LINE THERMAL PRINTER

MODEL CL-E321/CL-E331

User’s Manual

WEEE MARK

|

If you want to dispose of this product, do not mix it with general household waste.

There is a separate collection systems for used electronics products in accordance

with legislation under the WEEE Directive and is effective only within European Union.

|

|

Wenn Sie dieses Produkt entsorgen wollen, dann tun Sie dies bitte nicht zusammen mit

dem Haushaltsmüll. Es gibt im Rahmen der WEEE-Direktive innerhalb der Europäischen

Union gesetzliche Bestimmungen für separate Sammelsysteme für gebrauchte elektronische

Geräte und Produkte.

|

|

Si vous souhaitez vous débarrasser de cet appareil, ne le mettez pas à la poubelle

avec vos ordures ménagères. Il existe un système de récupération distinct pour les

vieux appareils électroniques conformément à la législation WEEE sur le recyclage

des déchets des équipements électriques et électroniques qui est uniquement valable

dans les pays de l’Union européenne.

Les appareils et les machines électriques et électroniques contiennent souvent des

matières dangereuses pour l’homme et l’environnement si vous les utilisez et vous

vous en débarrassez de façon inappropriée.

|

|

Si desea deshacerse de este producto, no lo mezcle con residuos domésticos de carácter

general. Existe un sistema de recogida selectiva de aparatos electrónicos usados,

según establece la legislación prevista por la sobre residuos de aparatos eléctricos

y electrónicos (RAEE), vigente únicamente en la Unión Europea.

|

|

Se desiderate gettare via questo prodotto, non mescolatelo ai rifiuti generici di

casa. Esiste un sistema di raccolta separato per i prodotti elettronici usati in conformità

alla legislazione RAEE, valida solo all’interno dell’Unione Europea.

|

|

Deponeer dit product niet bij het gewone huishoudelijk afval wanneer u het wilt verwijderen.

Er bestaat ingevolge de WEEE-richtlijn een speciaal wettelijk voorgeschreven verzamelsysteem

voor gebruikte elektronische producten, welk alleen geldt binnen de Europese Unie.

|

|

Hvis du vil skille dig af med dette produkt, må du ikke smide det ud sammen med dit

almindelige husholdningsaffald. Der findes et separat indsamlingssystem for udtjente

elektroniske produkter i overensstemmelse med lovgivningen under WEEE-direktivet,

som kun er gældende i den Europæiske Union.

|

|

Se quiser deitar fora este produto, não o misture com o lixo comum. De acordo com

a legislação que decorre da Directiva REEE – Resíduos de Equipamentos Eléctricos e

Electrónicos, existe um sistema de recolha separado para os equipamentos electrónicos

fora de uso, em vigor apenas na União Europeia.

|

|

Jeżeli zamierzasz pozbyć się tego produktu, nie wyrzucaj go razem ze zwykłymi domowymi

odpadkami. Według dyrektywy WEEE obowiązującej w Unii Europejskiej dla używanych produktów

elektronicznych należy stosować oddzielne sposoby utylizacji.

|

Compliance Statement for European Users

|

FCC Compliance Statement for American Users

FCC Related Information

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Pursuant to FCC regulations, you are cautioned that any changes or modifications not

expressly approved in this manual could void your authority to operate this equipment.

|

|

Sicherheitshinweis

Die Steckdose zum Anschluß dieses Druckers muß nahe dem Gerät angebracht und leicht

zugänglich sein.

|

|

EMI Compliance Statement for Canadian Users

This Class B Information Technology Equipment (ITE) complies with Canadian CAN ICES-3(B)/NMB-3(B).

This equipment generates and uses radio frequency energy and if not installed and

used properly, that is, in strict accordance with the manufacturer’s instructions,

may cause interference to radio and television reception. This Information Technology

Equipment (ITE) does not exceed the Class B limits for radio noise emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications. This equipment is designed

to provide reasonable protection against such interference in a residential installation.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

État de conformité EMI à l’usage des utilisateurs Canadiens

Cet Équipements informatiques (EI) de la classe B est conforme à la norme CAN ICES-3(B)/NMB-3(B) du Canada.

Cet équipment produit et utilise l’énergie à radiofréquences et s’iln’est pas installé

et utilisé correctment, c’esst à dire en accord strict avec les instructions du fabricant,

il risque de provoquer des intérferences avec la réception de la radio et de latélévision.

Le présent Équipements informatiques (EI) n’émet pas de bruite radio électriques dépassant

les limites applicables aux appareils numériques de la classe B prescrites dans le Réglement sur le brouillage radioélectrique édicté par le ministère

des Communications du Canada.

Cet équipment est conçu pour fournir une protection satisfaisante contre de telles

interférences dans une installation résidentielle.

Cependant, il n’y a pas de garantie contre les interférences avec les réceptions radio

ou télévision, provoquées par la mise en et hors circuit de l’équipment; aussi, il

est demandé a l’utilisateur d’essayer de corriger l’interférence par l’une ou plus

des mesures suivantes:

- Réorienter l’antenne de réception.

- Installer l’ordinateur autre part, par égard pour le récepteur.

- Brancher l’ordinateur dans une prise de courant différente de façon à ce que l’ordinateur

et le récepteur soient branchés sur des circuits différents.

- Consulter le revendeur ou un technicien radio/ TV expérimenté pour toute assistance.

|

GENERAL PRECAUTIONS

- Before using this product, be sure to read through this manual. After having read

this manual, keep it in a safe, readily accessible place for future reference.

- The information contained herein is subject to change without prior notice.

- Reproduction or transfer of part or all of this document in any means is prohibited

without permission from Citizen Systems.

- Note that Citizen Systems is not responsible for any operation results regardless

of omissions, errors, or misprints in this manual.

- Note that Citizen Systems is not responsible for any trouble caused as a result of

using options or consumables that are not specified in this manual.

- Except explained elsewhere in this manual, do not attempt to service, disassemble,

or repair this product.

- Citizen Systems Japan Co., Ltd. shall not be liable for damages caused by improper

or incorrect usage or by the usage environment.

- Data is basically for temporary use and not stored for an extended period of time

or permanently. Please note that Citizen Systems is not responsible for damage or

lost profit resulting from the loss of data caused by accidents, repairs, tests or

other occurrences.

- If you find omissions, errors, or have questions, please contact your Citizen Systems

dealer.

|

- CITIZEN is a registered trademark of Citizen Watch Co., Ltd.

- QR Code is a registered trademark of DENSO WAVE INCORPORATED.

- Datamax® is a registered trademark of Datamax-O'Neil Inc.

- Maxi Code is a registered trademark of UPS.

- Zebra®, Eltron®, ZPL2™, and EPL2™ are registered trademarks of ZIH Corp., USA

- PDF417 is a trademark or registered trademark of Motorola, Inc. in the U.S. and other

countries.

- TrueType™ is a trademark of Apple Inc.

- All other trademarks are the property of their respective owners.

- Citizen Systems use these trademarks in accordance with the license of relevant owners.

Copyright© CITIZEN SYSTEMS JAPAN CO., LTD. 2019

SAFETY PRECAUTIONS...WHICH SHOULD BE STRICTLY OBSERVED

Before using this product for the first time, carefully read these SAFETY PRECAUTIONS.

Improper handling may result in accidents (fire, electric shock or injury).

In order to prevent injury to operators, third parties, or damage to property, special

warning symbols are used in the User’s Manual to indicate important items to be strictly

observed.

- After having read this Manual, keep it in a safe, readily accessible place for future reference.

- Some of the descriptions contained in this manual may not be relevant to some printer

models.

The following describes the degree of hazard and damage that could occur if the printer

is improperly operated by ignoring the instructions indicated by the warning symbols.

Be sure to read this information carefully.

WARNING

- Neglecting precautions indicated by this symbol may result in fatal or serious injury.

|

CAUTION

- Neglecting precautions indicated by this symbol may result in injury or damage to

property.

|

|

This symbol is used to alert your attention to important items. |

Warnings

WARNING

|

- Do not perform any of the following actions as they may result in damage or malfunction

of the device, overheating, the generation of smoke, fire, or electric shock. If the

device is damaged or defective, turn off the power, disconnect the power plug from

the electrical outlet, and contact your retailer.

- Do not step on, drop, hit, or otherwise subject the device to significant force or

impact.

- Do not use the device in environments of poor ventilation or in a manner that blocks

device vents.

- Do not use the device in environments, such as laboratories, where chemical reactions

occur or environments exposed to air that contains salt or toxic gases.

- Use the device in environments at specified power supply voltage and frequency (100

to 240 V and 50/60 Hz).

- Do not connect or disconnect the power cord or an interface cable by holding the cable

itself. Do not pull or carry the device while cables are under load.

- Do not drop or insert small objects such as clips or push-pins into the device.

- Do not connect too many power cords to a single electrical outlet.

- Do not spill tea, coffee, juice, or other beverages onto the device. Do not subject

the device to insecticides. If liquid is spilled onto the device, turn off the power,

disconnect the power plug from the electrical outlet, and contact your retailer.

- Do not disassemble or modify the device.

- Do not use non-specified AC adapters.

- Use only the included power cord. Do not use the included power cord with other devices.

- Do not use deformed or damaged power cords.

- Do not unnecessary process power cords.

- Do not print while the top ribbon cover is open. An injury may occur due to hair or

clothing being caught in the ribbon.

- Exposed wire due to damaged power cords or melted sheaths may cause current leakage,

malfunction, or electric shock. Contact your retailer if the power cord becomes damaged.

- Do not place objects around the power plug.

|

|

PRECAUTIONS IN HANDLING THE PRINTER

CAUTION

|

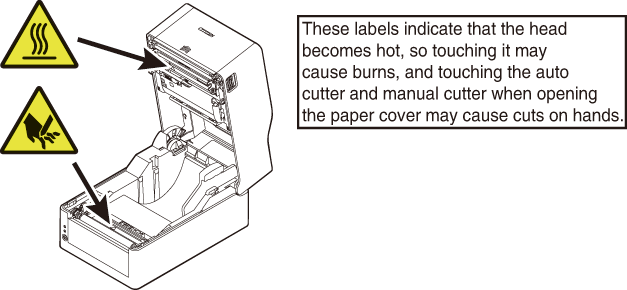

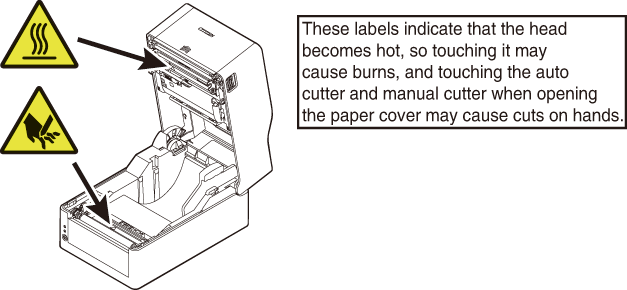

- Caution label is attached in the position shown in the following figure. Carefully

read the handling precautions before using the printer.

|

CAUTION

|

- Do not touch the area around the thermal head during or right after the printing process.

This area will be hot and may cause burns.

- Do not drop or insert small objects such as clips or pins into the printer. Doing

so may result in failure.

- Exercise caution when carrying or transporting the device. Dropping the device may

damage other objects or cause injury.

- Make sure to open the printer cover fully when it needs to be opened. Failure to do

so may result in the printer closing unexpectedly, which may cause injury.

- Exercise caution when the printer cover is open. Contact with edges may result in

injury.

- Do not open the printer cover while the printer is printing.

- Do not print while the top ribbon cover is open. A failure may occur if the ribbon

is touched or a foreign object is dropped on it.

- Do not use thinner, trichlene, benzene, ketone-based solvents, or cleaning cloths

with chemicals to clean the case surface.

- Do not use the device in environments exposed to significant levels of oil, metal

shavings, waste, and dust.

- Do not spill liquids onto the device or expose the device to spray chemicals.

- Do not step on, drop, hit, or otherwise subject the device to significant force or

impact.

- Make sure to use the control panel correctly. Pressing buttons randomly may cause

malfunction and even failure. Do not use sharp objects including tips of pens to operate

the control panel.

- If some abnormality occurs during use, immediately stop using the device and disconnect

the power plug from the electrical outlet.

- Do not disassemble the device for repairs in case of failure. Always contact the dealer

for repairs.

- The auto cutter has internal blades near the media discharge port. Never insert hands

inside the media discharge port whether the printer is operating or not.

- There is a risk of the thermal head being damaged by static electricity. Take measures

to prevent the charging of static electricity in advance, and do not directly touch

the thermal head heating element and connector terminal parts when handling the printer.

- Clean the platen regularly because printing or cutting at the correct position may

become impossible if it is dirty.

- Paper with perforated lines will make the platen extremely dirty so cleaning when

starting use is recommended.

- Cutting at perforated lines is not recommended because an extremely large amount of

paper dust and paper scraps will be generated.

|

|

PRECAUTIONS ON PRINTER INSTALLATION

CAUTION

|

- Do not use or store the device in environments exposed to excessive heat, moisture,

direct sunlight, near heaters, extremely high or low altitudes, excessive humidity,

or excessive dust.

- Do not use the device in environments, such as laboratories, where chemical reactions

occur.

- Do not use the device in environments exposed to air that contains salt or toxic gases.

- Place printers on level, stable surfaces in environments with good ventilation. (Do

not place the printer such that the vents are against walls.)

- Do not place objects on top of the device.

- Using the device near radios or televisions or plugging the power cord into the same

electrical outlet as used by such devices may cause reception interference.

- Use the device in environments at specified power supply voltage and frequency.

- Use only the included power cord. Do not use the included power cord with other devices.

- Do not place objects or step on power cords.

- Do not pull or attempt to carry the device by the power cord or an interface cable.

- Do not connect too many power cords to a single electrical outlet.

- Do not bundle the power cord.

- Hold the power cord by the power plug to connect and disconnect to/from electrical

outlets.

- Ensure connectors are properly connected. In particular, reversing the polarity may

damage internal parts.

- Turn the power switch off before connecting or disconnecting interface cables.

- Do not run long signal lines or make connections with noisy devices to the extent

possible. If necessary, use shielded twisted pair cables for signal lines and take

any other necessary steps to ensure signal integrity.

- Place the device near an electrical outlet and ensure that the power plug can be unplugged

easily so that the power to the device can be cut quickly if necessary.

- Use electrical outlets with ground terminal screws. Using electrical outlets without

ground terminals may result in injury due to static electricity.

- Do not install the printer in a location where there is vibration or in an unstable

location.

|

|

GENERAL OUTLINE

Thank you for purchasing the Citizen Systems Line Thermal Printer CL-E321 / CL-E331.

This printer is a line thermal printer employing the direct-thermal method and thermal-transfer

method that was developed for labels, tags, tickets, and many other applications.

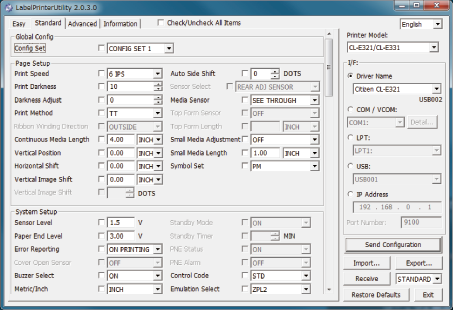

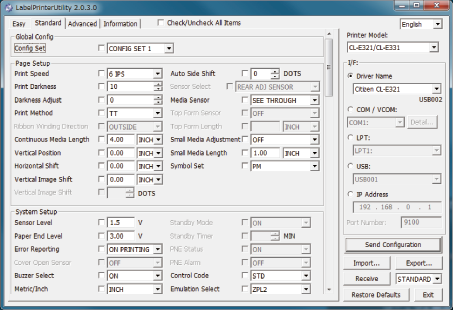

Configuring Printer Settings Using the Specialized Utility

Use the LabelPrinterUtility configuration application to change printer settings.

Refer to the following sections for more information on obtaining and using LabelPrinterUtility.

Configuring Ethernet Network Settings Using Network Seeker

You can check and change the settings of the wired LAN interface board by using CITIZEN

Network Seeker, which is utility software that runs in Windows.

Configuring Printer Settings Using a Browser

Printer and network settings can be configured using a Web browser via the printer’s

built-in LinkServer function.

Clearing Jobs Stored in the Printer

Jobs stored in the printer can be cleared when the printer is paused.

