Bluetooth

connection for Bluetooth data communication.

- 1.Detect Bluetooth devices

- 2.Configure pairing settings

- 1.Detecting Bluetooth devices

- Confirm that Bluetooth is enabled on the host PC before searching for Bluetooth devices.

- This product will show up as "CT-S4500_XX"(XX is last 2 digits of unique Serial Number.) when it is detected.

- Select this product from among the detected devices.

- Note: You can search for devices and change the names.

- When memory switch MSW13-5 is set to "No Response," nothing is displayed by device

detection.

- You can temporarily switch this setting to device detection (detect mode) by opening

the paper cover and holding down the FEED button for two seconds. Detect mode is exited when the connection between the host

PC is terminated.

- 2.Configuring pairing settings

- Normally, selecting the printer during device detection will transition directly to

pairing settings.

CAUTION

- Some host PC configurations and models may not transition directly to pairing settings

after the printer is selected during device detection.

The operation required to configure pairing settings depends on whether SSP (secure

simple pairing) is enabled on the host PC.

If SSP is enabled on the host PC, pairing can be achieved without additional operations.

If SSP is disabled on the host PC, you will be prompted to input a passkey.

Input the passkey as described below.

Passkey

Last four digits of the address on the self test printout (Letters A through F are

uppercase)

Example: If the address is 01:23:45:67:89:AB the passkey is 89AB.

If you delete paring information from the host PC without deleting the corresponding

pairing information on the printer, the printer may not show up if you detect devices

again with the host PC.

To delete printer pairing information, open the paper cover and then hold down the

FEED button for five seconds.

Deleting pairing information on the printer will put the printer into discovery mode.

Auto reconnection

With iOS device Bluetooth communication, a connection between a paired iOS device

and the printer is not automatically restored after it is lost. However, when auto

reconnection is enabled, the printer tries to reconnect with an iOS device after two-way

communication is enabled and automatically restores the connection.

CAUTION

- This function is enabled when shipped from the factory. (MSW13-6)

Auto reconnection can take some time to connect when the host is not an iOS device.

- Even if the partner device is an iOS device, the conditions below can interfere with

the auto reconnection function.

- When you want Bluetooth communication to cut off after printing is complete

- When there are multiple iOS devices printing on the same printer

- Under such conditions, disable auto reconnection.

Enabling and disabling auto reconnect

During self test, press the FEED button 3 times -> Auto reconnect = Valid

During self test, press the FEED button 4 times -> Auto reconnect = Invalid

At the end of self test, new setting will be printed as Auto reconnect [Valid] or

[Invalid].

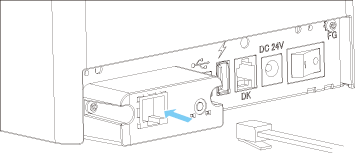

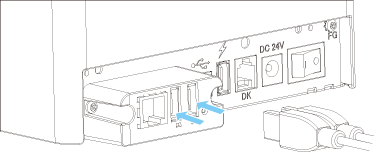

Bluetooth USB host interface board

In addition to printer control via Bluetooth communication, Bluetooth USB host interfaces

can control peripheral devices connected via a USB port.

Connecting a Peripheral Device

- 1.Turn off the power.

- 2.Connect the cable of a peripheral device to this port.

CAUTION

- A peripheral device cannot be controlled if it is connected to the USB power supply

port.

Be sure to connect it to the USB port of the interface board.

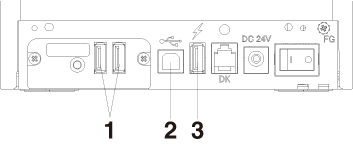

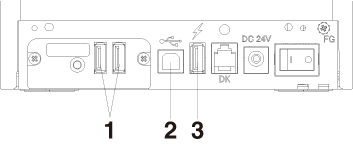

Connecting a USB Device

The function assigned to each USB port differs.

Connect the USB device to be connected to the correct place in reference to the following

figure.

- 1.For peripheral device control

- Connect a peripheral device.

The connected peripheral device can be controlled.

- 2.For host computer communication

- Connect with a host computer.

The printer and host computer will communicate via USB.

- 3.For supplying power

- Connect a mobile device or other USB device.

Power can be supplied to a connected USB device.

- * This port does not support USB data communication.

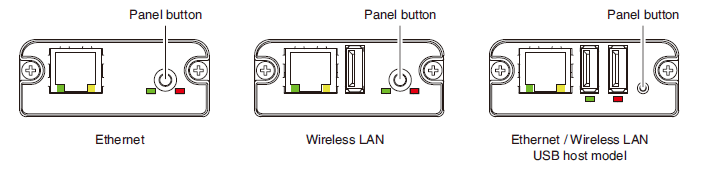

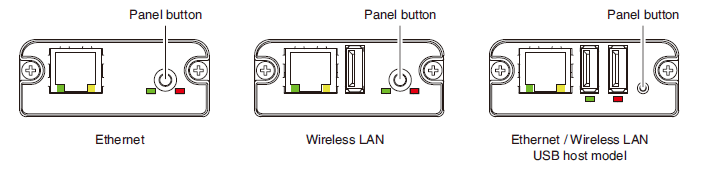

Names of parts

- 1.Panel button

- Control this interface board.

- 2.USB 2 port

- Connect a peripheral device.

CAUTION

- Only connect peripheral devices specified by our company to the USB port.

- Only plug in/remove peripheral devices when the printer power is turned off.

Pairing operation

You need to perform the operations below the first time you establish a Bluetooth

connection for Bluetooth data communication.

- 1.Detect Bluetooth devices

- 2.Configure pairing settings

- 1.Detecting Bluetooth devices

- Confirm that Bluetooth is enabled on the host PC before searching for Bluetooth devices.

- This product will show up as "CT-S4500_XX"(XX is last 2 digits of unique Serial Number.) when it is detected.

- Select this product from among the detected devices.

- Note: You can search for devices and change the names.

- When memory switch MSW13-5 is set to "No Response," nothing is displayed by device

detection.

- With these settings, pressing and holding the panel button for at least three seconds

and then pressing it twice more places the product temporarily in a state where it

will be found in device searching (discovery mode).

Discovery mode cancels when the product is connected to a host PC.

- 2.Configuring pairing settings

- Normally, selecting the printer during device detection will transition directly to

pairing settings.

CAUTION

- Some host PC configurations and models may not transition directly to pairing settings

after the printer is selected during device detection.

The operation required to configure pairing settings depends on whether SSP (secure

simple pairing) is enabled on the host PC.

If SSP is enabled on the host PC, pairing can be achieved without additional operations.

If SSP is disabled on the host PC, you will be prompted to input a passkey.

Input the passkey as described below.

Passkey

Last four digits of the address on the self test printout (Letters A through F are

uppercase)

Example: If the address is 01:23:45:67:89:AB the passkey is 89AB.

If you delete paring information from the host PC without deleting the corresponding

pairing information on the printer, the printer may not show up if you detect devices

again with the host PC.

When deleting pairing information, press and hold the panel button for at least three

seconds, and after the buzzer sounds, press it four more times.

If successful, “Erase Bonded Device” is printed.

Deleting pairing information on the printer will put the printer into discovery mode.

Auto reconnection

With iOS device Bluetooth communication, a connection between a paired iOS device

and the printer is not automatically restored after it is lost. However, when auto

reconnection is enabled, the printer tries to reconnect with an iOS device after two-way

communication is enabled and automatically restores the connection.

CAUTION

- This function is enabled when shipped from the factory. (MSW13-6)

Auto reconnection can take some time to connect when the host is not an iOS device.

- Even if the partner device is an iOS device, the conditions below can interfere with

the auto reconnection function.

- When you want Bluetooth communication to cut off after printing is complete

- When there are multiple iOS devices printing on the same printer

- Under such conditions, disable auto reconnection.

Enabling and disabling auto reconnect

During self test, press the FEED button 3 times -> Auto reconnect = Valid

During self test, press the FEED button 4 times -> Auto reconnect = Invalid

At the end of self test, new setting will be printed as Auto reconnect [Valid] or

[Invalid].

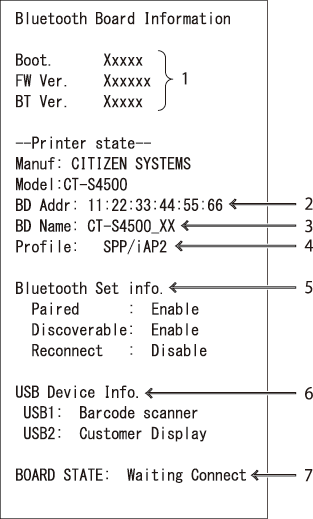

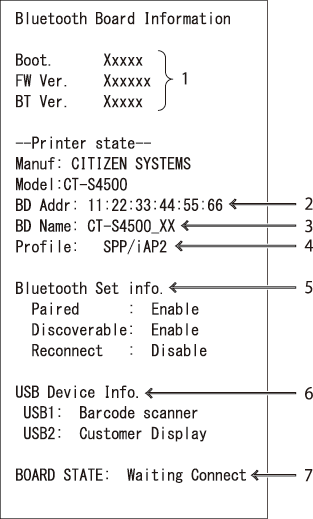

Panel button operation

Use the panel button on the rear of the Bluetooth board to operate this board.

- BT device search (MSW13-5) settings

- 1.Press and hold the panel button to turn on printer power.

- 2.Press the panel button within one second after starting the printer.

- The setting changes in accordance with the number of times you press the panel button.

- Two presses: Discovery possible

- Three presses: No response

- After these operations the printer restarts.

- Print the interface board state

- After starting the printer, pressing the panel button once prints the interface board

state.

Print example

- 1.Board firmware version

- 2.Address of equipped Bluetooth module

- 3.Bluetooth name

- 4.Response profile in Bluetooth transmission

- 5.Bluetooth setting state

- 6.Name of connected USB device (“No connection” is displayed when there is no connection)

- 7.Board status

Ethernet (LAN)/Wireless LAN Interface Board

This section provides an overview of the interface board. For details on this board,

including explanations about the USB host function and XML peripheral device support,

refer to the separate manual.

Connecting the Interface Cable

- 1.Turn off the power.

- 2.Confirm the orientation of the interface cable and connect it to the port.

- 3.Connect the other connector to a hub, router, or similar device.

CAUTION

- When disconnecting the cable, always hold the connector.

- Place the interface cable so that people do not trip on it.

- Do not connect multiple interfaces at the same time.

- Hold the connector of the LAN cable perpendicular and straight when connecting or

disconnecting it. Doing it at an angle may cause the connector to misconnect.

Connecting a Peripheral Device

- 1.Turn off the power.

- 2.Connect the cable of a peripheral device to this port.

CAUTION

- A peripheral device cannot be controlled if it is connected to the USB power supply

port.

Be sure to connect it to the USB port of the interface board.

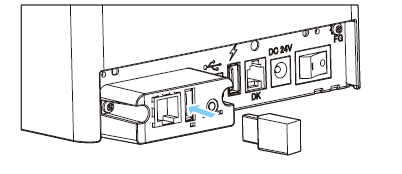

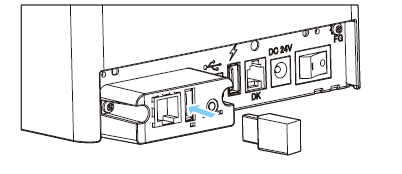

Connecting the wireless LAN adapter

- 1.Turn off the power.

- 2.Connect the wireless LAN adapter to the connector.

Notes

- The wireless LAN cannot be used when connected to the USB power supply connector.

Be sure to connect it to the USB connector on the interface board.

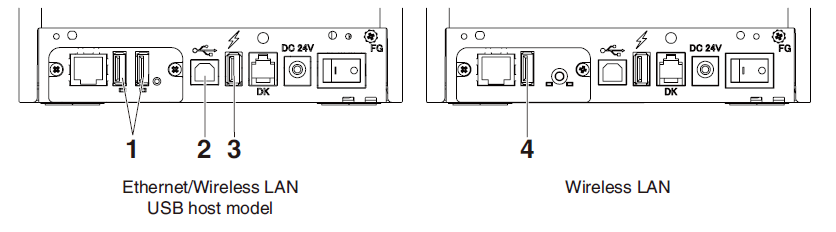

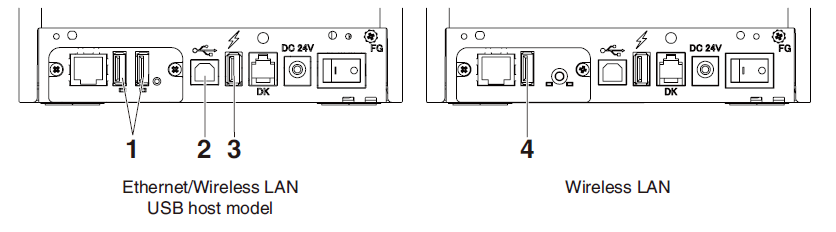

Connecting a USB Device

The function assigned to each USB port differs.

Connect the USB device to be connected to the correct place in reference to the following

figure.

- 1.For peripheral device control

- Connect a peripheral device.

The connected peripheral device can be controlled.

- 2.For host computer communication

- Connect with a host computer.

The printer and host computer will communicate via USB.

- 3.For supplying power

- Connect a mobile device or other USB device.

Power can be supplied to a connected USB device.

- * This port does not support USB data communication.

- 4.For wireless LAN adapter connection

- Connect a wireless LAN adapter.

Panel button operation

Board operations are performed using the panel button on the rear of the LAN board.

- Enabling LAN connection

- Turn on the printer. Operation of this board will start about 20 seconds later.

- Printing LAN setup information

- Press the panel button.

- Entering setting mode

- Hold down the panel button. A buzzer* will sound once to indicate that setting mode

has been entered.

- You can use setting mode to read factory settings.

- If no operation is performed for 3 seconds in configuration mode, the mode switches

back to normal mode.

- Returning to factory settings

- Enter the board setting mode, and then hold down the panel button. This returns the

board to its factory settings.

CAUTION

- The board will automatically restart after this operation is complete. After clearing

settings, you will need to re-configure network settings.

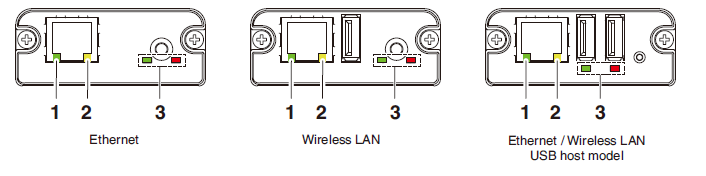

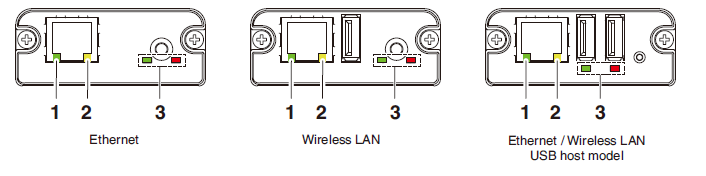

LED Functions

The tables below explain how to interpret LED indications.

Web Manager

The interface board has a Web Manager function that can be used to connect to the

board with a web browser and change board settings.

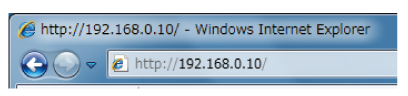

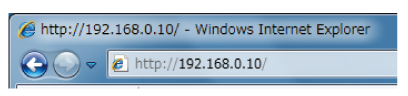

Starting up Web Manager

- 1.Start up a web browser.

- 2.In the address field, input the board's IP address and then press [Enter].

HOME Screen

This is the Web manager home screen.

The following screen is an example for a wireless LAN.

Here, press the [CONFIG] button.

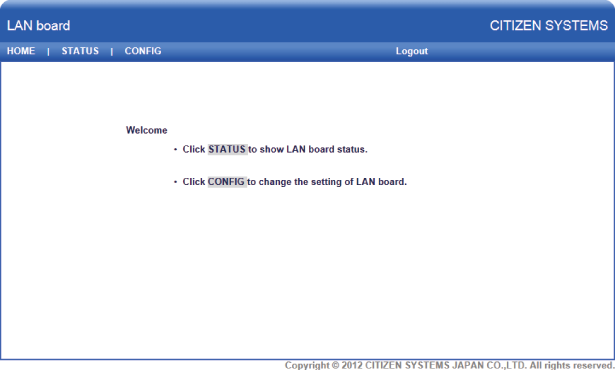

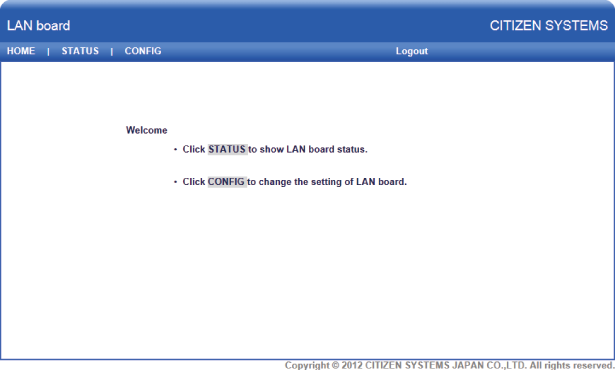

CONFIG Screen

This will display the Login dialog box shown below. Log in as an administrator and

then configure interface board settings.

- User Name

- Input a board administrator user name. (Initial setting: admin)

- Password

- Input the administrator user password. (Initial setting: admin)

- [Login] button

- After inputting an administrator user name and password, click the [Login] button.

This displays the setting screen.

- For details about settings, refer to the separate manual.

USB Power Supply Port

Power (max. 2.1 A) can be supplied to a mobile device or other USB device by connecting

the cable of the USB device to the power supply port.

Connecting Mobile Device or Other Device

- 1.Turn off the power.

- 2.Connect the cable of a mobile device or other device to the USB power supply port.

Connecting a USB Device

The function assigned to each USB port differs.

Connect the USB device to be connected to the correct place in reference to the following

figure.

- 1.For peripheral device control

- Connect a peripheral device.

The connected peripheral device can be controlled.

- 2.For host computer communication

- Connect with a host computer.

The printer and host computer will communicate via USB.

- 3.For supplying power

- Connect a mobile device or other USB device.

Power can be supplied to a connected USB device.

- * This port does not support USB data communication.

CAUTION

- This port does not support USB data communication.

- Power may not be able to be supplied depending on the USB device to be used.

In this case, use the device’s dedicated AC adapter or battery charger.

- A USB cable for power supply is not included with this product.

Use a commercially available USB cable or the one that comes with the USB device.

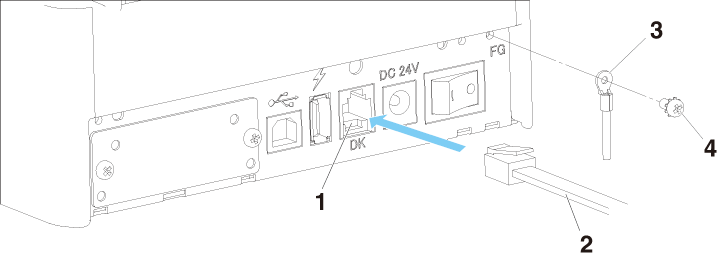

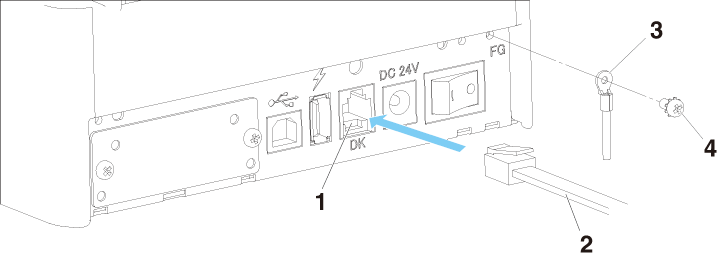

Connecting the Cash Drawer

- 1.Turn off the power.

- 2.Confirm the orientation of the cash drawer kick-out cable connector and connect it

to the cash drawer kick-out connector at the back of the printer.

- 3.Remove the screw for the ground wire.

- 4.Screw the cash drawer’s ground wire to the body of the printer.

- 1.Cash drawer kick-out connector

- 2.Cash drawer kick-out cable connector

- 3.Ground wire

- 4.Screw for ground wire

|

CAUTION

- Connect only the cash drawer kick-out cable to this connector. (Do not connect a telephone

line.)

- Signals cannot be output from the cash drawer kick-out connector while printing.

- Hold the connector of the drawer kick cable perpendicular and straight when connecting

or disconnecting it. Doing it at an angle may cause the connector to misconnect.