- 1.Press the FEED key if the printer is printing or receiving data.

- The printer is now paused.

- 2.Press and hold the FEED key for at least 3 seconds.

- The buzzer emits 1 short tone.

- 3.Release the FEED key.

- One job has been cleared.

- Alternatively, continue to press and hold the FEED key for at least 3 second without releasing your finger until the buzzer emits 2

short tones.

- 4.Release the FEED key once the buzzer emits 2 short tones.

- All jobs have been cleared.

Maintenance

Perform printer maintenance on a regular basis to ensure that the printer is always

in good working condition.

CAUTION

- Excluding ethyl alcohol, do not use solvents such as benzene, acetone, thinner, or

others to clean the printer. Doing so may cause the printer surface or other parts

to deform.

- CITIZEN is a registered trademark of Citizen Watch Co., Ltd.

- QR Code is a registered trademark of DENSO WAVE INCORPORATED.

- Datamax® is a registered trademark of Datamax-O'Neil Inc.

- Maxi Code is a registered trademark of UPS.

- Zebra®, Eltron®, ZPL2™, and EPL2™ are registered trademarks of ZIH Corp., USA

- PDF417 is a trademark or registered trademark of Motorola, Inc. in the U.S. and other

countries.

- TrueType™ is a trademark of Apple Inc.

- All other trademarks are the property of their respective owners.

- Citizen Systems use these trademarks in accordance with the license of relevant owners.

Copyright© CITIZEN SYSTEMS JAPAN CO., LTD. 2019

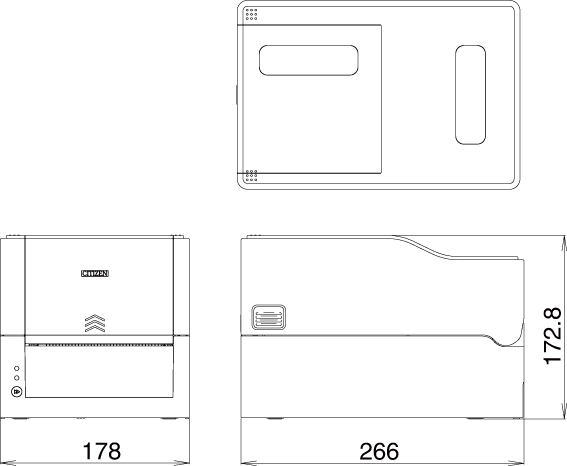

Features

< Compact and Stylish Design >

- Boasting the smallest footprint in the industry, this printer was designed to be compact

to free users from placement restrictions.

- The stylish design enables the device to be used in different environments.

- Exterior color options include black and pure white.

- This printer is compact yet allows you to use a 300 m per roll, large-diameter ink

ribbon.

< High-speed, High-quality Printing >

- This printer employs the direct-thermal method and thermal-transfer method by utilizing

a thermal head, and includes a 32-bit RISC CPU with a maximum operating frequency

of 216 MHz and thermal history control to provide high-speed, high-quality performance

up to 8 IPS with the CL-E321 model and up to 6 IPS with the CL-E331 model.

< Adjustable Sensors Provided as Standard >

- Adjustable media/black line sensors are provided as standard so that the detection

position can be adjustable horizontally. This enables sensors to be placed at detection

positions suitable for different types of media.

< Interface >

- Standard interfaces include a 9-pin, DSUB RS232C interface, full-speed USB 2.0 port,

and an Ethernet port that supports 100BASE-TX and 10BASE-T. These interfaces enable

high-speed connections to many peripheral devices.

< Excellent Usability >

- Manual media cutters are installed at the top and bottom of the media discharge port

to cut media after being printed for better usability in many different environments.

- The operation panel has been designed to have a different color than the main exterior

color for better visibility and stress-free operation.

- Thermal heads and platen rollers can be easily replaced without the use of tools.

< Easy to Use >

- The ribbon loading section has a structure that facilitates easy loading of a ribbon

thanks to the adoption of an up/down opening mechanism.

- Use the LabelPrinterUtility developed by Citizen to configure printer settings from a host computer.

- The built-in LinkServer™ printer tool can be used over Ethernet connections to change

settings and perform other operations.

- The printer includes mechanisms to allow you to easily adjust the head balance and

ribbon left/right balance.

<Models with cutter and models with AC adapter storage case are available>

- Models equipped with an auto cutter are also available.

- Models that allow you to store the AC adapter at the bottom of the printer are also

available.

Model Classification

Model numbers indicate printer features according to the following system.

- 1.Model name

- CL-E321: 203 DPI

- CL-E331: 300 DPI

- 2.Fixed value

- 3.Market

- A: Asia

- C: China

- E: Europe

- U: North America

- 4.Body case color

- B: Black

- W: Pure white

- 5.Interface

- N: USB port, wired LAN, and serial port

- 6.Cutter

- N: None

- BC: Available

- 7.AC adapter storage case

- A: Not available

- S: Available

Certain combinations may not be available. Please contact us for inquiries on desired

configurations.

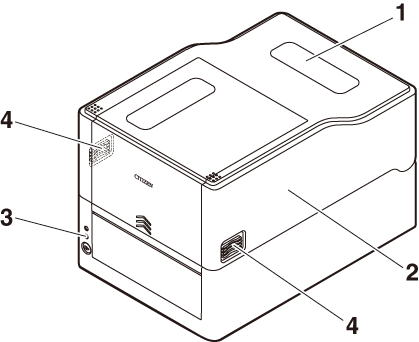

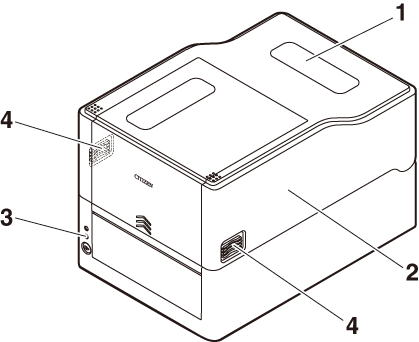

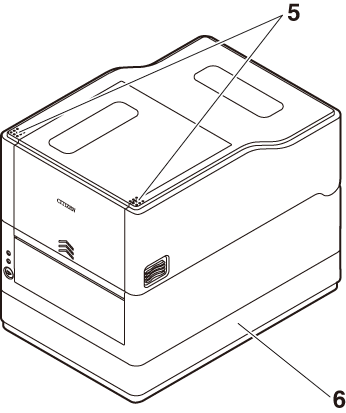

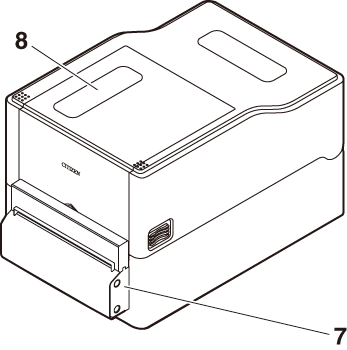

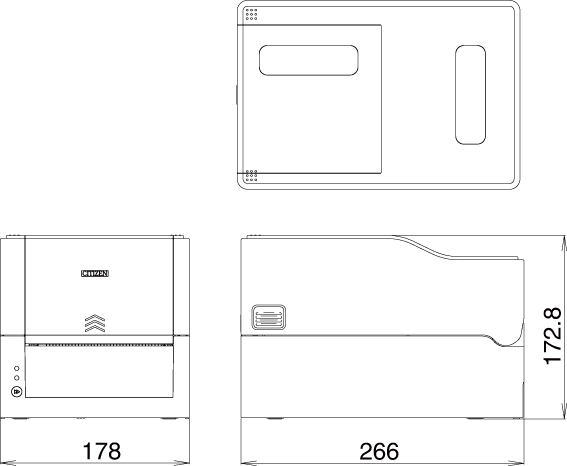

Front of Printer

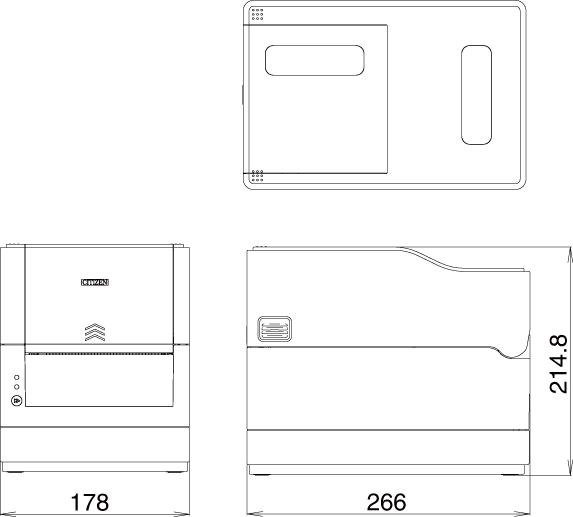

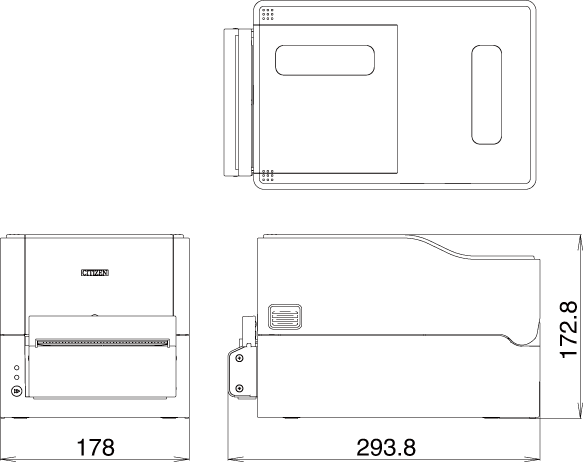

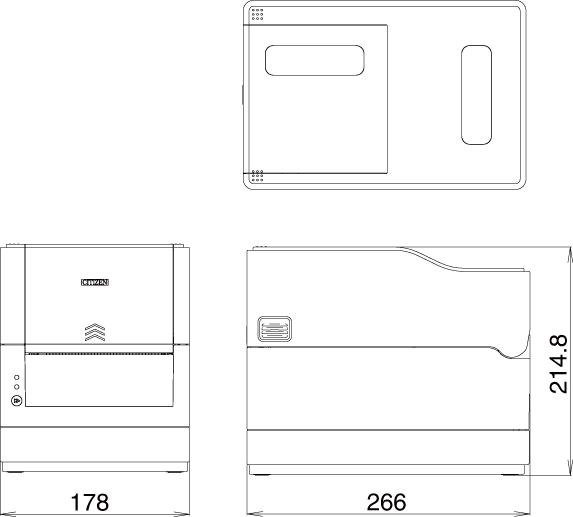

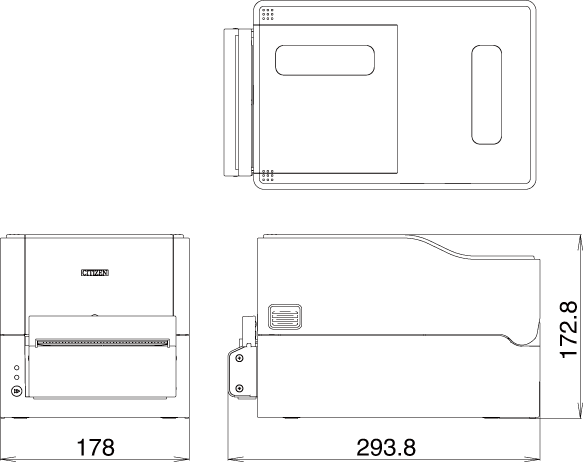

CL-E321X***NA (standard model)

CL-E321X***NS (model with AC adapter storage case)

* The figure illustrates the standard model with AC adapter case.

CL-E321X***BC (model with cutter)

- 1.Media window

- Enables users to check the media level.

- 2.Top cover

- Opens upward so users can replace or set media.

- 3.Operation panel

- Includes 2 LEDs and 1 key.

- Enables users to perform different printer operations and check printer status.

- 4.Cover release buttons

- The cover is opened by pressing the buttons on both the right and left sides.

- 5.Push marks

- 6.AC adapter case

- 7.Auto cutter

- 8.Ribbon window

- Allows you to check the amount of ribbon that is remaining.

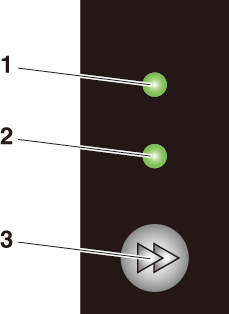

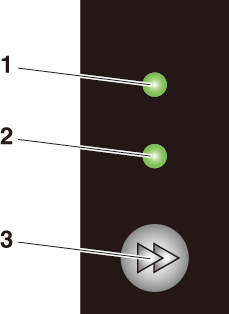

Operation panel

The operation panel includes 2 LEDs and 1 key.

- 1.Power LED

- Turns on when the power is turned on and turns off when the power is turned off.

- 2.Status LED

- Turns on or flashes in green, red, and amber depending on the printer status.

| Color |

Lights/flashes |

Status |

| Green |

On |

Printer is online |

| Flashes |

Receiving data |

| Amber |

On |

Startup |

| Red, green, amber |

Flashes |

Error or alarm |

| - |

Off |

Paused |

- 3.FEED key

- Feeds media when pressed while the printer is waiting to receive data.

- Pressing and holding this key for at least 3 seconds changes the operation mode to

the online configuration mode.

- Turning on the power to the printer while pressing and holding the FEED key with the cover closed changes starts the printer in the special function mode.

- Other key operation varies depending on the currently selected mode. Refer to “FEED Key Operation” for more information.

FEED Key Operation

Online state (status LED is solid green)

- (1)Press the FEED key while the printer is not receiving data to feed media.

- If label media is specified, the printer automatically stops after detecting the beginning

of media. If continuous media is specified, the printer stops after a certain amount

of feed operation.

- If Tear off mode is selected in the Function Select setting, the printer feeds media

to the tear-off position.

- For models with a cutter, the printer will feed media to the cut position and then

cut the media.

- (2)Press and hold the FEED key for at least 3 seconds while the printer is not receiving data to change the

operation mode to the online configuration mode.

Printing (status LED is solid or flashing in green)

Press the FEED key while the printer is printing or receiving data to pause the printer.

- The status LED turns off, and the printer pauses.

- If the FEED key is pressed while the printer is printing, the printer will finish printing the

current label and then stop.

Press the FEED key again to resume printing operation for the remaining labels in the print job.

Paused (status LED is off)

Press and hold the FEED key to change to the clear job mode.

Error/alarm has occurred (status LED flashes in red, green, or amber)

Press the FEED key to clear the error or alarm.

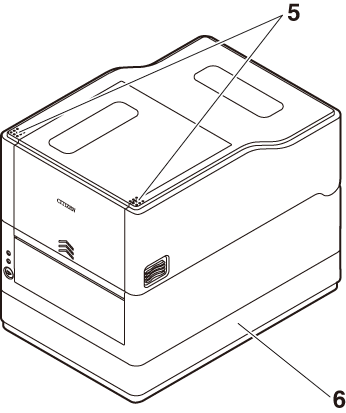

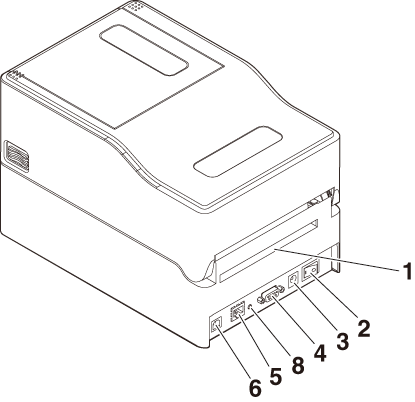

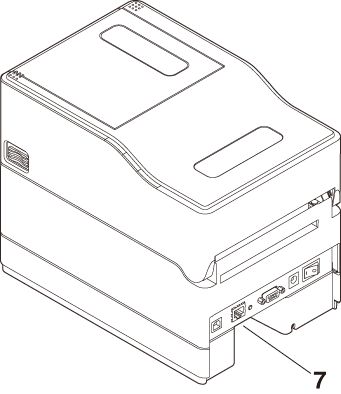

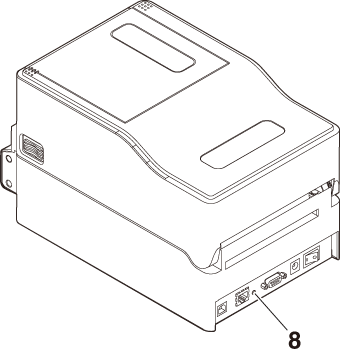

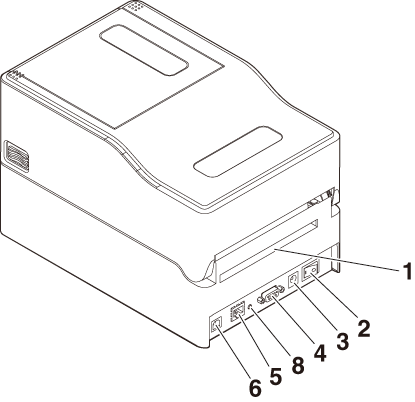

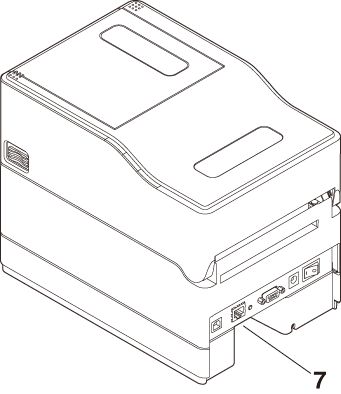

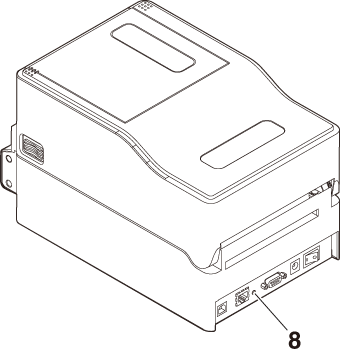

Rear of Printer

CL-E321X***NA (standard model)

CL-E321X***NS (model with AC adapter storage case)

CL-E321X***BC (model with cutter)

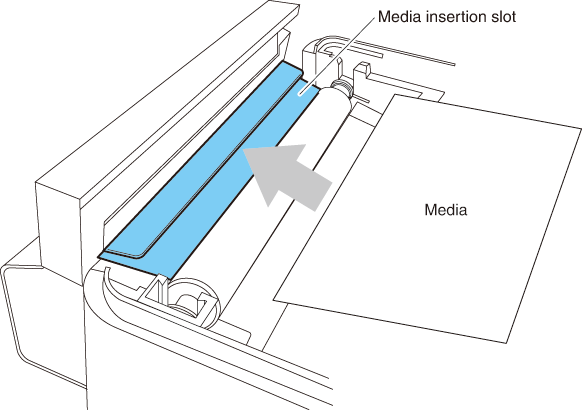

- 1.External media feed port

- This port is used to feed media into the printer.

- 2.Power switch

- Turns the printer power supply on and off.

- 3.DC jack

- Connects to the included AC adapter.

- 4.D-SUB 9pin serial interface

- 5.Ethernet Interface

- 6.USB interface

- 7.AC port

- 8.Ethernet panel button

- This button prints and initializes network settings.

CAUTION

- Do not connect a USB cable to the Ethernet interface. Doing so may damage connectors/interfaces.

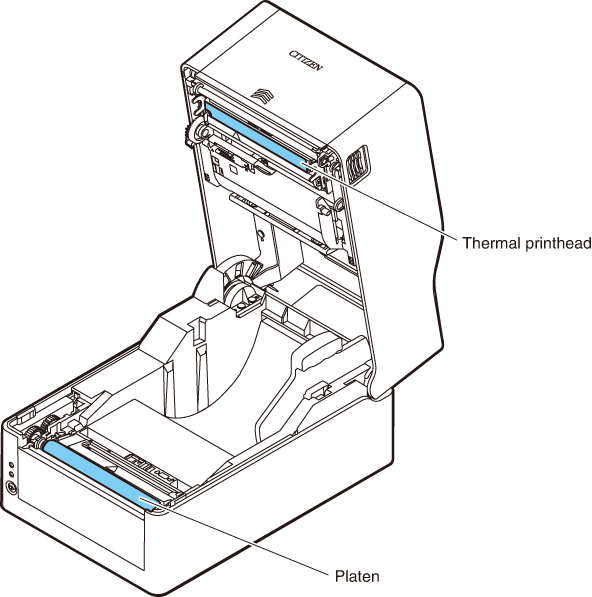

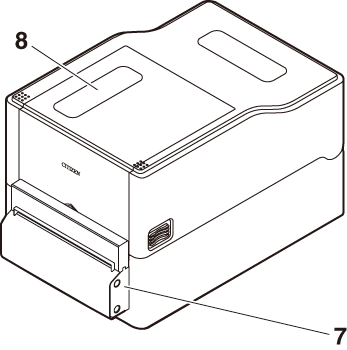

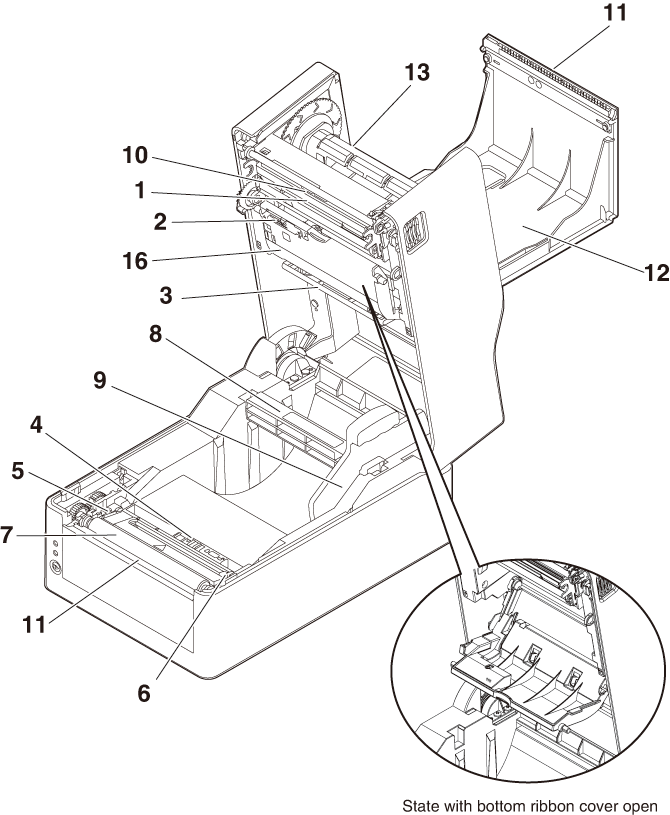

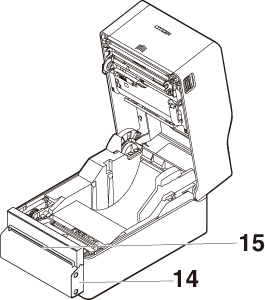

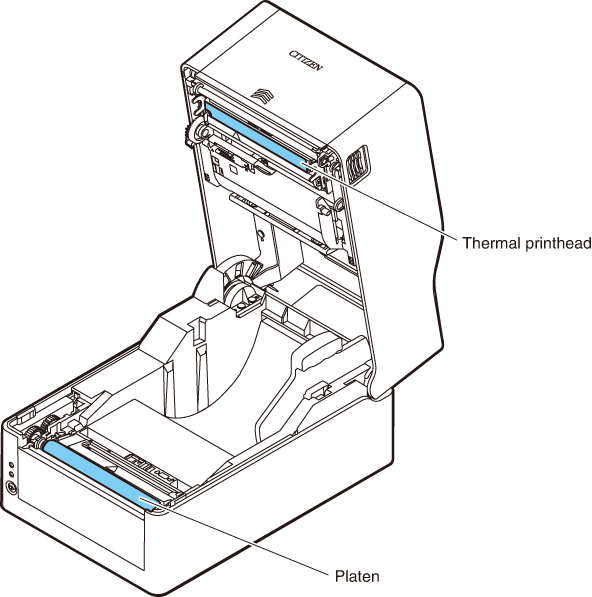

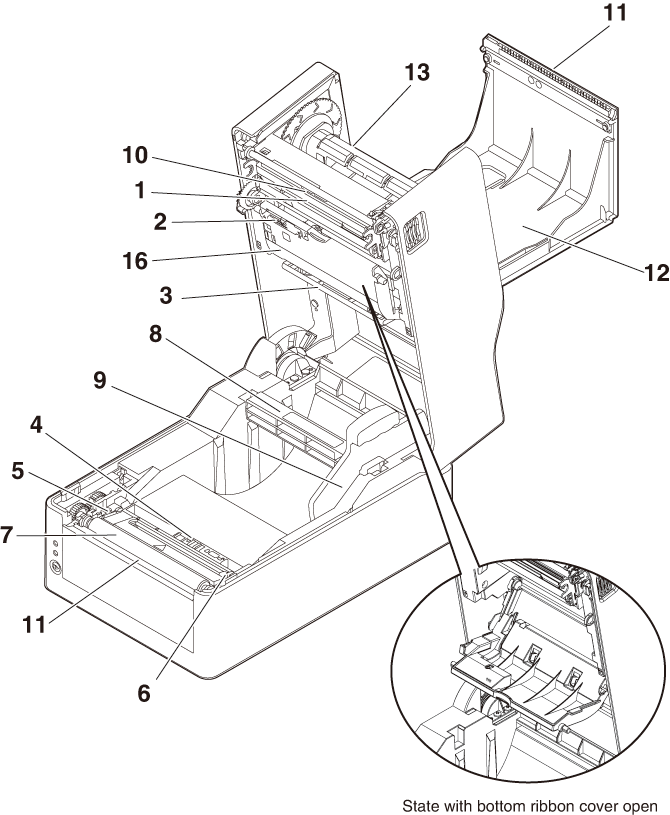

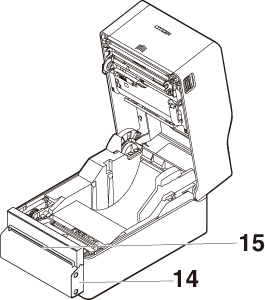

Inside of Printer

CL-E321X***NA (standard model)

CL-E321X***BC (model with cutter)

- 1.Thermal head

- Prints characters and graphic data on paper (paper rolls).

- 2.Upper sensor

- This sensor detects the media position.

- 3.Media damper

- When using roll media, absorbs tension generated by media feed operations to prevent

print errors.

- 4.Bottom sensor

- This sensor detects the media position.

- Devices are equipped with lock mechanisms.

- 5.Fixed left-side media guide

- 6.Adjustable right-side media guide

- 7.Platen roller

- This roller transports media.

- 8.Media shaft

- 9.Media shaft guide

- 10.Head balance adjustment slider

- 11.Manual cutter (Upper/Bottom)

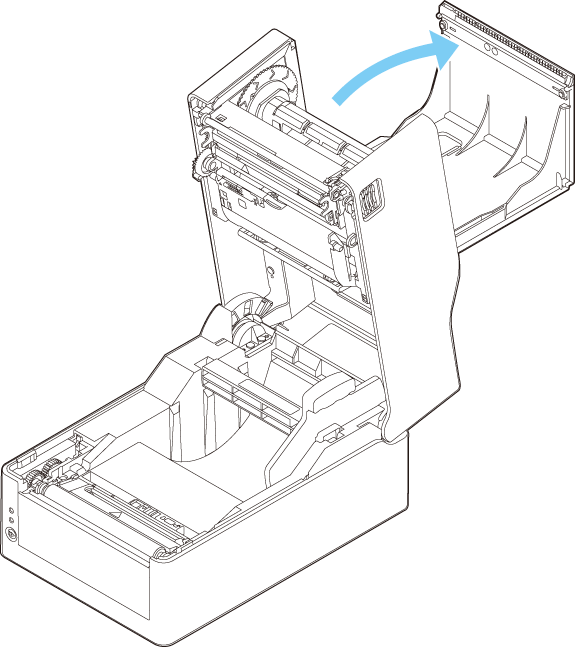

- 12.Top ribbon cover

- Open this to replace or install the ribbon.

- 13.Ribbon shaft

- Pass the shaft through the core of the ribbon to install the ribbon in the printer.

- 14.Auto cutter

- 15.Media discharge port

- 16.Bottom ribbon cover

- Open this to replace or install the ribbon.

Printing Preparation Process

The printer must be set up according to the following process before printing can

be performed.

Refer to the description of each section for detailed information on each step of

the process.

- 1.Unpack and check the package contents

- 2.Physical installation

- 3.Loading Media

- 4.Loading a Ribbon

- 5.Adjusting Media Sensor Positions

- 6.Connecting the AC Adapter

- 7.Connecting the Printer to a Host Computer

- 8.Operation Check

- 9.Installing the Printer Driver onto the Host Computer

- 10.Installing the Configuration Application onto the Host Computer

- 11.Printing

- Perform a test print from the printer driver installed on the host computer.

Loading Paper

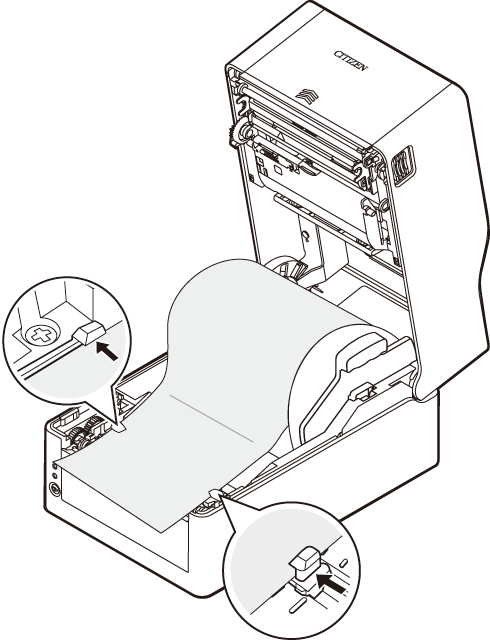

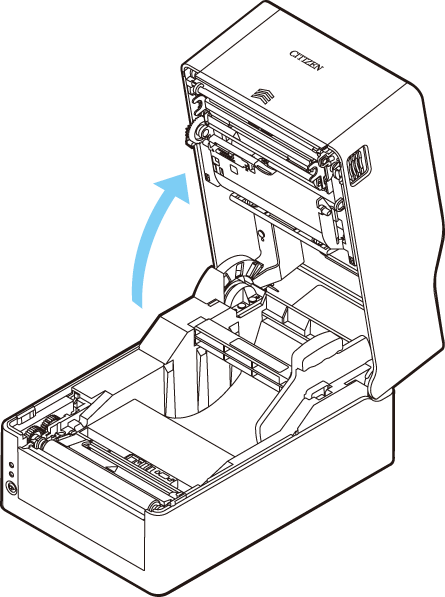

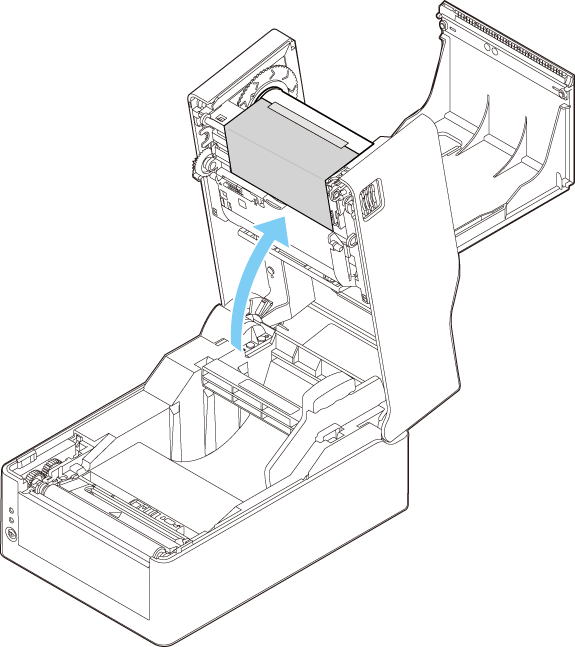

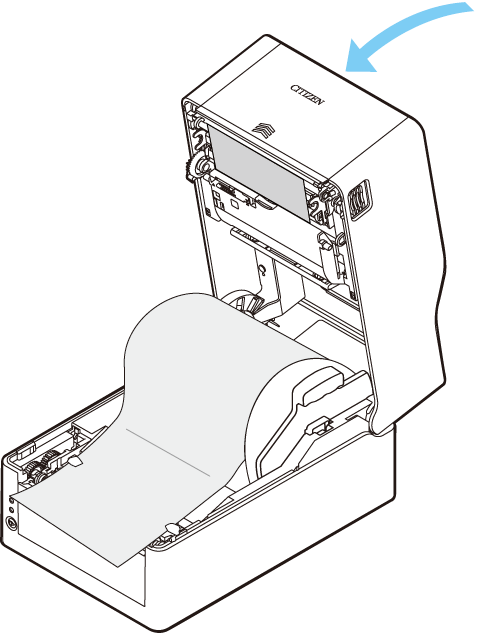

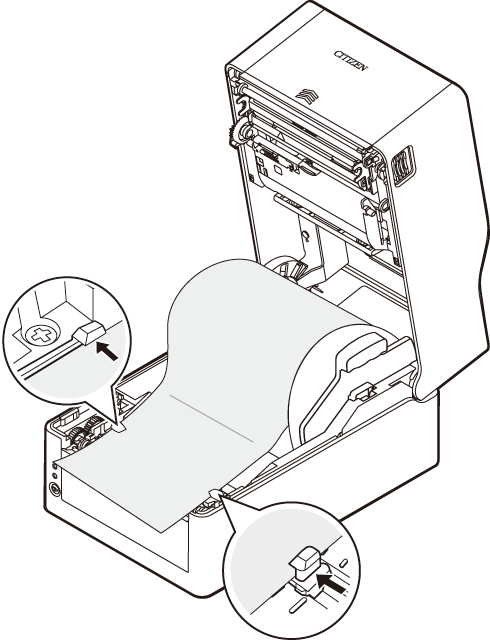

- 1.Press the cover release buttons on both the right and left sides to open the top cover.