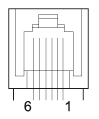

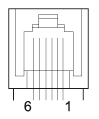

- (1)Connector pin configuration

| No. |

Signal |

Function |

|

| 1 |

FG |

Frame ground |

| 2 |

DRAWER1 |

Cash drawer 1 drive signal |

| 3 |

DRSW |

Cash drawer switch input |

| 4 |

VDR |

Cash drawer drive power supply |

| 5 |

DRAWER2 |

Cash drawer 2 drive signal |

| 6 |

GND |

Signal ground (common ground on circuits) |

Applicable connector: RJ-11

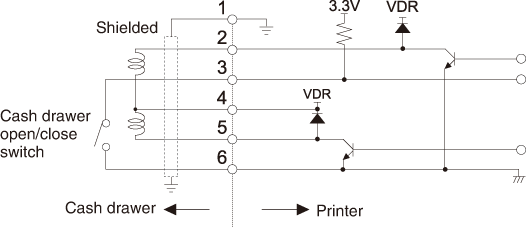

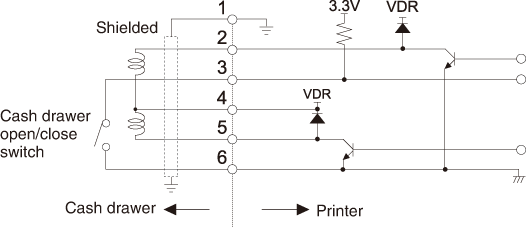

- (2)Electric characteristics

- 1)Drive voltage: 24 VDC

- 2)Drive current: Approx. 1 A max. (not to exceed 510 ms.)

- 3)DRSW signal: Signal levels: “L” = 0 to 0.5 V, “H” = 3 to 5 V

- (3)DRSW signal

- Status can be tested by commands.

- (4)Drive circuit

Cash drawer kick-out connector

CAUTION

- Cash drawers 1 and 2 cannot be operated at the same time.

- The solenoid used for the cash drawer should be 24 Ω or more. Do not allow the electric

current to exceed 1 A. Excessive current could damage or burn out the circuits.

Precautions for Installing the Printer

This printer can only be positioned horizontally. It cannot be positioned vertically

or on a wall.

|

|

| Horizontal position |

Vertical position |

CAUTION

- Do not use the printer under the following conditions.

- Avoid locations subject to vibration or instability.

- Locations that are very dirty or dusty.

- Avoid locations where the printer is not level.

- The printer may fall and cause an injury.

- The quality of printing may deteriorate.

- Oriented other than as specified.

- Malfunction, failure, or electric shock may result.

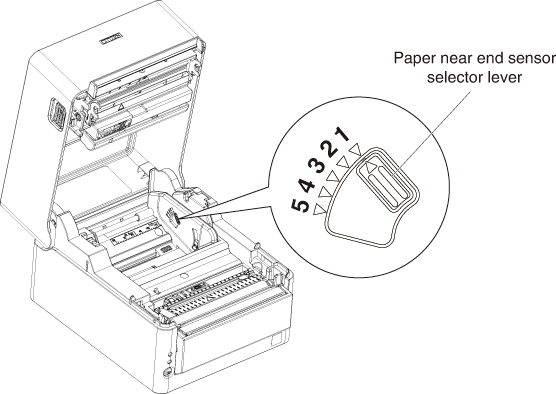

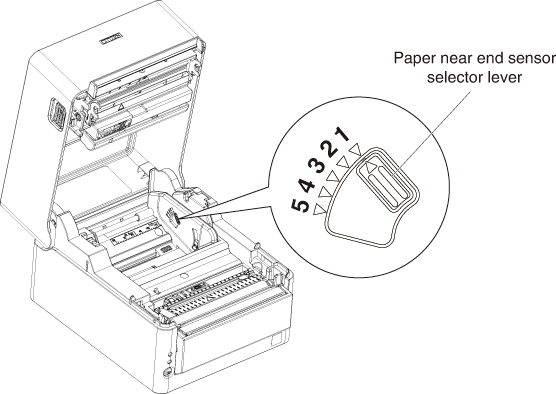

Adjusting the Paper Near-end Sensor

Change the settings of the paper near-end sensor to set the position at which the

near-end of the paper is detected.

- 1.Open the top cover.

- 2.Adjust the sensor position by moving the paper near end sensor selector lever while

gently pushing it in. The sensor position differs as follows depending on the core

outer diameter of the roll paper to be used.

(Unit: mm)

| Sensor position |

Paper roll outer diameter when near-end is detected |

Maximum core outer diameter of roll paper to be used |

| 1* |

Approximately ø21.0 |

ø18.0 |

| 2 |

Approximately ø24.5 |

ø21.5 |

| 3 |

Approximately ø28.0 |

ø25.5 |

| 4 |

Approximately ø31.5 |

ø28.0 |

| 5 |

Approximately ø35.0 |

ø32.0 |

Notes:

*Sensor position when shipped from the factory. However, factory settings differ depending

on the destination market.

CAUTION

- When the media shaft will be used, the roll diameter detection function of the paper

near end sensor will not function properly so disable MSW2-8 (PNE sensor).

- When the memory switch settings are as follows, the paper near-end sensor is disabled.

MSW4-4 (paper selection): Black mark paper/label media

MSW4-5 (paper position detection method): Label gap detection

- When the memory switches are set as follows, the PNE sensor may not function properly

due to factors such as the shape of the shaft center of the roll paper.

If that happens, disable MSW2-8 (PNE sensor).

MSW4-4 (paper selection): Black mark paper / label paper

MSW4-5 (paper position detection method): Black mark detection

- The diameter of the roll of paper that is detected is an estimate. Some variations

may occur depending on the paper.

- When using the supplied sample roll paper, align the sensor position to position 5.

The paper near end may not be able to be detected correctly with the default sensor

position.

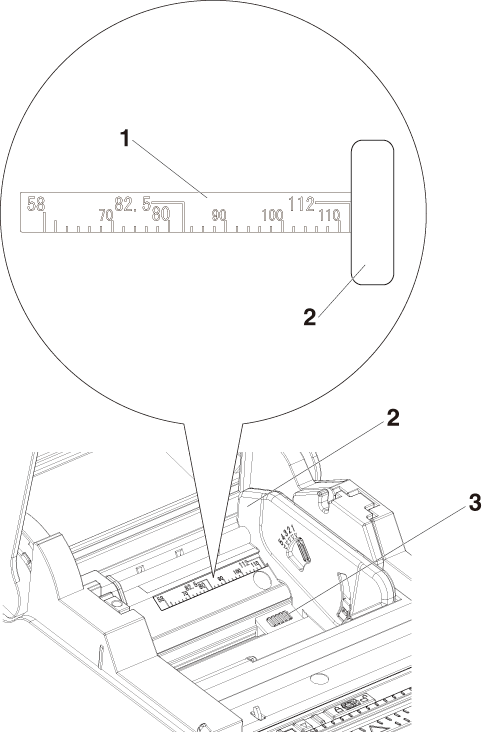

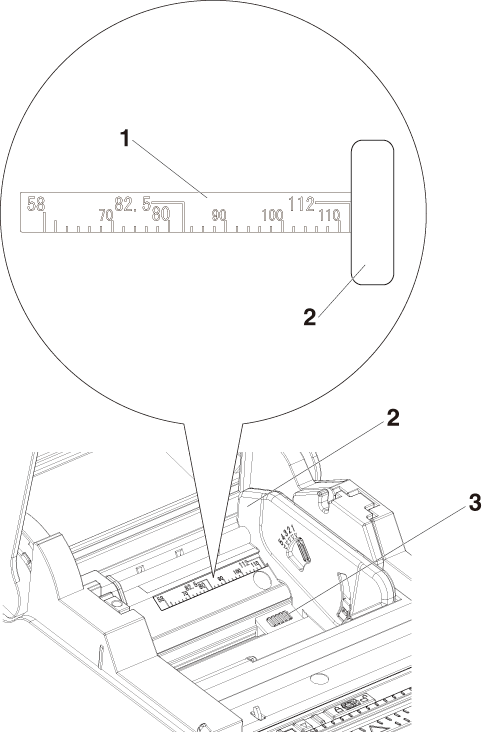

Roll paper partition

When using roll paper narrower than 112 mm in width, move the paper partition to a

suitable position.

- 1.Turn off the power.

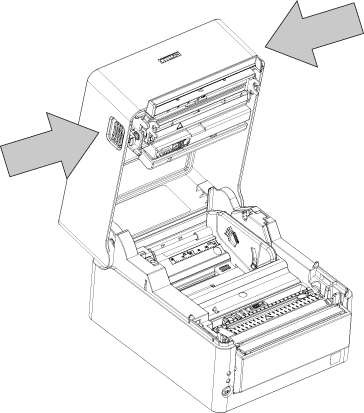

- 2.Press the cover release buttons on both the right and left sides to open the top cover.

- 3.Move the paper partition left or right while pressing the paper partition position

adjustment button to align it with the paper width position on the paper width scale.

- 4.Change the print area width while referring to “Manual Setting of Memory Switches.”

- 1.Paper width scale (unit: mm)

- 2.Paper partition

- 3.Paper partition position adjustment button

CAUTION

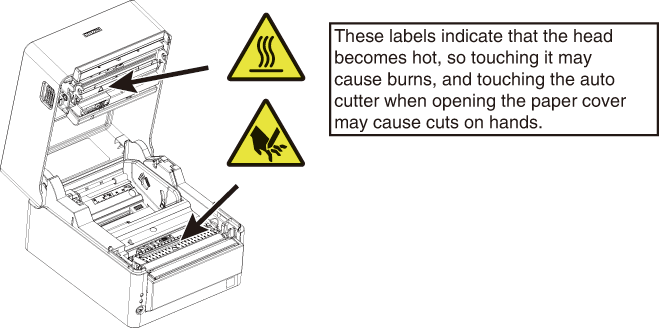

- When opening the top cover, be careful not to touch the entrance of the blade of the

auto cutter.

- The print head is very hot immediately after printing. Be careful not to touch it

with your hands.

- Do not touch the print head with bare hands or metal objects.

- When narrow paper will be used for a long period of time, use the printer with only

paper of that width.

If the width is changed to that for wide paper after using the printer with narrow

paper for a long period of time, paper feeding and printing may not be performed properly.

- Use thermal roll paper with a width of at least 80 mm. Using paper that is less than

80 mm wide is not recommended.

- Do not move the paper partition while the paper partition position adjustment button

is not pressed. Doing so may cause damage.

- If the paper partition position is not appropriate, improper operation and printing

may occur.