CAUTION

- Note the following precautions when the top cover is open.

- Do not touch the thermal head.

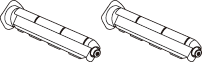

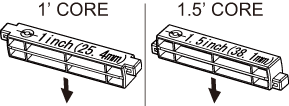

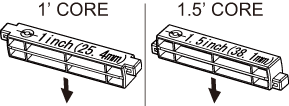

- 2.Insert the media shaft through the core of the media roll and then install the media

shaft guide.

- The media shaft is designed to accommodate both 1-inch and 1.5-inch media roll cores

by flipping it upside down. The media shaft has markings indicating which side supports

the different core sizes. Select the media shaft orientation in accordance with the

size of the media roll core.

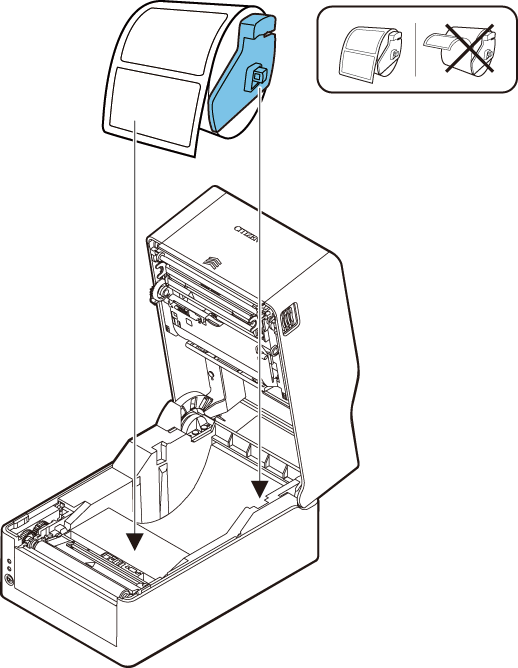

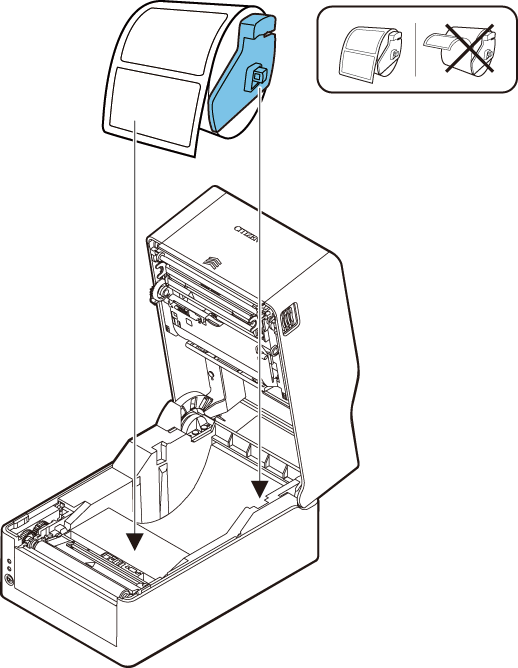

CAUTION

- Use media rolls that have the print surface on the outer side. Do not use media rolls

that have the print surface on the inner side. Labels may peel when such media roll

is back-fed.

- If the media shaft is not installed correctly, the top cover or bottom of the printer

will prevent media from feeding properly and cause paper jams.

- 3.Set the media so that the media shaft guide is on the right side of the media when

looking at the front of the printer.

- 4.Press the media shaft guide onto the media roll so that the center of the media aligns

with the center of the media shaft and then set the media into the printer.

- 1.Assemble the media shaft and media shaft guide.

- 2.Insert the media shaft through the core of the media roll and then set the assembly

into the printer.

- 3.Set the media in the printer and slide the media to the left from the perspective

of looking at the front of the printer. Insert the media shaft guide into the paper

at this position.

CAUTION

- Too much abutment force by media shaft guide may cause improper feeding of media,

which may negatively impact print quality.

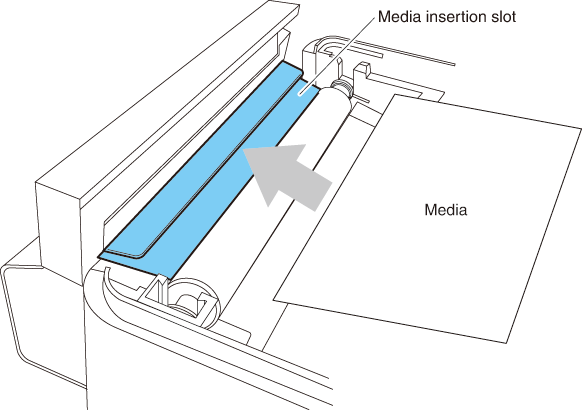

- 5.If using a model with a cutter (CL-E321X***BC), pass the media through the cutter slit.

CAUTION

- Insert media into the slit correctly. Failure to do so may result in improper feeding

of media, which may cause paper jams.

- 6.Make sure the media is in abutment with the left media guide and then adjust the position

of the right media guide in accordance with the media width.

- From the front of the printer, set in front of the edge of media by approximately

10 mm.

CAUTION

- Too much abutment force of the right movable paper guide may cause improper feeding

of media, which may negatively impact print quality.

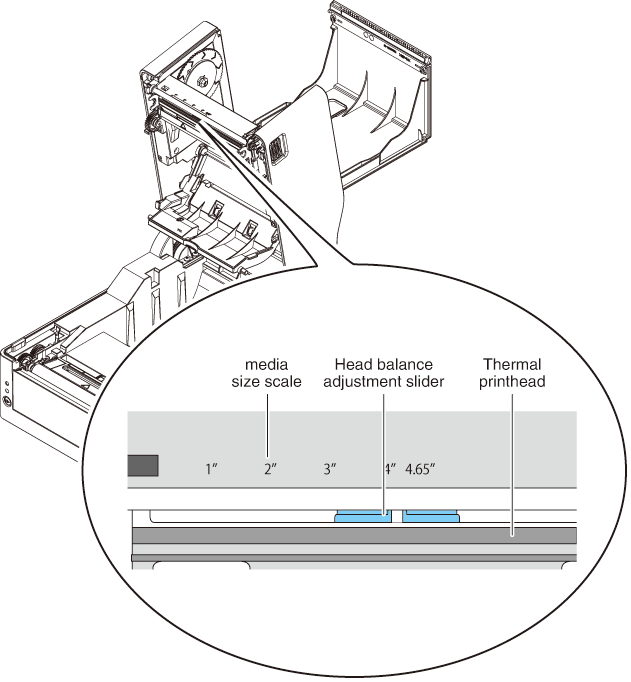

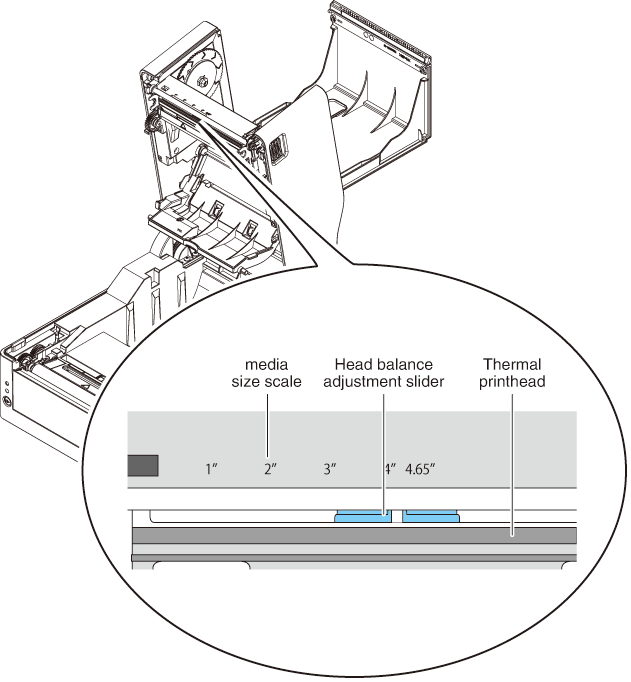

- 7.Slide the head balance adjustment slider located near the thermal head along the media

size scale (inch) so that the position of the notch in the slider matches the media

width.

CAUTION

- Adjust the head pressure horizontal balance carefully so as not to damage the thermal

head.

Damaged thermal heads will result in poor printing, paper jams, and malfunction.

- If using media in thermal-transfer printing with a width of 2 inches or less, we recommend

setting the head balance adjustment slider to 2.5" (between 2" and 3").

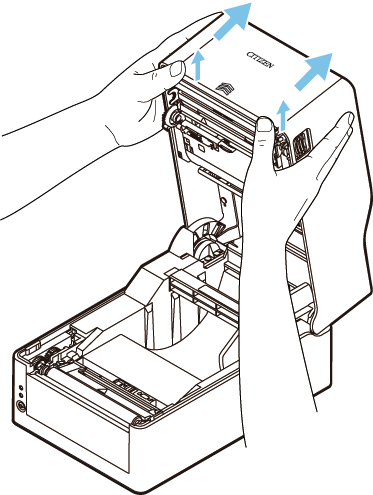

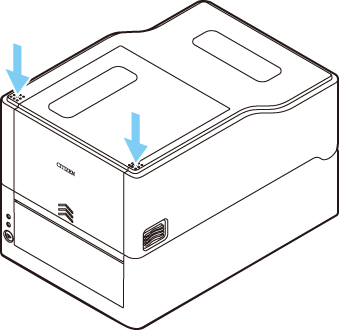

- 8.Close the top cover.

CAUTION

- Press the push marks on left and right sides at the top of the top cover and ensure

that the top cover hooks on each side lock securely.

If the top cover is not securely locked, this may cause print errors, paper jams,

and malfunction.

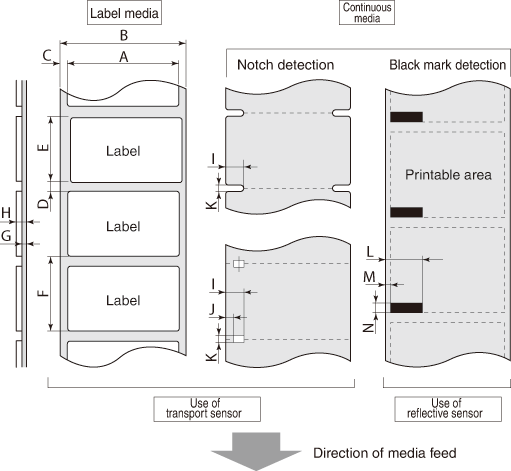

Compatible Paper Types

CAUTION

- Continuous label media cannot be used with the model that has a cutter. Using such

media may cause the label media adhesive to accumulate on the cutter blade, which

could result in a failure.

Refer to the following specification table for information on the types of media compatible

with this printer.

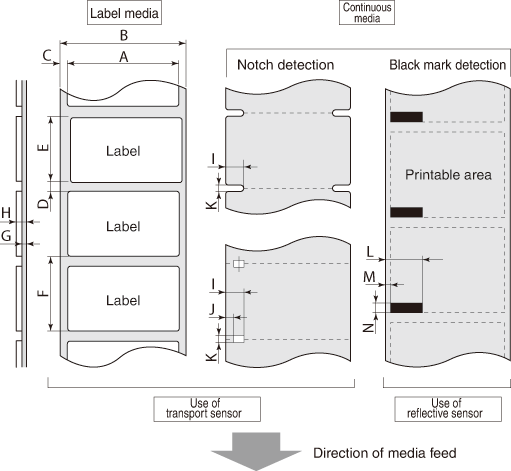

|

Minimum value |

Maximum value |

| mm |

inch |

mm |

inch |

| A |

Label width |

21.50 |

0.83 |

118.00 |

4.65 |

| B |

Backing paper width |

25.40 |

1.00 |

118.00 |

4.65 |

| C |

Left edge position of label |

0 |

0 |

2.54 |

0.10 |

| D |

Label gap length |

2.54 |

0.10 |

2,539.75 (CL-E321)1,270.00 (CL-E331) |

99.99 (CL-E321)

50.00 (CL-E331) |

| E |

Label length |

6.35 |

0.25 |

2,539.75 (CL-E321)1,270.00 (CL-E331) |

99.99 (CL-E321)

50.00 (CL-E331) |

| F |

Label pitch |

8.89 |

0.35 |

2,539.75 (CL-E321)1,270.00 (CL-E331) |

99.99 (CL-E321)

50.00 (CL-E331) |

|

|

| G |

Backing paper thickness |

0.06 |

0.0025 |

0.125 |

0.0049 |

| H |

Total media thickness |

0.06 |

0.0025 |

0.19 |

0.0075 |

|

| I |

Notch right edge position |

8.3 |

0.32 |

60.80 |

2.39 |

| J |

Notch left edge position |

0 |

0 |

57.20 |

2.25 |

| K |

Notch length |

2.54 |

0.10 |

17.80 |

0.70 |

| L |

Black line right edge position |

15.00 |

0.59 |

66.50 |

2.62 |

| M |

Black line left edge position |

0 |

0 |

51.50 |

2.02 |

| N |

Black line length |

3.18 |

0.125 |

17.80 |

0.70 |

- Use the transmissive sensor when using media that has both gaps between labels and

black lines.

- Use the transmissive sensor when using fanfold media.

- If the label pitch is 1 inch or less, configure an accurate label pitch with the [Small Media Adjustment] setting.

- Use carbon-based ink with an OD value of at least 1.5 to print black lines.

- The stop position and cut position may change depending on the width or type of media

that is used.

Adjust these positions using the Paper Position setting.

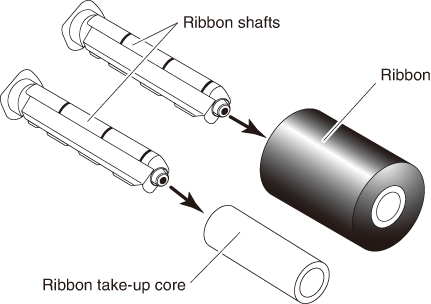

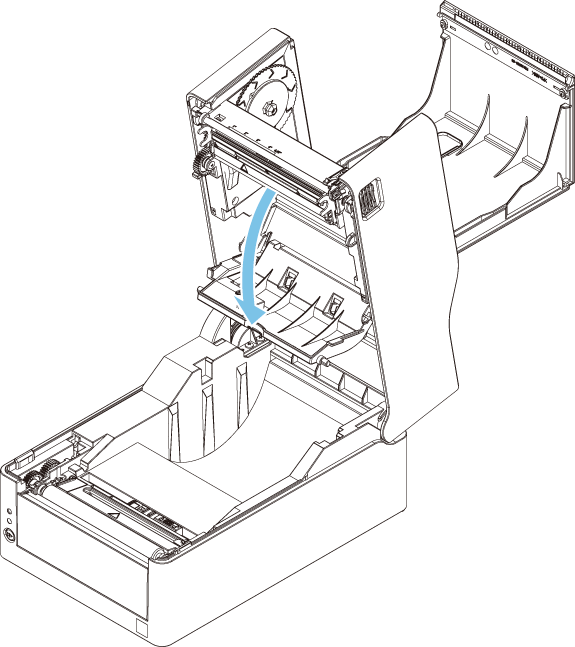

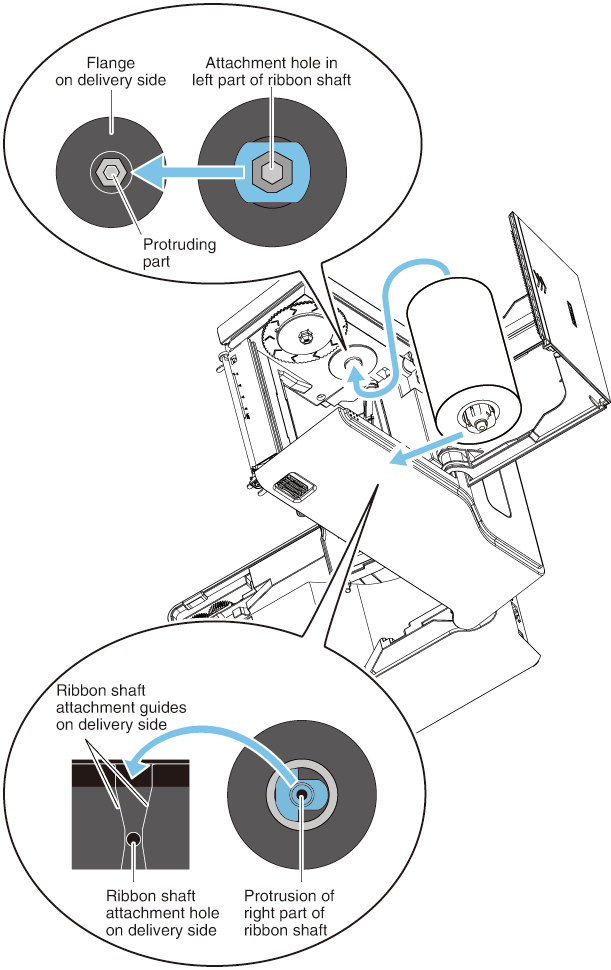

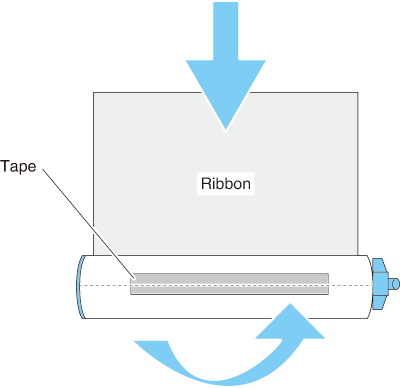

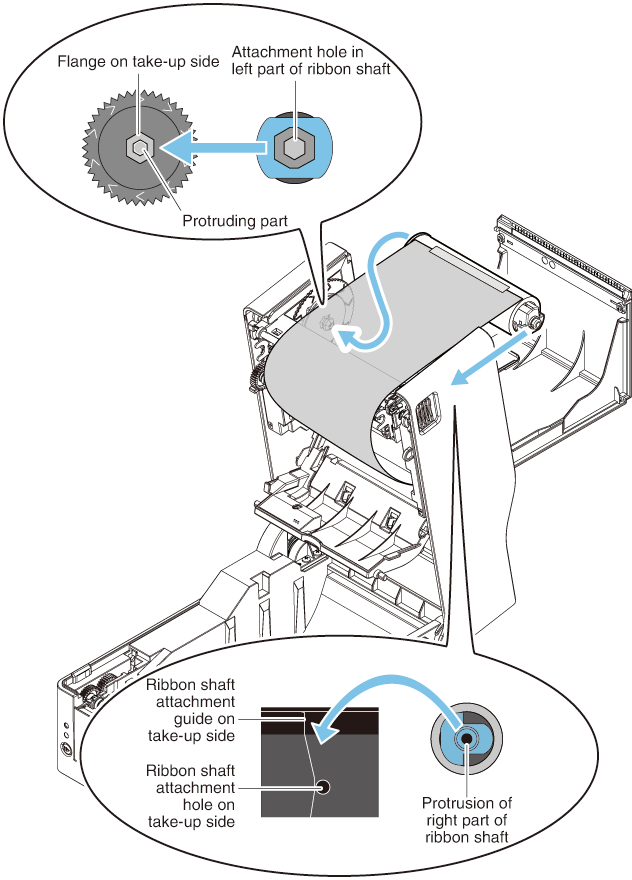

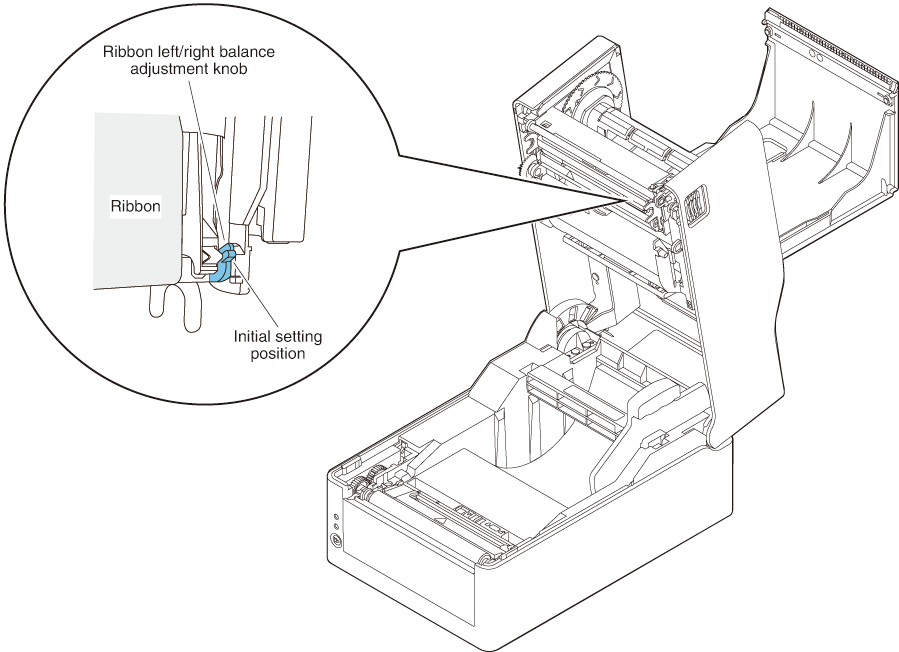

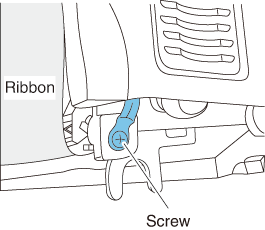

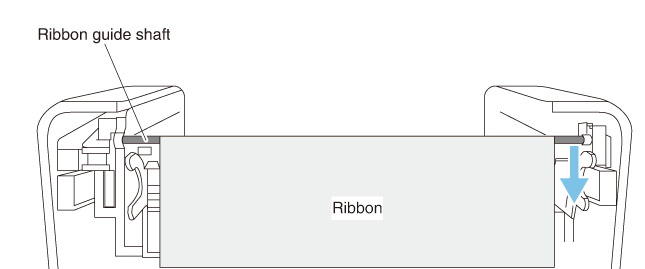

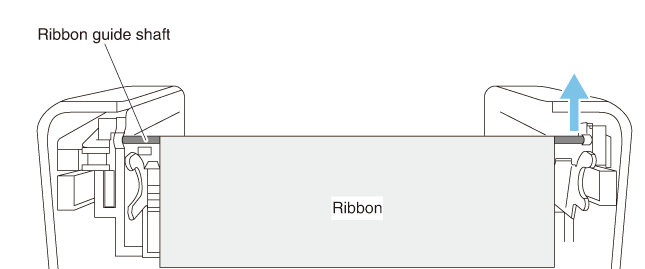

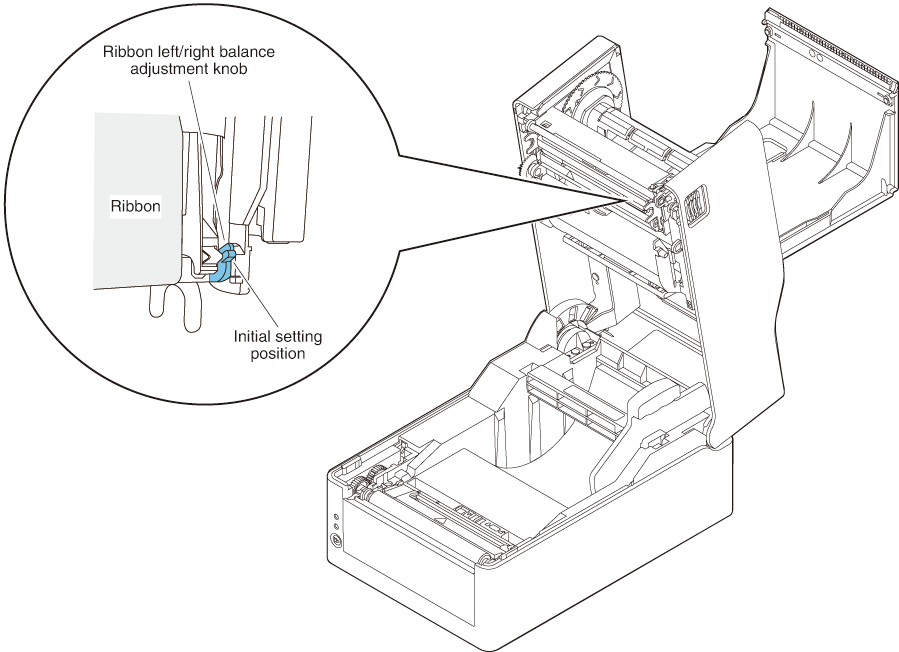

Loading a Ribbon

How to Load a Ribbon

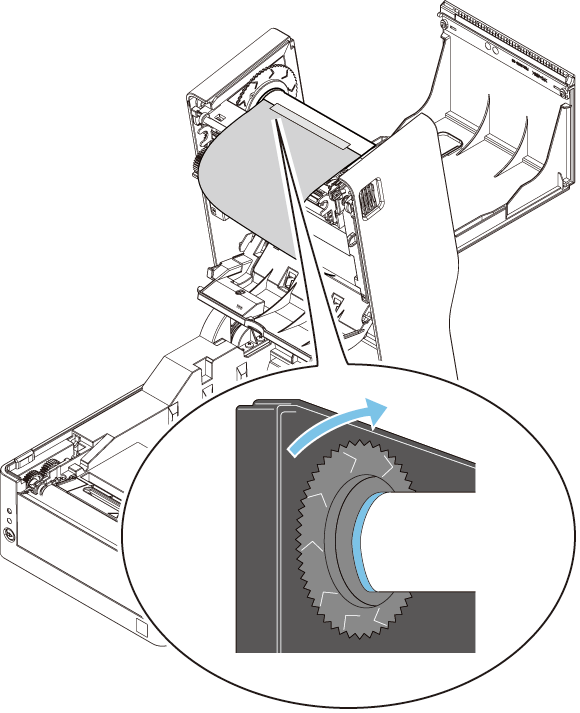

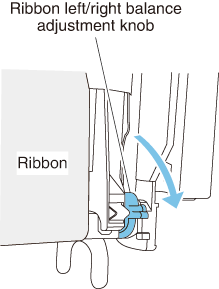

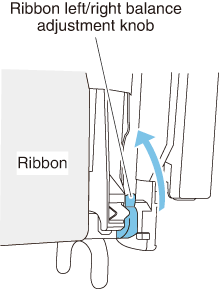

Adjusting the Left/Right Balance of the Ribbon

If the left/right balance of the ribbon needs to be adjusted, adjust it by moving

the ribbon left/right balance adjustment knob.

If wrinkles are occurring in the ribbon, make the adjustment described in the following

procedure.

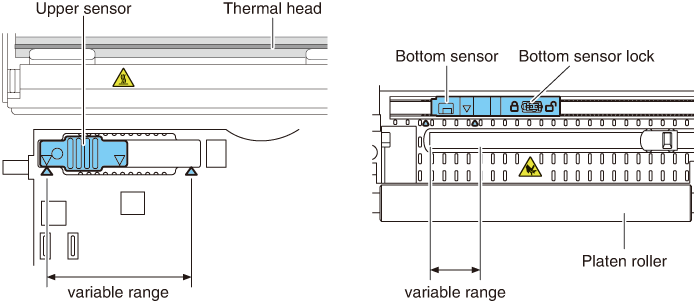

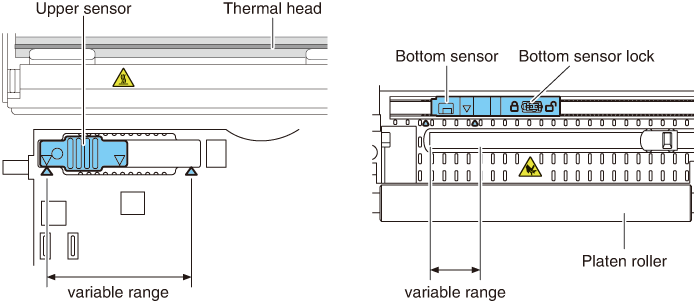

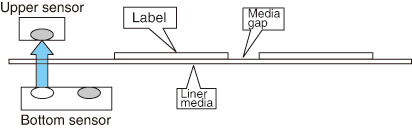

Adjusting Media Sensor Positions

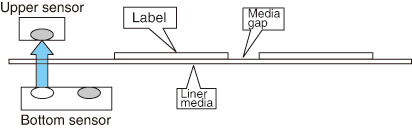

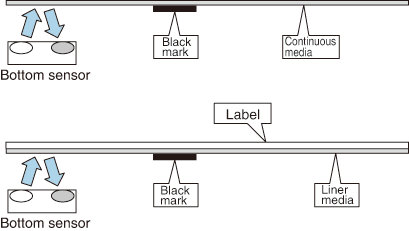

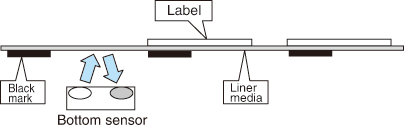

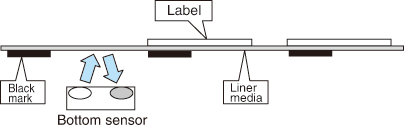

This section describes the procedure to adjust sensors when loading media. Transmissive

and reflective sensors can be used for the media sensors.

The printer comes from the factory equipped with a transmissive sensor. The media

sensor must be replaced with a reflective sensor for certain types of media.