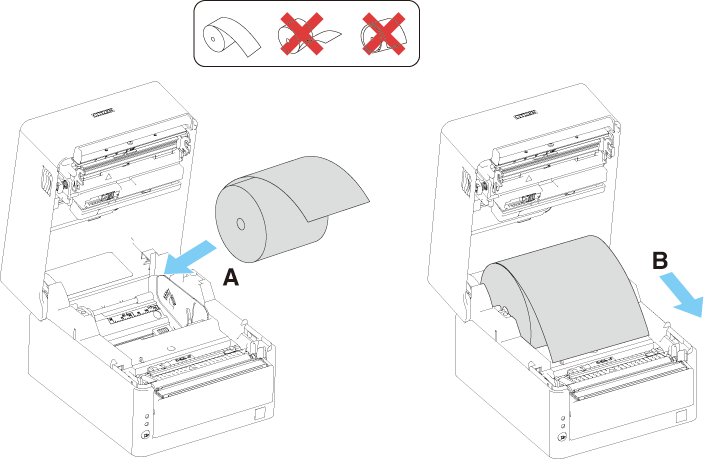

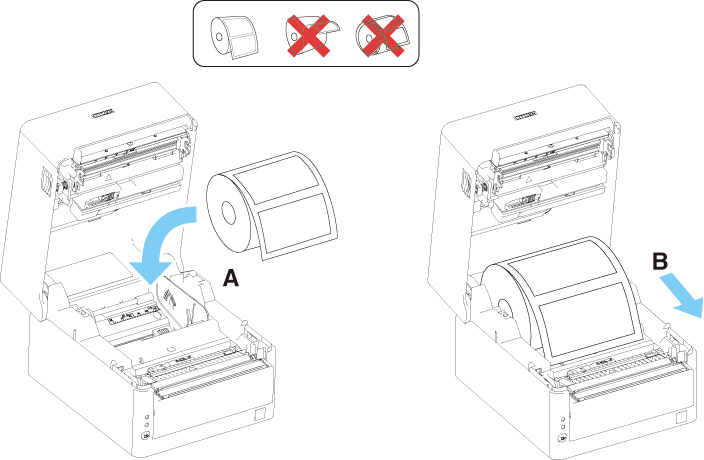

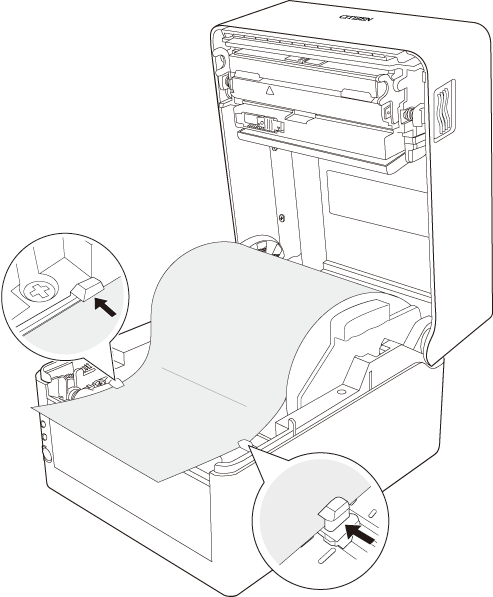

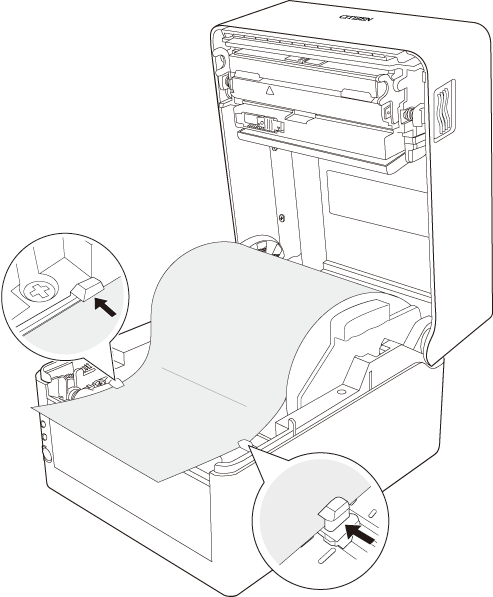

Loading Paper

- 1.Turn on the power.

- 2.Press the cover release buttons on both the right and left sides to open the top cover.

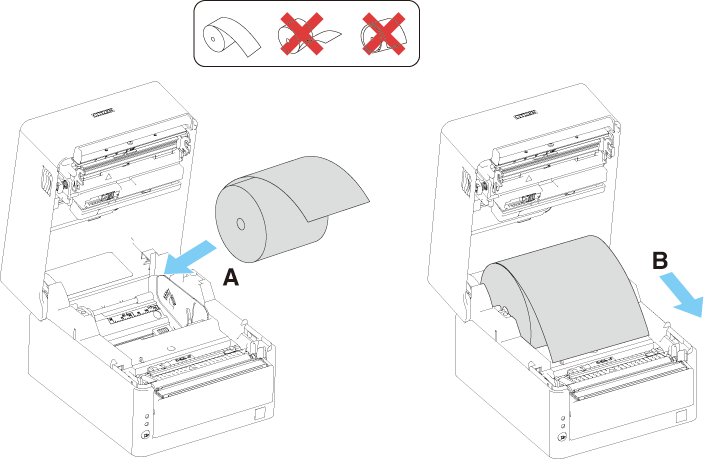

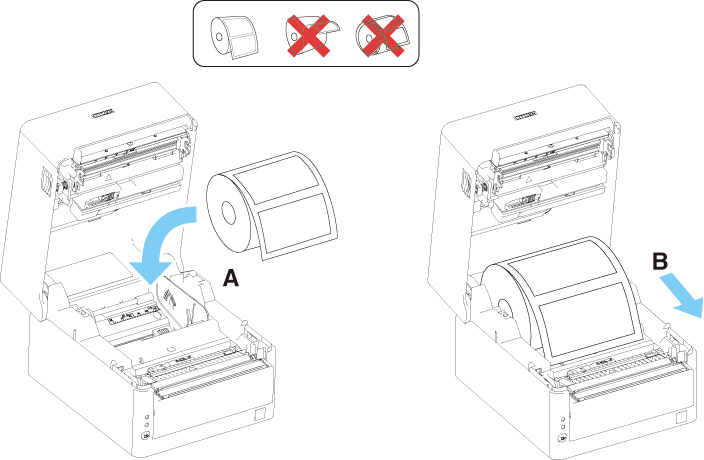

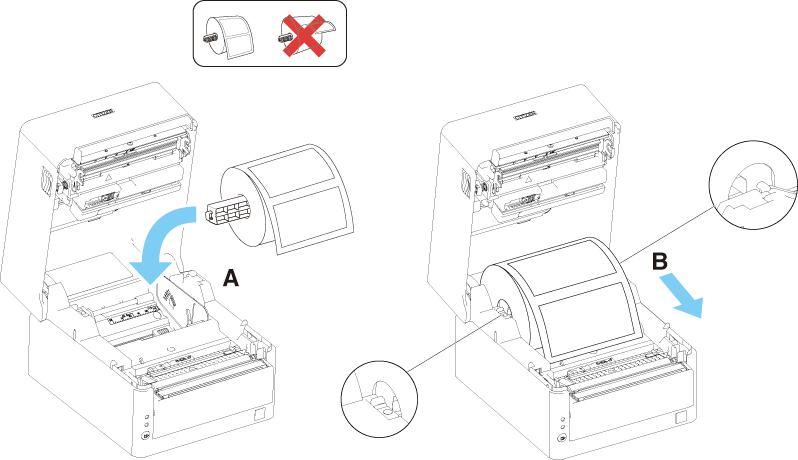

- 3.Load the roll paper with the printable side of the paper facing outward as shown by

arrow A and with no slack.

- 4.Pull a few centimeters of paper straight out in the direction of arrow B.

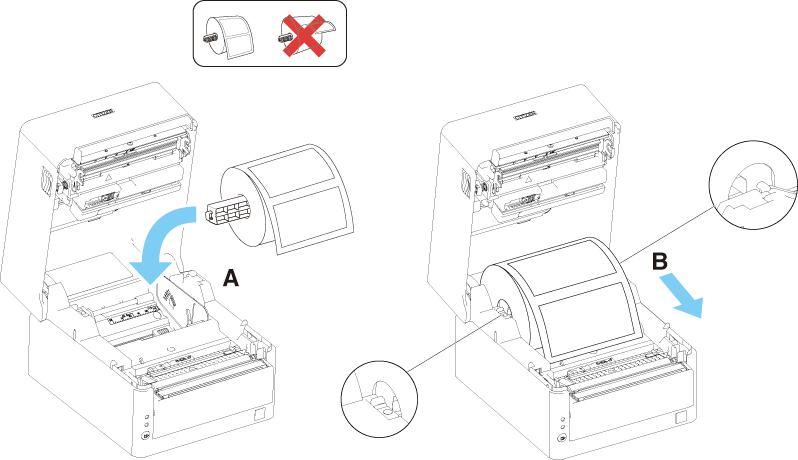

- Label media (when using a media shaft)

CAUTION

- When opening the paper cover, be careful not to touch the entrance of the blade of

the auto cutter.

- The print head is very hot immediately after printing. Be careful not to touch it

with your hands.

- Do not touch the print head with bare hands or metal objects.

- Always use the specified types of paper rolls.

- Confirm that the paper roll is set correctly.

- If the paper is skewed and not coming straight out of the paper cover, open it and

straighten the paper.

- Be careful of paper cuts while loading the paper.

- Do not pass paper through the rear of the printer.

- 5.Make sure the paper is flush with the left media guide and then adjust the position

of the right media guide to match the paper width.

- From the front of the printer, set in front of the edge of media by approximately

10 mm.

CAUTION

- If force is used to push the right movable media guide against the paper, improper

feeding of the paper may occur, which may have an impact on printing.