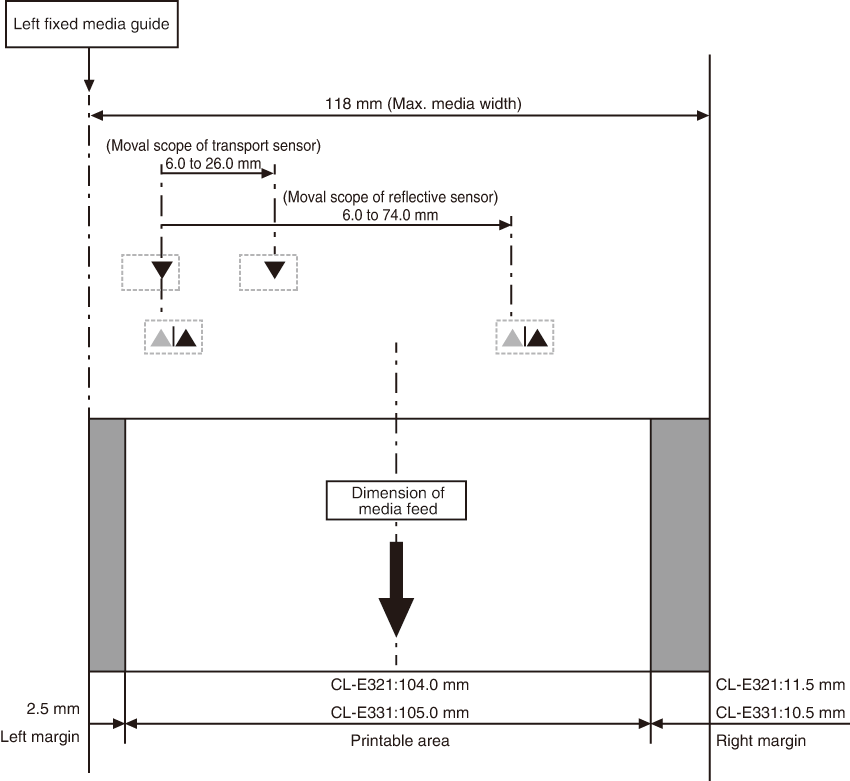

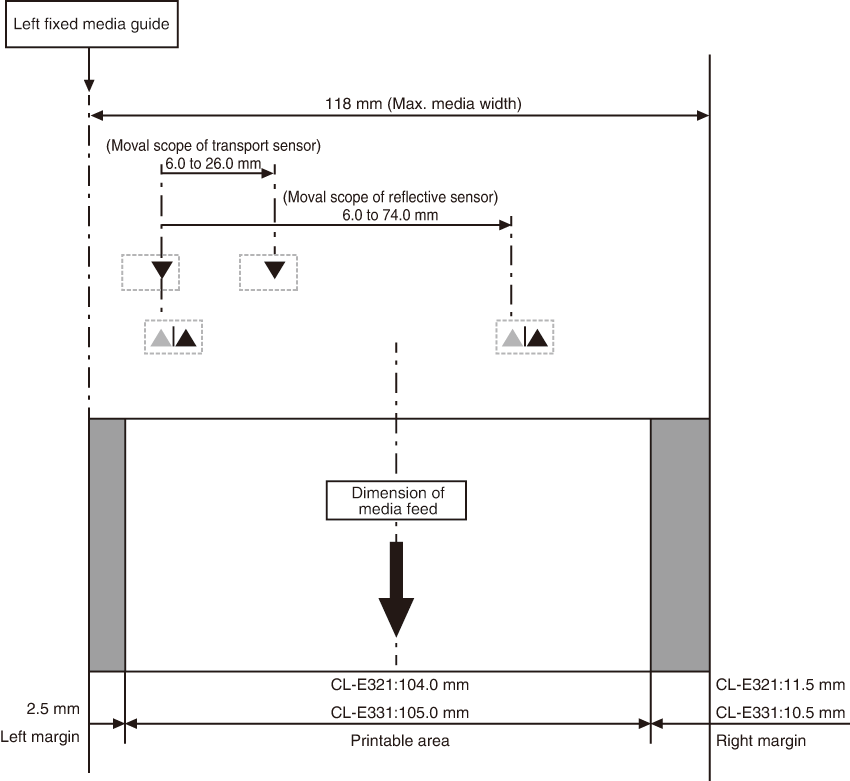

Range of Paper Sensor Adjustment

The following figure illustrates the range of media sensor adjustment.

Transmissive Sensor Adjustment

- ●Adjust the position of the bottom sensor and upper sensor in accordance with the media

width.

- Move the bottom sensor and upper sensor by the same number of steps from the position

of the triangle (▲).

- The range of bottom sensor and upper sensor horizontal adjustment is 10 steps between

the triangle marks (▲).

- Use a pen or other object with a narrow tip to unlock the bottom sensor and then reposition

it.

Lock the sensor in place once the new position has been determined.

CAUTION

- The bottom sensor and upper sensor must be in alignment with each other.

- Attempting to move the sensor while still locked may damage it.

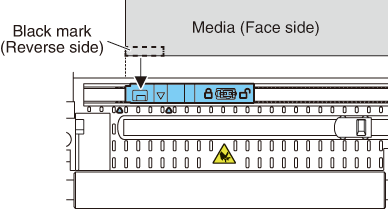

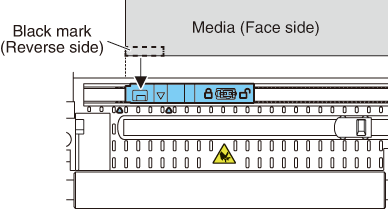

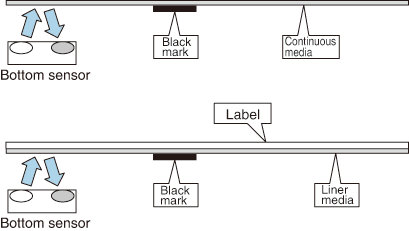

Reflective Sensor Adjustment

- ●Set the bottom sensor at a position so that the center of the sensor window is in

alignment with the center of the black line.

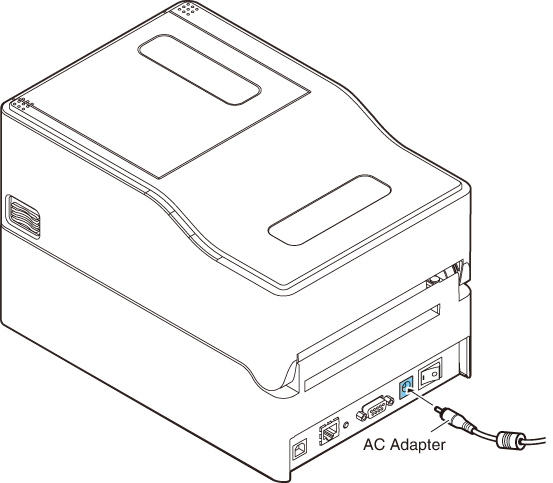

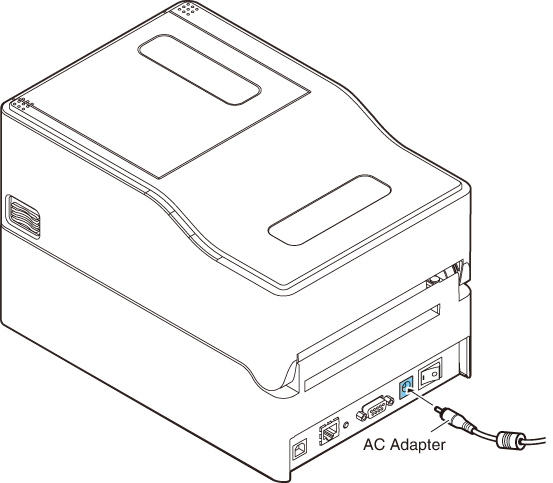

Connecting the AC Adapter

CAUTION

- Use the dedicated AC adapter designed for this device.

- Make sure the power switch on the printer is turned off before connecting the AC adapter.

- Insert the AC adapter connector completely into the DC jack.

- 1.Insert the DC plug on the output side of the AC adapter into the DC jack in the printer.

- 2.Insert the plug of the AC cord into an electrical outlet.

For a model with an AC adapter storage case

- ●Insert the plug of the AC cord into the AC port.

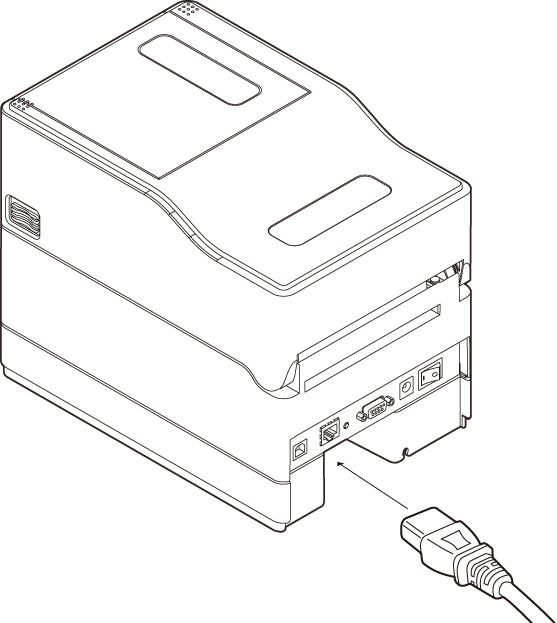

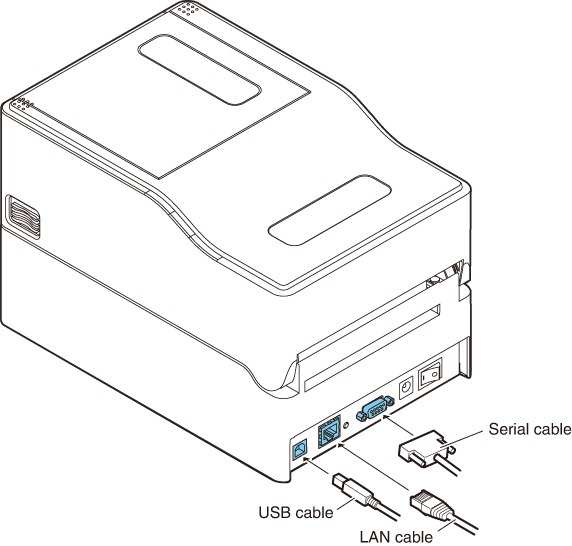

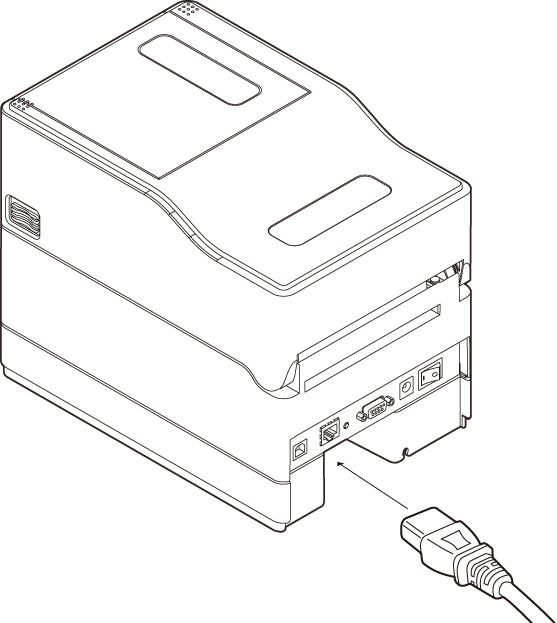

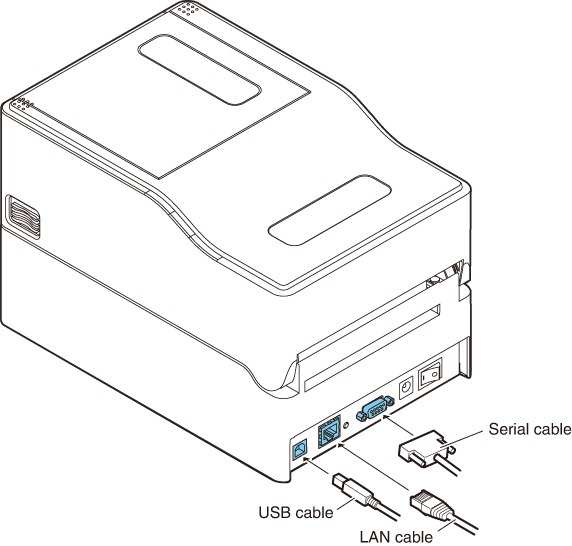

Connecting the Printer to a Host Computer

This printer is equipped with print data interfaces including a USB port, an Ethernet

port, and a serial port.

Use the following procedure to connect this printer to a host computer.

CAUTION

- Interface cables are required to connect the printer to a host computer.

- 1.Turn off the power to the printer and host computer.

- 2.Insert the cable into the appropriate interface port at the back of the printer.

- Tighten any locking screws to secure the cable.

- 3.Insert the other end of the cable into the appropriate interface port in the host

computer.

- Tighten any locking screws to secure the cable.

Using an Ethernet connection

Configure network settings as necessary.

CAUTION

- To check the current Ethernet settings, press the Ethernet panel button located next

to the Ethernet interface to printout the settings.

- To initialize Ethernet settings, press and hold the Ethernet panel button for at least

3 seconds. Once the buzzer emits a short tone, press and hold the Ethernet panel button

again within 3 seconds for at least 3 seconds.

Install the Printer Driver

Install the printer driver onto the host computer.

Printer drivers are available for download from the Citizen Systems support website.

The latest documentation, drivers, utilities, and other support information are also

available from this website.

http://www.citizen-systems.co.jp/support/download/printer/label/index_en.htmlOnce a printer driver has been downloaded, follow the on-screen instructions to install

the driver.

List of Settings

This section describes the procedures to configure printer settings using the LabelPrinterUtility.

The following table lists the settings configurable with LabelPrinterUtility.

| Home menu |

Sub menu |

Default |

Configurable range |

Notes |

| Page Setup |

Print Speed |

6 IPS |

CL-E321:

2 to 8 IPS

CL-E331:

2 to 6 IPS |

Sets the print speed |

| Print Darkness |

10 |

00 to 30 |

Adjusts the print density |

| Darkness Adjust |

00 |

-10 to 10 |

Fine adjustment of the density command |

| Print Method |

TT |

TT

DT

|

Selects thermal-transfer (ribbon) or direct-thermal media |

| Continuous Media Length |

4.00 inch

101.6 mm

|

CL-E321:

0.25 to 99.99 inch

6.4 to 2539.7 mm

CL-E331:

0.25 to 50.00 inch

6.4 to 1,270.0 mm

|

Sets the length of continuous mediaThe lower row shows millimeter values when using the printer in mm mode |

| Vertical Position |

0.00 inch

0.0 mm

|

-1.00 to 1.00 inch

-25.4 to 25.4 mm

|

Adjusts the printing start position |

| Horizontal Shift |

0.00 inch

0.0 mm

|

-1.00 to 1.00 inch

-25.4 to 25.4 mm

|

Adjusts the horizontal image position |

| Vertical Image |

(Datamax)

0.00 inch

0.0 mm

|

0.00 to 32.00 inch

0.0 to 812.8 mm

|

Adjusts the start position for creating images |

| (Zebra/Eltron)000 dots |

-120 to 120 dots |

| Auto Side Shift |

0 dots |

0 to 15 dots |

Shifts the horizontal print position by the specified number of dots for each sheet/label.

This is useful when significant load is placed on the portion of the thermal head,

such as when printing vertical borders.

|

| Media Sensor |

See Through |

See Through

Reflect

None |

Selects the type of label sensor type |

| Small Media Adjustment |

Off |

On

Off |

Setting for small label support |

| Small Media Length |

1.00 inch

25.4 mm

|

0.25 to 1.00 inch

6.4 to 25.4 mm

|

Sets the length for small label media |

| Symbol Set |

PM |

50 options |

Sets the character set |

| Home menu |

Sub menu |

Default |

Configurable range |

Notes |

| System Setup |

| Sensor Level |

1.5 V |

0.0 V to 3.3 V |

Sets the sensor threshold |

| Paper End Level |

3.00 V |

0.01 V to 3.30 V |

Sets the paper end level |

| Error Reporting |

On Printing |

On Printing

Immediate |

Error reporting setting |

| Buzzer Select |

Exec/Err |

Exec/Err

All

Error

Key

None |

Sets the conditions at which the buzzer is triggered |

| Metric/Inch |

Inch |

Inch

mm |

Sets the unit of measure |

| Max Media Length |

10.00 inch

254.0 mm

|

CL-E321:

1.00 to 99.99 inch

25.4 to 2539.7 mm

CL-E331:

1.00 to 50.00 inch

25.4 to 1,270.0 mm

|

Sets the maximum length of label media |

| Settings Lock |

Off |

On

Off |

Prevents changes via setting commands |

| Keyboard Lock |

Off |

On

Off |

Prevents changes via key operation |

| Control Code |

STD |

STD

ALT

ALT-2 |

Changes the command mode for DMX mode (only when Datamax® emulation is selected) |

| Media Power Up |

Off |

On

Off |

Sets the media length measuring function when the power is turned on (only when Zebra®

emulation mode is selected on international models)

|

| CI Lock |

Off |

On

Off |

Prevents changes via CI commands (only when Zebra® emulation mode is selected on international

models)

|

| Emulation Select |

DM4 (Datamax®)ZPI2 (Zebra®) |

DM4

DMI

DPP

ZPI2

EPI2 |

Datamax®/Zebra® compatibility selection

DM4 Datamax® 400

DMI Datamax® IClassTM

DPP Datamax® Prodigy Plus®

ZPI2 Zebra® ZPL2TM

EPI2 Zebra® EPL2TM |

| Emulation Auto Detect |

Full Auto |

On

Off

Full Auto |

Sets the emulation sensing function (international models only) |

| Home menu |

Sub menu |

Default |

Configurable range |

Notes |

| After Print - 1 |

AutoConfigure |

On |

On

Off |

Enables/disables the auto configuration of optional equipment.

On - Enables auto configuration (when a cutter is installed, mode is automatically configured

regardless of the Function Select setting)

Off - Disables auto configuration. Turn this setting Off and select operation with Function Select when you do not want to use the cutter if installed.

|

| Function Select |

Tear |

Off

Tear

Cut On(only valid for models with cutters) |

Selects the operation mode when AutoConfigure is Off. Each option has a specified media stop position. Enables operation of the applicable

device when selected.

|

Cutter Action

*Only valid for models with cutters |

Backfeed |

Backfeed

Through |

Cutter action setting

Prints only when AutoConfigure for a model with a cutter is On or when [Backfeed] is selected for the Function Select setting.

The [Backfeed] option performs a back-feed after each cut operation.The [Through] option continues the print operation at the trailing edge of each sheet/label from

the first sheet/label to the n-1 sheet/label when the number of copies is set to n.

A back-feed operation is then performed at the trailing edge of the last sheet/label

or when printing a single sheet/label.

|

| Home menu |

Sub menu |

Default |

Configurable range |

Notes |

| After Print - 2 |

Paper Position |

0.00 inch

0.00 mm

|

STD

0.00 to 2.00 inch

0.0 to 50.8 mm

Cut/Tear-

1.00 to 1.00 inch

-25.4 to 25.4 mm

|

Adjusts the stop position.

This setting is dependent on the Metric/Inch setting.

Each device has an initial stop position as configured with the settings previously

described. This setting sets a relative value from these other settings.

|

| Feed Key Action |

Feeds Media |

Repeat Last Set

Repeat Last One

Feeds Media |

Changes the operation of the FEED key

Repeat Last Set

Reprints a set of labels.

This setting is ignored when Zebra®* emulation mode is selected.

Repeat Last One

Reprints the last page only.

Prints only 1 sheet/label from the current number when using counts.

Feeds Media

Functions as the FEED key.

Disables reprinting.

|

| Home menu |

Sub menu |

Default |

Configurable range |

Notes |

| Interface*1 |

RS-232C Baud Rate |

9600 |

115200

57600

38400

19200

9600

4800

2400 |

Sets the baud rate of the serial interface |

| RS-232C Parity |

None |

None

Odd

Even |

Sets the communication parity of the serial interface |

| RS-232C Length |

8 bits |

8 bits

7 bits |

Sets the data length for the serial interface |

| RS-232C Stop bit |

1 bit |

1 bit

2 bits |

Sets the stop bits for the serial interface |

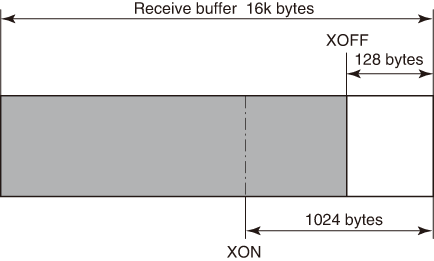

| RS-232C X-ON |

Yes |

Yes

No |

Enables/disables X-ON flow control for the serial interface |

| USB Device Class |

Printer |

Printer

VCOM |

Sets the USB device class |

| USB VCOM Protocol |

Auto |

Auto

DTR

X-ON |

Sets the USB VCOM protocol (flow control) |

| IPv4 Address |

169.254.001.010 |

000.000.000.000 to 255.255.255.255 |

Sets the IPv4 network address |

| IPv4 Subnet Mask |

255.255.000.000 |

000.000.000.000 to 255.255.255.255 |

Sets the IPv4 subnet mask |

| IPv4 Gateway |

000.000.000.000 |

000.000.000.000 to 255.255.255.255 |

Sets the IPv4 gateway |

| IPv4 DHCP |

On |

On

Off |

Enables/disables IPv4 DHCP |

| Host Name |

CL-E321:

CL-E321/300

Print Server

CL-E331:

CL-E331/303

Print Server

|

Any length from 0 to 31 characters long using single-byte letters (uppercase and lowercase),

numbers, and symbols

|

Name to assign to the device to identify the printer |

| Port Number |

9100 |

1024 - 65535 |

Print port number |

| Timeout |

60 |

0 - 300 |

Timeout time (in seconds) for connection with host machine

When the set number of seconds elapses without data being received from the host in

the state in which a session is established, a timeout occurs and the session is disconnected.

If this is set to 0, there will be no timeout.

|

| Action at timeout |

Close all |

Close all

Move next

|

Pending session processing when timeout

Sets whether to disconnect all other sessions or to enable sending and receiving when

there are two or more sessions established and a timeout occurs for the session that

was established first

|

| Transmits buffered data |

Disable |

Disable

Enable

|

Transmission data processing when host machine not connected |

| IPv6 |

On |

On

Off |

Enables/disables IPv6 |

| Fixed IPv6 Address |

On |

On

Off

|

Enables/disables IPv6 static network address |

| IPv6 Address |

0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0 |

0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0 -

255.255.255.255.255.255.255.255.255.255.255.255.255.255.255.255

|

Sets a IPv6 network address

Example: If the network address you wish to set is 2001:0db8:0000:0123:4567:89ab:cdef:feed,

specify the value for each network address field in decimal notation separated by

periods as shown below.

32.1.13.184.0.0.1.35.69.103.137.171.205.239.254.237

|

| IPv6 Prefix Length |

64 |

1 - 128 |

IPv6 prefix length setting (in bits) |

| IPv6 Gateway |

0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0 |

0.0.0.0.0.0.0.0.0.0.0.0.0.0.0.0 -

255.255.255.255.255.255.255.255.255.255.255.255.255.255.255.255

|

IPv6 gateway address setting

For how to specify an address, refer to the Notes column in “IPv6 Address”.

|

*1 Contains menus of option interface settings that can be configured for this printer.

| Home menu |

Sub menu |

Default |

Configurable range |

Notes |

| Global Configuration |

- |

Config Set 1 |

Config Set 1

Config Set 2

Config Set 3 |

Configuration number setting |

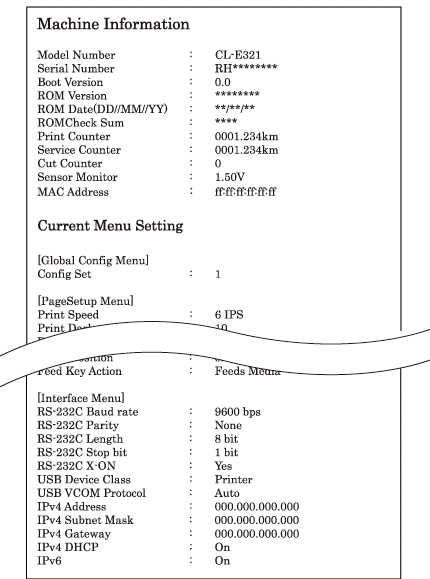

| Machine Information |

Model Number*2 |

- |

CL-E321 |

Displays the model number.

*Appears as “CL-E331” for the CL-E331 model. |

| Serial Number |

- |

RH******** |

Displays the serial number |

| Boot Version*2 |

- |

*.* |

Displays the boot version |

| ROM Version*2 |

- |

******** |

Displays the ROM version |

| ROM Date*2 |

- |

**/**/** |

Displays the ROM creation date |

| ROM CheckSum*2 |

- |

**** |

Displays the ROM checksum |

| Print Counter |

- |

****.*** km |

Displays the print counter |

| Service Counter |

- |

****.*** km |

Displays the service counter |

| Cut Counter |

- |

******* |

Displays the cut counter only for models with cutters |

| Sensor Monitor*2 |

- |

*.* V |

Displays the sensor level |

| MAC Address |

- |

**.**.**.**.**.** |

Displays the MAC address |

*2 This cannot be obtained with LabelPrinterUtility. To check the value, print the

list of settings.

Obtaining the LabelPrinterUtility

Using the LabelPrinterUtility

- ●Start LabelPrinterUtility.exe.

- Refer to the user manual for more information on using the application.

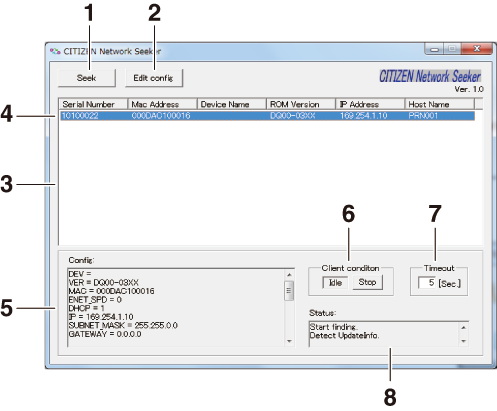

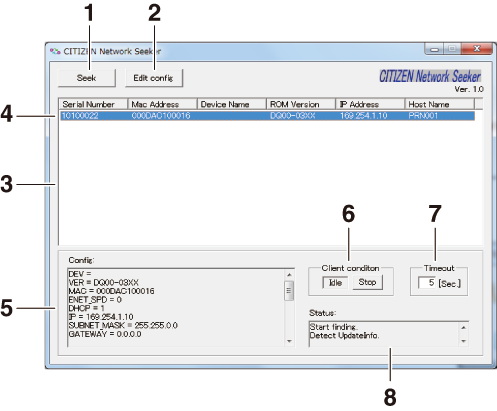

Starting Network Seeker

After obtaining the program “NetSeeker.exe” from the CD-ROM or our website, double click the program. A dialog box appears.

Start a search for printers by clicking the Seek button.

- 1.“Seek” button

- Start a search for Ethernet interface boards on the network.

- Waits for a response during the time configured with [Communication timeout].

- 2.“Edit config” button

- Change the settings of the selected board.

- 3.Board information list

- Single click to select a board and double click to change settings.

- 4.Board information

- Single click to select a board and double click to change settings.

- 5.Configuration display section

- View the settings of the selected board.

- 6.Client condition display

- When “Busy” is displayed, operations to search, change settings, and so on are prohibited.

- If you click “Stop”, the “Busy” status is cleared forcibly.

- 7.Communication timeout

- You can configure the time-out duration for searches and other operations.

- 8.Status log

- View the status of the utility.

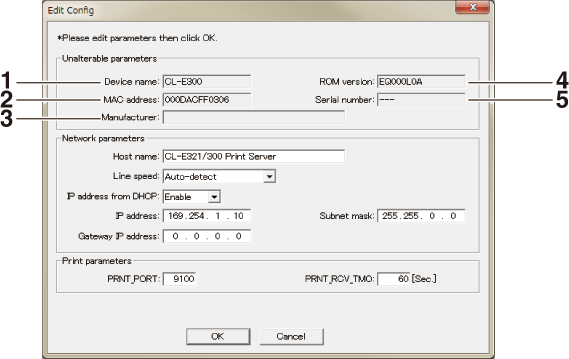

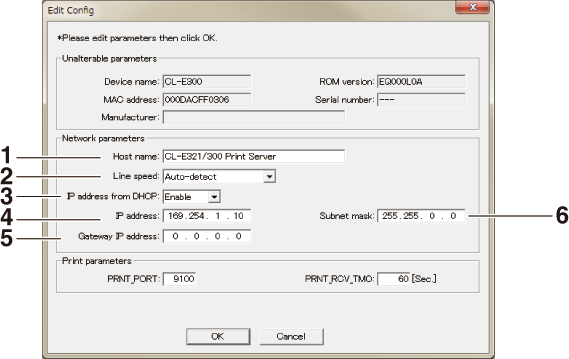

Changing Settings

You can configure an Ethernet interface board by selecting it at the main dialog box,

and then clicking “Edit config”.

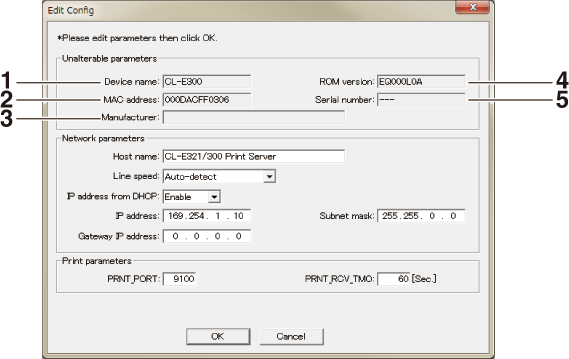

- These are unalterable parameters.

- These parameters are for display purposes only.

- 1.Device name

- 2.MAC address

- 3.Manufacturer

- 4.ROM version

- 5.Serial number

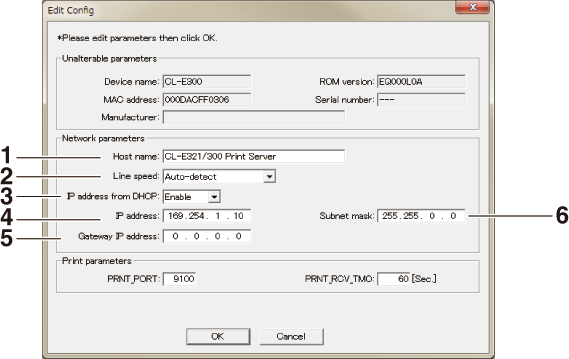

- These are changeable parameters.

- Users can change these parameters.

- 1.Host name

- 2.Line speed

- 3.IP address from DHCP

- 4.IP address

- 5.Gateway IP address

- 6.Subnet mask

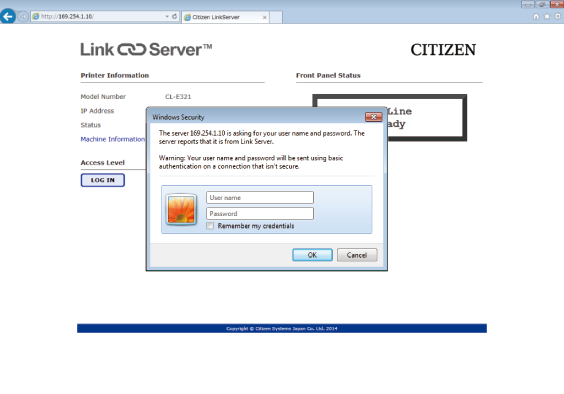

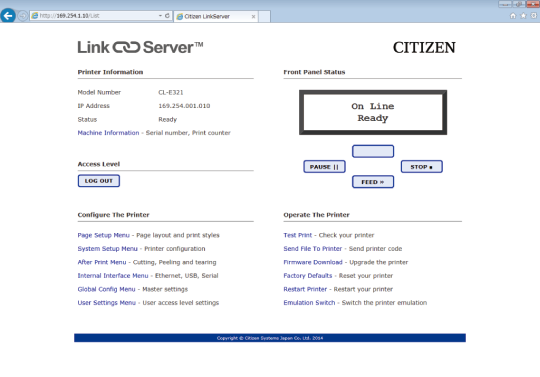

LinkServer user roles

LinkServer has the following three user roles available: User, Operator, and Administrator

The menus that appear for each user role can be changed to restrict operational access

to LinkServer.

The Home screen for the user role appears when first connecting.

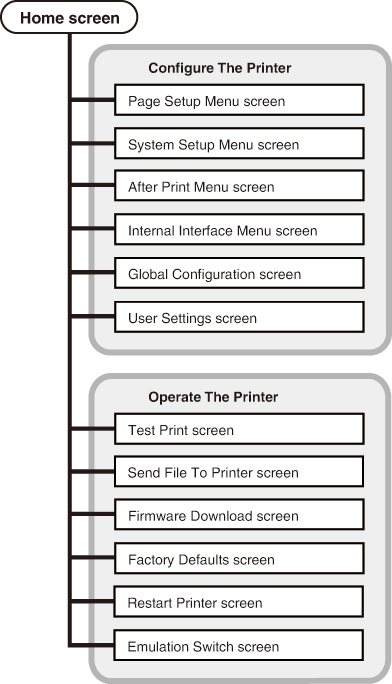

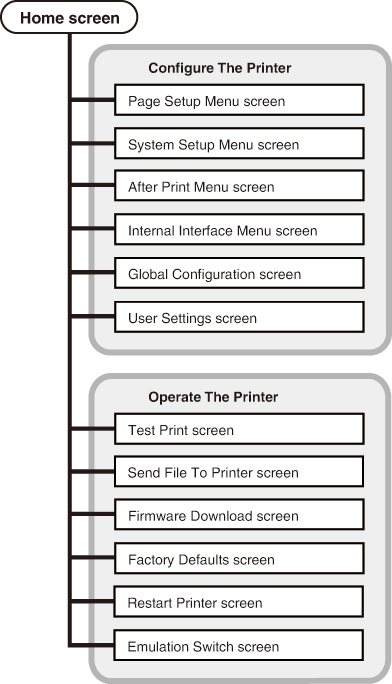

LinkServer menu configuration

The following figure illustrates the LinkServer menu configuration.