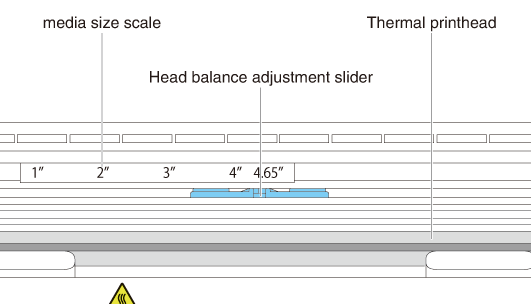

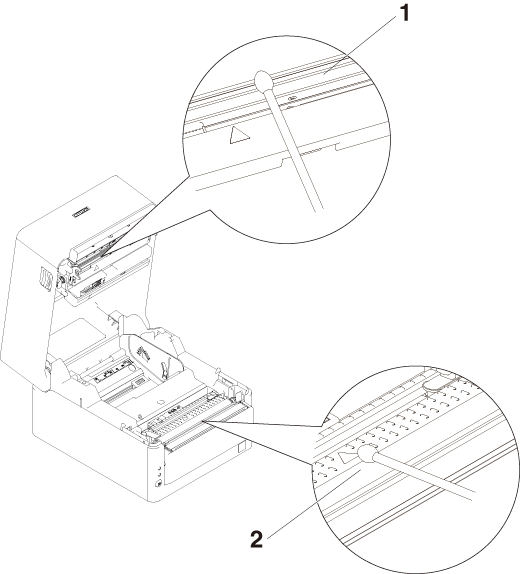

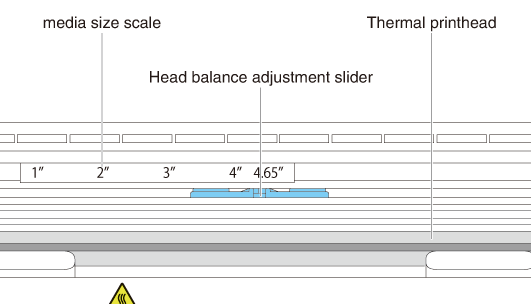

- 6.Use something with a sharp point such as the tip of a pen to slide the head balance

adjustment slider located near the thermal head left or right along the paper size

scale (inches) so that the position of the notch in the slider matches the paper width.

CAUTION

- Use this printer with the width adjusted to at least 2 inches.

- Adjust the head pressure horizontal balance carefully so as not to damage the thermal

head.

Damaged thermal heads will result in poor printing, paper jams, and malfunction.

- When using paper with a width of 80 mm or more in a very hot and humid environment,

we recommend setting this within the range of 3.5” to 4.65”.

- 7.Close the top cover.

CAUTION

- Press the push marks on left and right sides at the top of the top cover and ensure

that the top cover hooks on each side lock securely.

If the top cover is not securely locked, this may cause print errors, paper jams,

and malfunction.

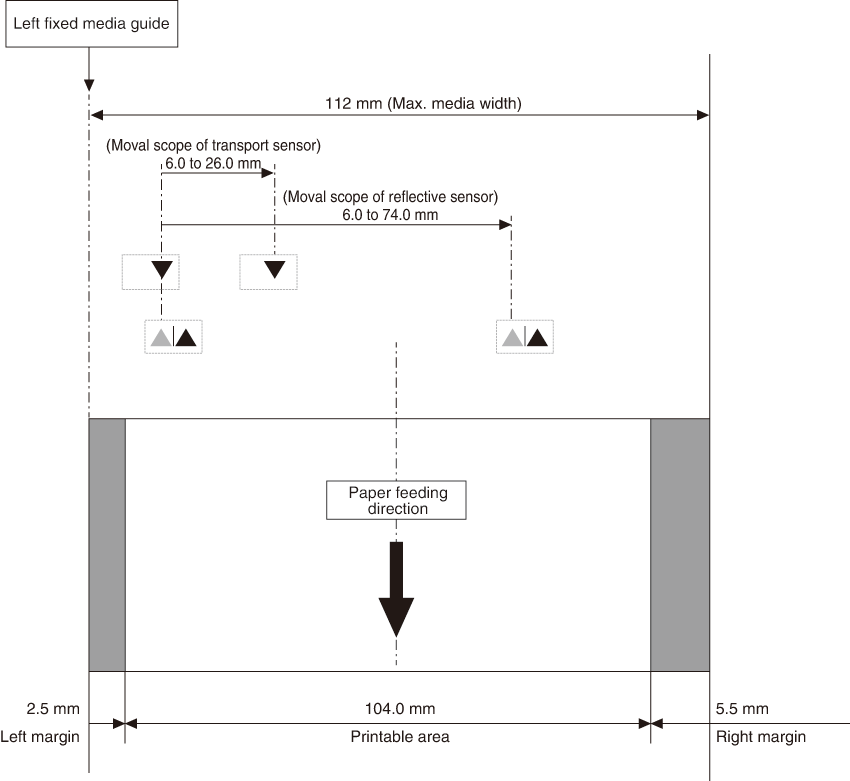

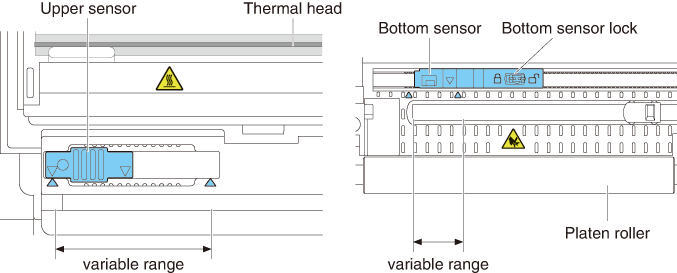

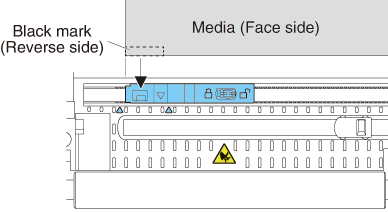

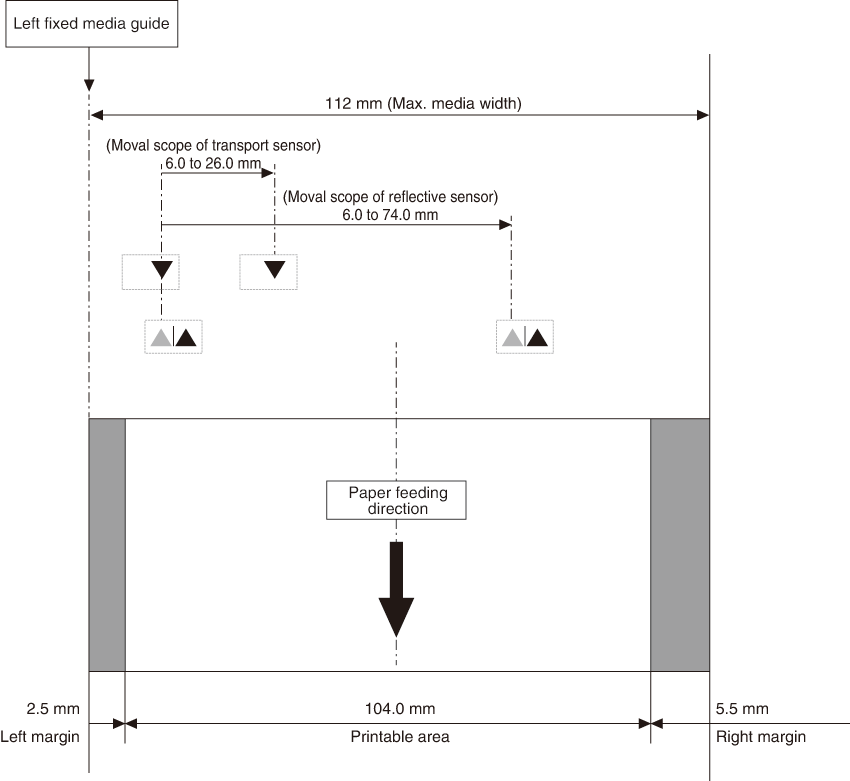

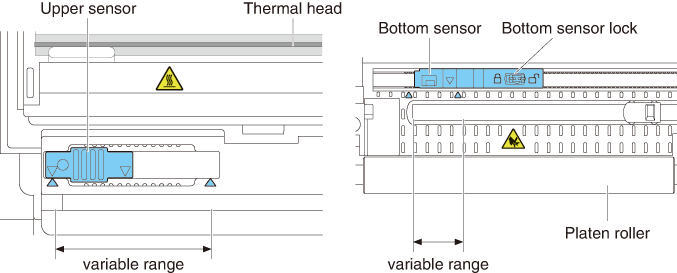

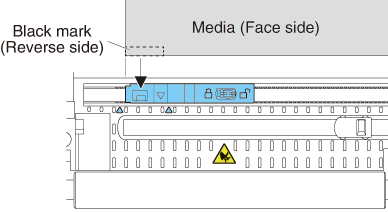

Adjusting Media Sensor Positions

This section describes the procedure to adjust sensors when loading media. Transmissive

and reflective sensors can be used for the media sensors.

Range of Paper Sensor Adjustment

The following figure illustrates the range of media sensor adjustment.

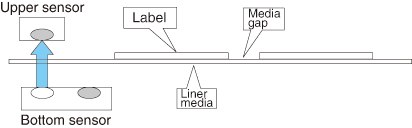

Transmissive Sensor Adjustment

- ●Adjust the position of the bottom sensor and upper sensor in accordance with the media

width.

- Move the bottom sensor and upper sensor by the same number of steps from the position

of the triangle (▲).

- The range of bottom sensor and upper sensor horizontal adjustment is 10 steps between

the triangle marks (▲).

- Use a pen or other object with a narrow tip to unlock the bottom sensor and then reposition

it.

Lock the sensor in place once the new position has been determined.

CAUTION

- The bottom sensor and upper sensor must be in alignment with each other.

- Attempting to move the sensor while still locked may damage it.

Reflective Sensor Adjustment

- ●Set the bottom sensor at a position where the center of the sensor window is in alignment

with the center of the black mark.

Selecting a Paper Type

Paper type selection is available by the combination of memory switches MSW4-4 and

MSW4-5 by the used of “Memory Switch Select Mode”. In addtion, the following procedure

is available.

- 1.Enter Selecting Paper Type mode.

- 1) With the top cover open, turn on the printer power switch while pressing and holding

the FEED key.

The buzzer sounds and the status LED flashes in green.

- 2) Remove your finger from the FEED key briefly, and then press the FEED key three times in succession.

Next, closing the top cover causes the buzzer to sound briefly three times. The type

of paper currently selected is represented by the status display LEDs.

- 2.Select Paper Type.

- Press the FEED key to match the paper used with the paper type displayed by the status display LED.

- (Refer to the table below.)

| Paper |

Status LED |

| Label media |

Green |

| Press the FEED key ↓ |

| Thermal roll paper |

Amber |

| Press the FEED key ↓ |

| Black mark paper |

Red |

| Returns to label paper selection. |

- 3.Save the selected Paper Type to the Printer.

- Open the top cover and then close it as it is.

The paper type selected is stored in the printer memory switch as shown in the table

below. The paper type setting mode finishes and the printer restarts automatically.

| Paper type |

MSW |

| 4-4 |

4-5 |

| Thermal roll paper |

Thermal roll paper |

- |

| Black mark paper |

Black mark paper/label media |

Black mark detection |

| Label media |

Black mark paper/label media |

Label gap detection |

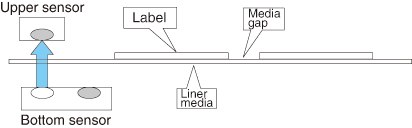

Calibrating the Paper Sensor

Calibrate the paper sensor to suit the actual paper you are using before using label

paper or black mark paper.

Before executing this mode, use the paper selection mode or the MSW-4 and MSW4-5 settings

to set the paper type you want to use.

- 1.Enter Adjusting Paper Sensor mode.

- 1) With the top cover open, turn on the printer power switch while pressing and holding

the FEED key.

The buzzer sounds and the status LED flashes in green.

- 2) Remove your finger from the FEED key briefly, and then press the FEED key four times in succession.

Next, closing the top cover causes the buzzer to sound briefly four times.

- 2.Set Paper to be adjusted to the Printer.

- Setting transmissive sensor positions and media

- 1.Align the bottom sensor and upper sensor with each other at the same position.

- 2.Peel a label and set the media so that only the backing paper (glassine paper) reaches

the platen roller and media sensor.

- Set media with black marks so that a black mark does not cover the media sensor.

- 3.In this status, close the top cover.

- Setting reflective sensor positions and media

- 1.Adjust the bottom sensor so that it is underneath the paper.

- 2.Set the media so that the media covers the platen roller and media sensor.

- Set the media so that a section without a black mark covers the platen roller and

media sensor.

- 3.In this status, close the top cover.

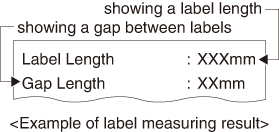

- 3.Adjust media sensor sensitivity and measure the paper length.

- If you press the FEED key, the buzzer sounds once for a short time, the label is fed, and media sensor

sensitivity adjustment and paper length measurement are performed automatically regardless

of the setting of MSW4-1.

The buzzer sounds once for a long time after length measurement and then the printer

restarts automatically.

The length measurement result is saved to the printer and retained in memory even

if the power of the printer is turned off. The length measurement result is printed

in a test print.

If the media sensor sensitivity adjustment or paper length measurement fails, the

buzzer sounds and a black mark / label gaps detection error occurs.

To resolve the error, you need to turn off the power of the printer, load the media

that is currently set, and start the media sensor adjustment mode again.

Precautions for Creating Applications and Practical Operations

If printing is done immediately after the paper is partially cut and torn off, the

top of the next print out may be distorted.

For printing after cutting, we recommend to print with the first line empty.

If you are using a serial interface that has a slow data transmission speed, streaks

may appear in the printouts when you are printing graphics or gradated text, which

require large amounts of data.

USB interfaces may be susceptible to the effects of electromagnetic interference from

the host or environment.

If this is the case, try using a cable with ferrite cores on both ends, which are

very effective at eliminating EMI.

Download Site for Various Electronic Files

You can view support information and download the latest documents, drivers, utilities,

etc. from the following site.

Periodic Cleaning

Printing may not be performed normally if the thermal head, paper feed roller (platen

roller), or sensor protection sheet are dirty, so cleaning should be performed regularly

(every two or three months).

- 1.Turn off the power.

- 2.While pressing the cover release buttons on both sides, open the top cover.

- 3.If immediately after printing, leave the printer for several minutes until the thermal

head cools down.

- 4.Use a cotton swab dipped in ethyl alcohol to wipe the heating surfaces and paper feed

rollers of the thermal heads clean of paper dust, etc.

- 1.Thermal head

- 2.Paper feed roller (platen)

CAUTION

- The thermal head is hot immediately after printing. Be careful not to touch it with

your hands.

- Do not touch the heating surfaces of the thermal head with bare hands or allow metals

to come into contact with it.

Clearing a Cutter Error

If the auto cutter stops during the auto cutter operation with the blade of the auto

cutter in the open position due to foreign matter entering, paper jamming, etc., the

Status LED flashes. When a cutter error occurs, resolve the cutter error with the

following procedure.

- 1.Turn on the power.

- 2.While pressing the cover release button, open the top cover.

- 3.Remove any jammed paper including any scraps of paper. (Remove the paper roll that

is loaded in the holder also.)

- 4.Reload the paper roll and close the paper cover.

CAUTION

- When opening the paper cover, be careful not to touch the entrance of the blade of

the auto cutter.

- The print head is very hot immediately after printing. Be careful not to touch it

with your hands.

- Do not touch the print head with bare hands or metal objects.

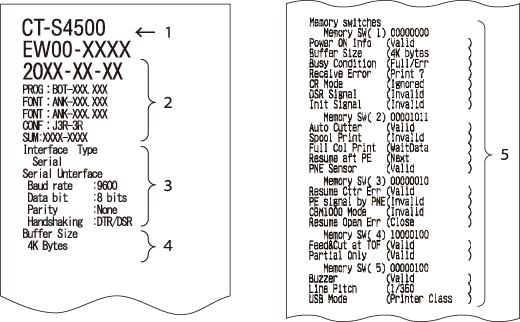

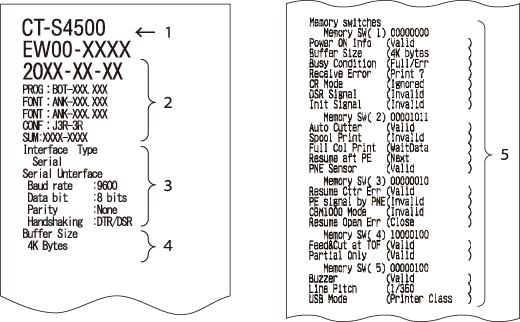

Self Test

You can use self test to check for printer problems.

Performing a self test operation

- 1.While paper is loaded, press and hold the FEED button and turn on the power.

- 2.Hold the FEED button down for about one second until the buzzer sounds. Release the button to start

self test. The printer will print its model name, version, memory switch settings,

and built-in fonts.

- 1.Printer type name

- 2.Firmware version

- 3.Interface settings

- 4.Buffer size

- 5.Memory switch settings

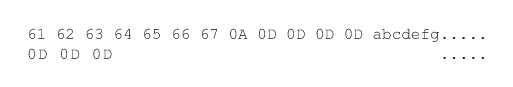

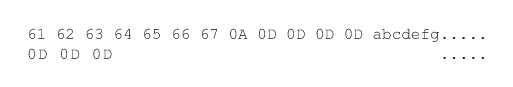

Hexadecimal Dump Printing

Print received data in hexadecimal. If problems such as missing or duplicated data

occur, this function allows you to check whether or not the printer is receiving data

correctly.

How to do hexadecimal dump printing

- 1.Load paper.

- 2.With the top cover open, turn on the printer power while pressing and holding the

FEED key, and then close the top cover.

- 3.The printer will print “HEX dump print mode” followed by the received data printed

in hexadecimal numbers and some characters.

How to stop hexadecimal dump printing

Do one of the following to stop printing.

- Press the FEED button consecutively three times

- Turn off the power

- Receive a reset command from an interface

CAUTION

- The printer prints “.” if there is no character corresponding to the data.

- None of the commands function during hexadecimal dump printing.

- If print data does not cover a complete line, press the FEED button to advance the paper.

Print example

HEX dump print mode

Error Indications

- Paper end, paper near-end

The end of paper is detected in two stages, paper near-end and paper end.

For paper near-end, the status LED lights amber. Prepare to replace the paper.

For paper end, the status LED lights red and the buzzer sounds. Load a new paper roll.

The buzzer may not sound depending on the memory switch setting.

- Cover open

If the cover is opened, the status LED lights red.

The buzzer may sound depending on the memory switch setting.

Do not open the cover during printing. If the cover is accidentally opened, the status

LED flashes in red and the buzzer sounds. Check the paper, pull it straight out of

the printer by a couple of centimeters, and then close the cover. Printing restarts.

A command must be sent to restart printing depending on the memory switch setting.

- Cutter error

If the auto cutter stops due to paper jamming, etc., the status LED flashes in red

and the buzzer sounds. Remove the cause and press the FEED key. If the auto cutter still does not move and the paper cover cannot be opened,

refer to “Clearing a Cutter Error.”

- Print Head Hot

Dense printing, heavy black printing, and continuous printing in a high temperature

environment increase the temperature of the print head. When the print head exceeds

a certain temperature, the printer stops printing and waits until the temperature

of the print head decreases. At this time, the status LED flashes in red. When the

temperature decreases, printing restarts automatically.

The status display for various messages is shown below.

| Status |

Color |

Status LED |

Buzzer*1 |

| Paper near-end |

Amber |

Lit |

No |

| Paper-end |

Red |

Lit |

Yes*2 |

| Cover open*3 |

Red |

Lit |

No*2 |

| Cover open II*4 |

Red |

|

No*2 |

| Cutter locked |

Red |

|

Yes |

| Low-voltage error |

Red |

|

No |

| High-voltage error |

Red |

|

No |

| System error |

Red |

|

No |

| Memory error |

Red |

|

No |

| Print head hot |

Amber |

|

No |

Black mark/

label gaps detection error |

Red |

|

Yes |

| Wait for Macro Execution |

Amber |

|

No |

Notes:

*1: Buzzer sounds when MSW5-1 (buzzer setting) is set to ON.

*2: The buzzer can be set to sound or not sound with MSW10-5 (buzzer event).

*3: Indicated when a cover is opened during standby.

*4: Indicated when a cover is opened during standby.

Paper Jams

Take care to avoid obstruction of the paper outlet and paper jamming around the outlet

during printing.

If paper cannot get out of the printer, it can roll up on the platen inside the printer

and cause an error.

If the paper wraps around the platen, open the paper cover and carefully pull the

paper out.

Precautions for Performing Printing for Which Printing Speed Changes

When printing for which the printing speed changes is performed, white lines may be

printed or paper may not be fed depending on the printing conditions. To prevent these

problems, change the following memory switch settings.

- 1.Enable MSW2-3 (buffering).

- 2.Increase the baud rate of MSW7-1 (serial baud rate).

- 3.Change MSW10-2 (print speed) to a lower level.

CAUTION

- Depending on the serial interface transmission speed, ambient temperature, print data

duty, and other factors, changing the above settings may not eliminate the problems.

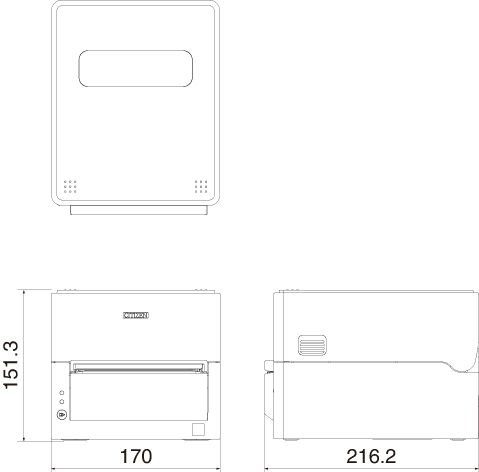

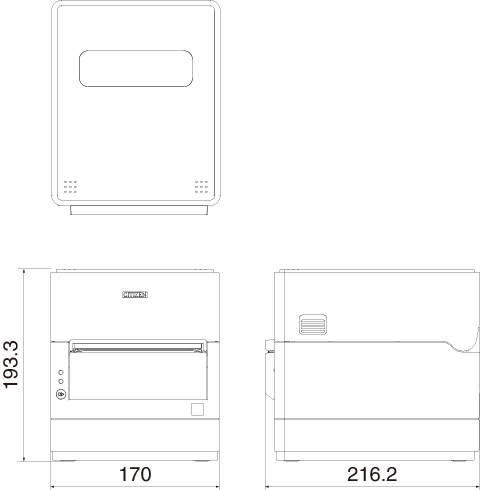

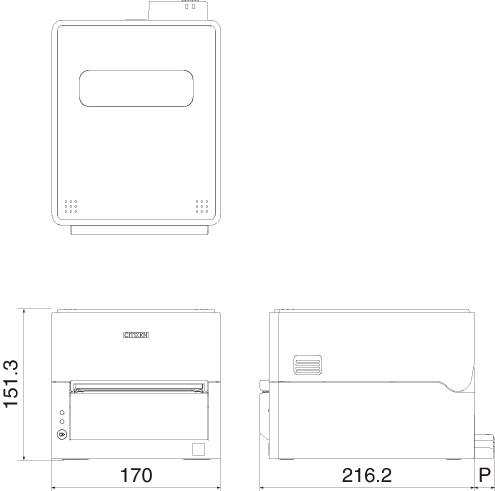

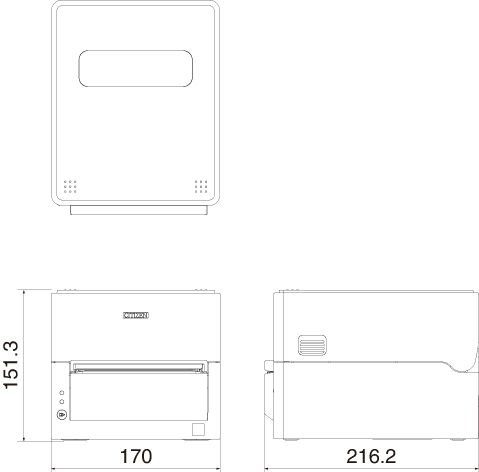

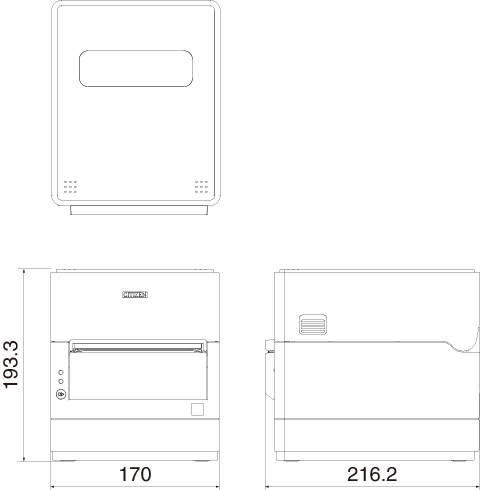

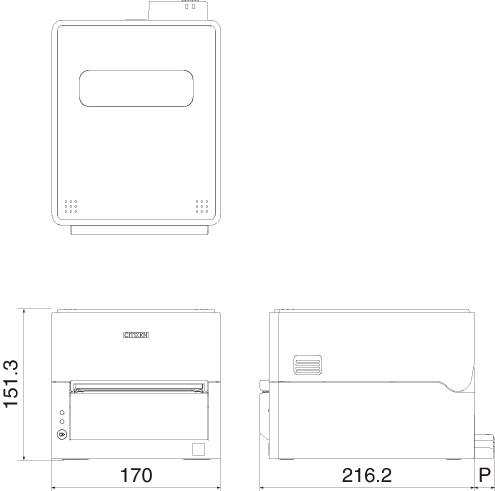

External Views and Dimensions

(Unit: mm)

Standard model

Standard AC adapter-equipped model

Optional interface-equipped model

Protrusion amount at back of optional interface (P)

Serial RS-232C: 1.5 mm

Ethernet, Ethernet USB host, and wireless LAN: 20 mm

Bluetooth and Bluetooth + USB host: 19 mm

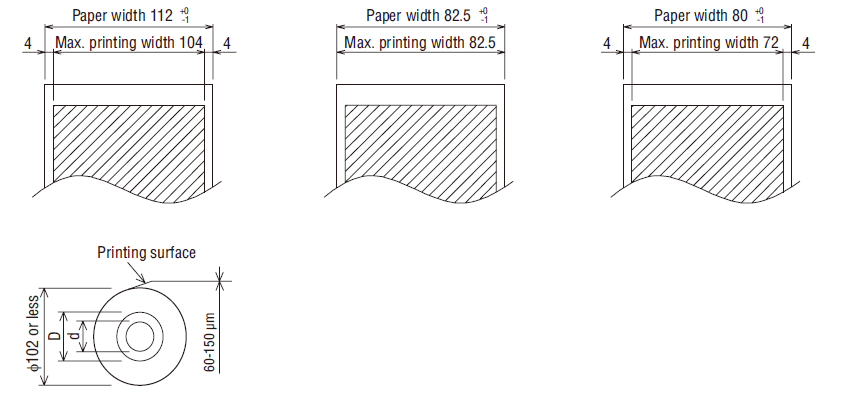

Printing Paper

Use the paper shown in the following table or paper of the same quality.

| Paper type |

Product name |

| Recommended thermal roll paper |

Nippon Paper TF50KS-E, TF50KS-E2D

Oji Paper PD150R, PD160R

Mitsubishi Paper Mills P220AE-1

|

| Recommended thermal label roll paper |

Nippon Paper HD75

Ricoh 150LA-1P-ST

|

(Unit: mm)

| Paper thickness (μm) |

60 to 85 |

85 to 150 |

| Core inner diameter d (mm) |

ø12 to ø25.4 |

ø25.4 |

| Core outer diameter D (mm) |

ø18 to ø32 |

ø32 |

CAUTION

- Use thermal paper that is wound as follows:

- Not creased and fits tight to the core.

- Not folded.

- Not glued to the core.

- Rolled with the printable side out.

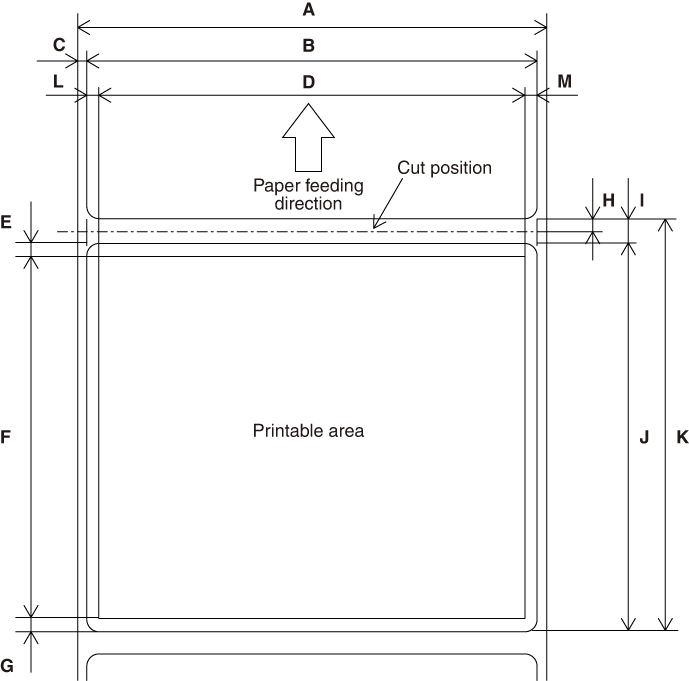

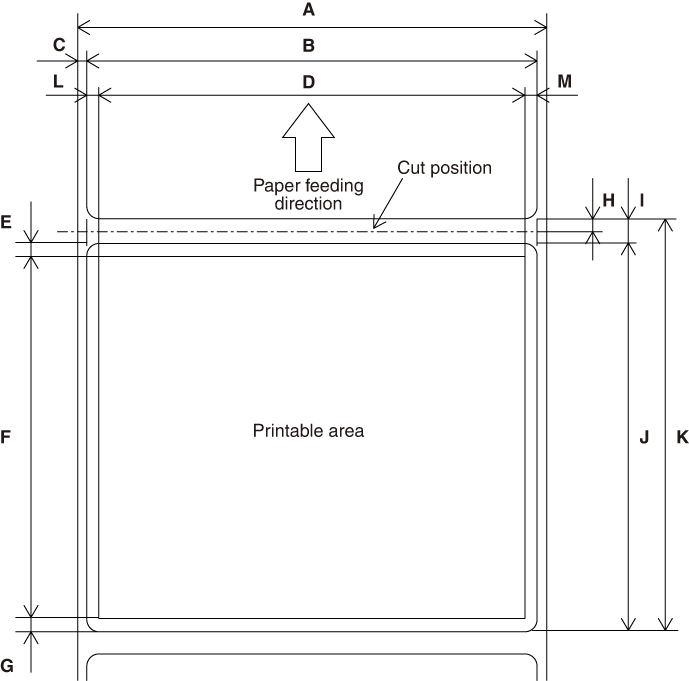

(Unit: mm)

| Mark |

Item |

Dimensions |

| A |

Label backing width |

58 to 112 0/-1 |

| B |

Label width |

54 to 108±0.5 |

| C |

Left edge of label |

2±0.5 |

| D |

Print width |

45 to 104 |

| E |

Top margin |

2+2/-2 |

| F |

Print length |

21 to 296 |

| G |

Bottom margin |

2+2/-2 |

| H |

Cut position between labels |

2 or more |

| I |

Gap between labels |

4 to 30 |

| J |

Label length |

25 to 300 |

| K |

Label pitch |

I+J |

| L |

Left margin |

2±1 |

| M |

Right margin |

2±1 |

CAUTION

- Make sure the cut position is between labels.

Cut the backing paper. Do not cut label paper (tack paper).

- Always re-calibrate the paper sensor whenever you change the label backing paper type.

- Do not use full-surface label media.

- Rolled with the printable side out.

- For roll paper end processing, do not glue the roll paper to the core.

Also, do not fold the end.

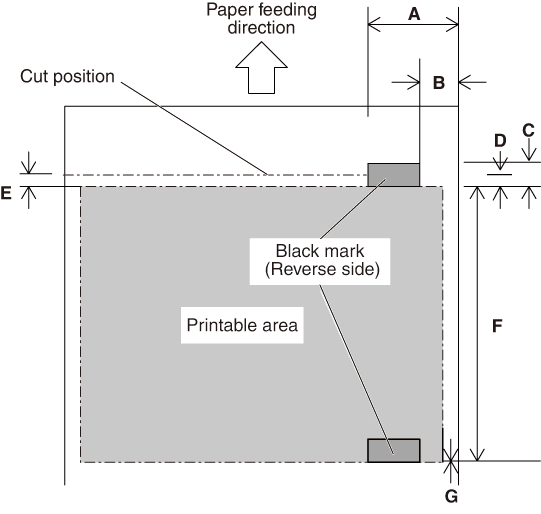

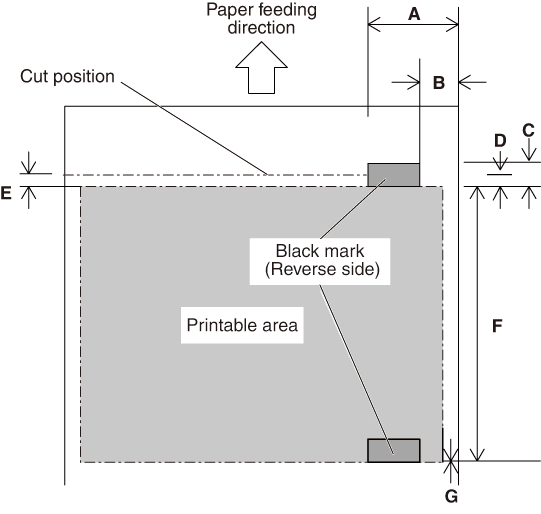

(Unit: mm)

| Mark |

Item |

Dimensions |

| Minimum |

Maximum |

| A |

Left edge of black mark |

15 |

66.5 |

| B |

Right edge of black mark |

0 |

51.5 |

| A-B |

Black mark width |

15 |

- |

| C |

Black mark height |

4 |

17.8 |

| D |

Cut position in black mark |

Center in height direction ±2 |

| E |

Top margin |

2+2/-2 |

| F |

Black mark pitch |

30 to 300 |

| G |

Bottom margin |

0±1 |

CAUTION

- The black mark PCS value should be at least 0.90.

- Concerning the accuracy of feeding with black mark detection, allow for an error of

±2 mm from the reference print position, or for a maximum error of -5% from the value

set for the print length.

- The print area is as shown in the illustration above when black marks are being used.

Make sure to allow for adequate margins.

The printer will perform a page skip operation if the print data runs outside of the

print area.

- When pre-printing on black mark paper, print outside of the area detected by the black

mark sensor.

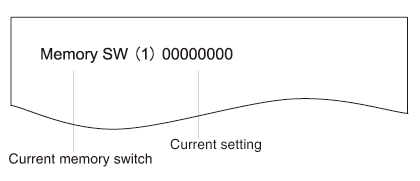

Manual Setting of Memory Switches

Memory switches are used to set various printer settings. Memory switches can be set

manually, or by utilities or commands. This section explains how to perform manual

settings.

For information on how to set the memory switches using commands, please refer to

the Command Reference.

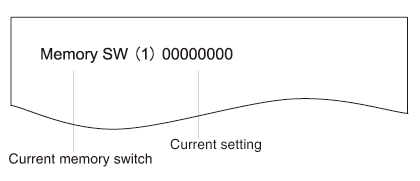

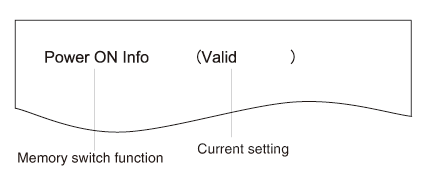

Individual setting mode

Set the memory switches individually.

Do the settings while confirming the memory switch function and settings on the printout.

- 1.Load paper.

- 2.With the top cover open, turn on the printer power while pressing and holding the

FEED key.

- 3.Press the FEED button twice and close the paper cover.

- The printer enters the mode for setting memory switches individually.

- The printer prints “Memory SW (1)” and the current setting, 0 (off) or 1 (on).

- (The current settings for memory switches 7 to 13 are not printed.)

- 4.Press the FEED button.

- Each press of the FEED button cycles through the list of memory switches in the following sequence: “Memory

SW (1)” > “Memory SW (2)” > ...“Memory SW (11)” or “Memory SW (13)” > “Save To Memory”

> “Memory SW (1)”.

- Press the FEED button until the number for the memory switch you want to change is printed.

- 5.Press the FEED button for at least two seconds.

- A setting for the memory switch is printed, through the cycle, each time the FEED button is pressed for at least two seconds.

- Press the FEED button for at least two seconds to cycle through the list until the function of the

memory switch you want to change is printed.

- 6.Press the FEED button.

- A setting is printed each time the FEED button is pressed in order through the cycle.

- When the current settings are printed, the COVER LED lights.

- Press the FEED button until the setting you want is printed.

- 7.Press the FEED button for at least two seconds.

- The selected settings are set.

- The next memory switch function and settings are printed.

- 8.Repeat steps 5 to 7 to change different functions for the current memory switch number.

- 9.Open the paper cover and close it.

- The changed memory switch settings are printed.

- 10.Repeat steps 4 to 9 to change functions for a different memory switch number.

- 11.Press the FEED button until “Save To Memory” is printed.

- 12.Press the FEED button for at least two seconds.

- The changed memory switch settings are saved and a list of them is printed.

- The printer exits individual setting mode when printing is finished.

Memory switch initialization

Set all the memory switches to the factory settings.

- 1.Do steps 1 through 3 of the procedure to enter individual setting mode.

- 2.Press the FEED button until “Save To Memory” is printed.

- 3.Open the paper cover.

- 4.Press the FEED button for at least two seconds.

- All memory switches change to the factory settings.

- 5.Close the paper cover.

The function of each memory switch is shown in the following table. (Shaded values

are factory settings.)

| Switch no. |

Function |

OFF |

ON |

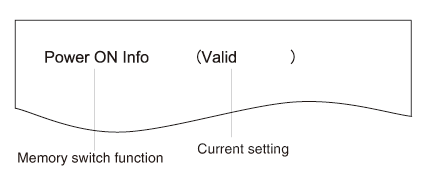

| MSW1-1 |

Power ON Info |

Valid |

Not Send |

| MSW1-2 |

Buffer Size |

4 Kbytes |

45 bytes |

| MSW1-3 |

Busy Condition |

Full/Err |

Full |

| MSW1-4 |

Receive Error |

Print“?” |

No Print |

| MSW1-5 |

CR Mode |

Ignored |

LF |

| MSW1-6 |

Reserved |

Fixed |

— |

| MSW1-7 |

DSR Signal |

Invalid |

Valid |

| MSW1-8 |

INIT Signal |

Invalid |

Valid |

|

|

|

|

| MSW2-1 |

Reserved |

— |

Fixed |

| MSW2-2 |

Auto Cutter |

Invalid |

Valid |

| MSW2-3 |

Spool Print |

Invalid |

Valid |

| MSW2-4 |

Full Col Print |

LineFeed |

WaitData |

| MSW2-5 |

Resume aft PE |

Next |

Top |

| MSW2-6 |

Reserved |

Fixed |

— |

| MSW2-7 |

Reserved |

Fixed |

— |

| MSW2-8 |

PNE Sensor |

Valid |

Invalid |

|

|

|

|

| MSW3-1 |

Resume Cttr Err |

Valid |

Invalid |

| MSW3-2 |

PE signal by PNE |

Valid |

Invalid |

| MSW3-3 |

Reserved |

Fixed |

— |

| MSW3-4 |

Reserved |

Fixed |

— |

| MSW3-5 |

Reserved |

Fixed |

— |

| MSW3-6 |

Reserved |

Fixed |

— |

| MSW3-7 |

CBM1000 Mode |

Invalid |

Valid |

| MSW3-8 |

Resume Open Err |

Close |

Command |

|

|

|

|

| *1MSW4-1 |

P.Length |

Auto Measure |

Command |

| *1MSW4-2 |

Power on TOF |

Invalid |

Valid |

| *1*2MSW4-3 |

Feed&Cut at TOF |

Invalid |

Valid |

| MSW4-4 |

Paper Select |

Thermal Roll |

BM.P/Lbl.P |

| MSW4-5 |

Position detect |

Black mark |

Label |

| MSW4-6 |

Measure at Close |

Invalid |

Valid |

| MSW4-7 |

Reserved |

Fixed |

— |

| *3NSW4-8 |

Partial Only |

Invalid |

Valid |

|

|

|

|

| MSW5-1 |

Buzzer |

Valid |

Invalid |

| MSW5-2 |

Line Pitch |

1/360 |

1/406 |

| MSW5-3 |

USB Mode |

Virtual COM |

Printer Class |

| MSW5-4 |

Reserved |

Fixed |

— |

| MSW5-5 |

Reserved |

Fixed |

— |

| MSW5-6 |

Reserved |

Fixed |

— |

| MSW5-7 |

Reserved |

Fixed |

— |

| MSW5-8 |

Reserved |

Fixed |

— |

|

|

|

|

| MSW6-1 |

Act. For Driver |

Invalid |

Valid |

| MSW6-2 |

Character Space |

Invalid |

Valid |

| MSW6-3 |

USB Power Save |

Invalid |