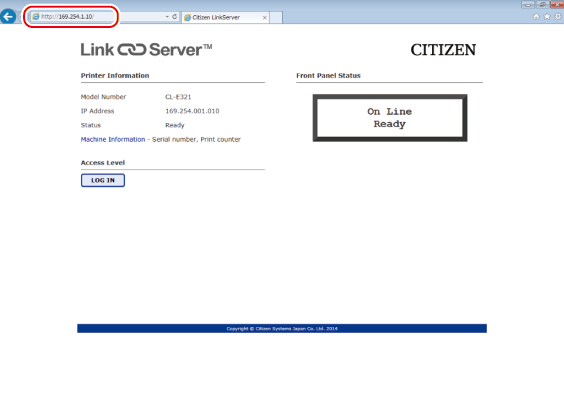

LinkServer connection procedure

Sensor Adjustment Mode

Use this mode to adjust media sensors (upper or lower) in accordance with the media

used.

Set the sensor position and media before starting this adjustment procedure.

Setting transmissive sensor positions and media

- 1.Align the bottom sensor and upper sensor with each other at the same position.

- 2.Peel a label and set the media so that only the backing paper (glassine paper) reaches

the platen roller and media sensor.

- If the media has black lines, do not set the media so that a black line is between

the sensors.

- 3.Adjust the sensors.

Setting reflective sensor positions and media

- 1.Adjust the reflective sensor so that it is underneath the media.

- 2.Set the media so that the media covers the platen roller and media sensor.

- Set that media so that black lines or gaps between labels do not cover the sensor.

- Using continuous media and label media without gaps between labels

- Set the media so that a section without a black line (or label face stock for label

media) does cover the platen roller and media sensor.

- Using label media with gaps

- Peel a label and set the media so that only the backing paper (glassine paper) reaches

the platen roller and media sensor.

- 3.Adjust the sensors.

Sensor adjustment

- 1.Turn on the power to the printer while pressing and holding the FEED key to start the printer in special function mode.

- 2.Press the FEED key once to select sensor adjustment mode.

- The buzzer emits 1 short tone.

The status LED also flashes in green.

- 3.Press and hold the FEED key for at least 3 seconds.

- 4.Release the FEED key once the buzzer emits a long tone and then press the FEED key again.

- The printer is now in sensor adjustment mode.

- 5.Press the FEED key to select either transmissive sensor or reflective sensor.

- Each press of the FEED key toggles between transmissive sensor and reflective sensor options.

| Sensor |

Buzzer |

Status LED |

| Color |

Interval |

| Transmissive sensor |

1 short tones |

Green |

Flashes |

|

| Press the FEED key ↕ |

| Reflective sensor |

2 short tones |

Green |

Flashes quickly |

|

- 6.Press and hold the FEED key for at least 3 seconds.

- 7.Release the FEED key once the buzzer emits a long tone.

- The sensor adjustment process starts.

- Once sensors have been adjusted, the buzzer emits 1 short tone.

- The buzzer emits 1 long tone if sensor adjustment fails. If this happens, check the

sensor and media positions.

- 8.To save and complete the sensor adjustments, press and hold the FEED key for at least 3 seconds.

- The buzzer emits 4 short tones, and the printer restarts.

Test print mode

This mode prints the test sample.

This printer can print test samples to label media and continuous media.

Printing test samples is a quick way to check print quality.

Load media and then perform the following procedure.

- 1.Turn on the power to the printer while pressing and holding the FEED key to start the printer in special function mode.

- 2.Press the FEED key twice to select test print mode.

- The buzzer emits 2 short tone.

The status LED also flashes quickly in green.

- 3.Press and hold the FEED key for at least 3 seconds.

- 4.Release the FEED key once the buzzer emits a long tone.

- The printer is now in test print mode.

- 5.Press the FEED key to select the media.

- Each press of the FEED key toggles between label media and continuous media.

| Media |

Buzzer |

Status LED |

| Color |

Interval |

| Label media |

1 short tones |

Green |

Flashes |

|

| Press the FEED key ↕ |

| Continuous |

2 short tones |

Green |

Flashes quickly |

|

- 6.Press and hold the FEED key for at least 3 seconds.

- 7.Release the FEED key once the buzzer emits a long tone.

- The test print process starts.

- Once the test sample has been printed, press the FEED key to print another test sample without a feed operation.

- 8.Once the test sample has been printed, turn the power to the printer off and on again

to reset the printer in the normal startup mode.

CAUTION

- Normal mode printing can also be performed when the printer is in test print mode.

Note that pressing the FEED key while the printer is in test print mode will not feed media. Instead, it will

print a test sample.

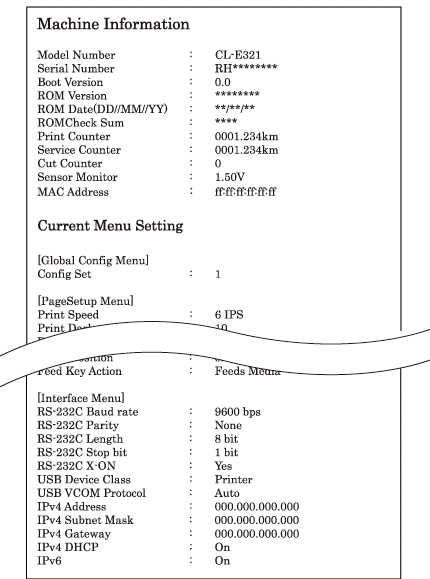

Configuration Print Mode

This mode is used to print the printer settings configuration when using continuous

media mode.

Printing the current settings configuration is a quick way to check the current configuration.

Example of printed settings configuration

Load media and then perform the following procedure.

- 1.Turn on the power to the printer while pressing and holding the FEED key to start the printer in special function mode.

- 2.Press the FEED key 3 times to select configuration print mode.

- The buzzer emits 3 short tone.

The status LED also flashes in amber.

- 3.Press and hold the FEED key for at least 3 seconds.

- 4.Release the FEED key once the buzzer emits a long tone.

- The configuration print process starts.

- Once the configuration has been printed, the printer will be in the online state.

- 5.To print configurations that include default settings, continue pressing and holding

the FEED for at least 3 seconds without releasing your finger at step 4.

- 6.Release the FEED key once the buzzer emits a long tone and then press the FEED key again.

- The process to print a configuration that includes default settings starts.

- Once the configuration has been printed, the printer will be in the online state.

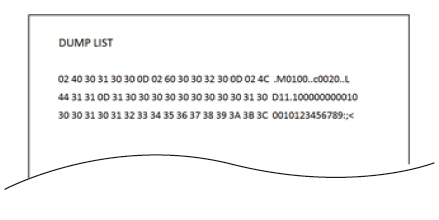

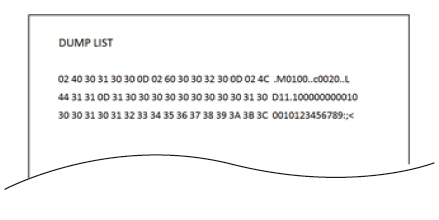

HEX Dump Mode

This mode is used to print a hex dump list (data received by the printer represented

in hex values) for confirmation of the data content.

Example of dump list printing

Load media and then perform the following procedure.

- 1.Turn on the power to the printer while pressing and holding the FEED key to start the printer in special function mode.

- 2.Press the FEED key 5 times to select HEX dump mode.

- The buzzer emits 5 short tone.

The status LED also flashes in red.

- 3.Press and hold the FEED key for at least 3 seconds.

- 4.Release the FEED key once the buzzer emits a long tone.

- The printer is now in HEX dump mode.

- 5.Press the FEED key to select the media.

- Each press of the FEED key toggles between label media and continuous media.

| Media |

Buzzer |

Status LED |

| Color |

Interval |

| Label media |

1 short tones |

Green |

Flashes |

|

| Press the FEED key ↕ |

| Continuous |

2 short tones |

Green |

Flashes quickly |

|

- 6.Press and hold the FEED key for at least 3 seconds.

- 7.Release the FEED key once the buzzer emits a long tone and then press the FEED key again.

- The hex dump list print process starts.

- 8.Once the HEX dump list has been printed, turn the power to the printer off and on

again to reset the printer in the normal startup mode.

Initialization Mode

This mode is used to initialize printer settings and the user memory area.

- 1.Turn on the power to the printer while pressing and holding the FEED key to start the printer in special function mode.

- 2.Press the FEED key 6 times to select initialization mode.

- The buzzer emits 6 short tone.

The status LED also flashes quickly in red.

- 3.Press and hold the FEED key for at least 3 seconds.

- 4.Release the FEED key once the buzzer emits a long tone.

- The printer is now in initialization mode.

- 5.Press the FEED key to select initialization of settings or initialization of the user memory area.

- Each press of the FEED key toggles between settings initialization and user memory area initialization.

| Initialization option |

Buzzer |

Status LED |

| Color |

Interval |

| Settings initialization |

1 short tones |

Green |

Flashes |

|

| Press the FEED key ↕ |

| User memory area initialization |

2 short tones |

Green |

Flashes quickly |

|

- 6.Press and hold the FEED key for at least 3 seconds.

- 7.Release the FEED key once the buzzer emits a long tone and then press the FEED key again.

- Once the selected initialization process completes, the printer restarts.

Plastic Surface of Printer and Platen

- ●Use a soft cloth or cotton swab dipped with a small amount of ethyl alcohol to wipe

off dust and dirt.

CAUTION

- Using an excessive amount of ethyl alcohol to clean the platen may cause surface deformation,

which would result in unstable feed operation.

Thermal head

- ●Use a cotton swab dipped with a small amount of ethyl alcohol.

CAUTION

- The thermal head is hot immediately after printing. Do not touch the thermal head

at this time.

- Do not touch the thermal head with bare hands or do not allow metals to come into

contact with the thermal head.

Troubleshooting

The status LED and buzzer are used to confirm error status when errors occur in the

printer.

| Status LED |

Buzzer |

Error |

Error description (in bold) and resolution |

| Flashes in red |

2 short tones |

Head Up Error |

Top cover is not closed correctly.

- Close the top cover correctly.

|

| Flashes in red |

3 short tones |

End of Media Error |

Printer has run out of media.Media is not set correctly.

- Open the top cover and load media or set the media correctly.

|

| Flashes in red |

4 short tones |

Media Load Error

Media Jam Error

|

Label gaps or black lines cannot be detected.

- Check the media sensor positions.

- Readjust the media sensors.

- Make sure the selection of transmissive sensor, reflective sensor, or continuous media

matches the type of media used.

Media cannot be transported.

- Open the top cover, remove any media blocking transport, and set the media again.

|

| Flashes in red |

5 short tones |

End of Ribbon Error |

Printer has run out of ribbon.

- Open the cover and replace the ribbon.

Ribbon is not loaded correctly.

- Open the cover and load the ribbon again.

|

| Flashes in red |

6 short tones |

Cutter Error

(models with cutters)

|

Cutter is not operating.

- Open the top cover and remove any media or other object blocking cutter operation.

- If the cutter does not operate after removing foreign objects, the cutter may not

be connected or installed correctly or may have failed. Contact your retailer.

Home position cannot be detected.

- The auto cutter may have failed. Contact your retailer.

|

| Flashes in amber |

Repetitions of long tones |

Head Low Temperature Error |

The thermal head is at a low temperature (approximately -10°C).

- Use the printer in proper environments of at least 0°C.

The thermal head is not connected.

- Check the cable connection with the thermal head.

|

| Flashes in amber |

None |

Head High Temperature Alarm

Motor High Temperature Alarm

|

The thermal head or feed motor is at a high temperature.

- Printing stops if the thermal head reaches approximately 70°C or more while printing.

Printing resumes automatically once the temperature falls to approximately 60°C or

lower.

- Printing stops if the feed motor reaches approximately 95°C or more while operating.

Printing resumes automatically once the temperature falls to approximately 85 ℃ or

lower.

|

| Flashes alternately in red and green |

Repetitions of long tones |

RS-232C Communication Error |

Parity error

Framing error

Receive buffer is full

Transmission buffer is full

- Check the communication settings.

|

| Flashes alternately in red and amber |

Repetitions of long tones |

Hardware Error |

A hardware error has been detected.

- Immediately turn off the power to the printer and contact your retailer.

|

This product does not have a broken head element check function so if there are vertical

white lines that you suspect are caused by a broken head element, clean the thermal

head and then perform a print check in the sample print mode.

If the white line problem is not resolved, the head element may be broken.

Basic Specifications

Printing

| Item |

Description |

| Print method |

Direct-thermal / thermal-transfer printing |

| Resolution |

CL-E321 |

Main scanning line density: 203 dots/inch (8 dots/mm) |

| Sub-scanning line density: 203 dots/inch (8 dots/mm) |

| Head dots: 864 dots (effective dots: 832) |

| CL-E331 |

Main scanning line density: 300 dots/inch (11.8 dots/mm) |

| Sub-scanning line density: 300 dots/inch (11.8 dots/mm) |

| Head dots: 1248 dots (effective dots: 1240) |

| Max. print width |

CL-E321 |

104 mm / 4.1 inch |

| CL-E331 |

105 mm / 4.1 inch |

| Max. print length |

CL-E321 |

(Datamax) 2539.7 mm/99.99 inch

(Zebra) 2540.0 mm/100.00 inch

|

| CL-E331 |

1,270.0 mm / 50.00 inch |

| Print density |

Print density is adjustable with software |

Print speed

| Item |

Description |

| Print speed setting |

CL-E321 |

2 to 8 inches per second in 1-inch increments (7 to 8 inches per second possible at

normal temperature using a print density of 10 and the recommended media and ribbon)

|

| CL-E331 |

2 to 6 inch per second in 1-inch increments |

Print mode

| Item |

Description |

| Batch mode |

Normal printing (single or multiple sheets) |

| Tear off mode |

Back-feeds to the tear-off position after printing is complete. (Labels may peel when

roll media is back-fed.)

|

| Cut mode |

Prints while cutting after every specified number of sheets/labels. Two types of cut

mode operations are available.

- Back-feed

- Cut-through

- (Cut-through pauses printing to cut the previous label when it reaches the cut position.

Printing resumes after the cut operation, but a gap may be formed at the location

where printing was paused.)

|

Media

| Item |

Description |

| Media types |

Roll, fanfold media

(Continuous label media, die-cut media, continuous tag media, and continuous ticket

media)

|

| Roll media orientation |

Outer surface |

| Recommended media |

Thermal-transfer: Label media (Lintec LR1111)

Direct-thermal media: Label media (Ricoh 150LA-1),

Tag media (Ricoh 130LHB)

|

| Max. media width |

118.0 mm / 4.65 inch |

| Min. media width |

25.4 mm / 1.00 inch |

| Min. label width |

21.5 mm / 0.85 inch |

| Min. media pitch*1 |

8.89 mm / 0.35 inch*2 |

| Max. media thickness |

0.19 mm / 0.0075 inch |

|

|

| Max. media length |

CL-E321 |

(Datamax) 2539.7mm/99.99inch

(Zebra) 2540.0mm/100.00inch

|

| CL-E331 |

1,270.0 mm / 50.00 inch |

| Min. media length*1 |

6.35 mm / 0.25 inch*2 |

| Min. media thickness |

0.0635 mm / 0.0025 inch |

| Loaded roll diameter |

Max. external diameter: 127 mm / 5 inch |

| Media core: 25.4 or 38.1 mm / 1 or 1.5 inch |

*1 To use media with a pitch of less than 1 inch, enable the [Small Media Adjustment] setting.

*2 For models with a cutter, the cutter operation will not be performed if the media

length is less than 25.4 mm (1 inch).

Ribbon

| Item |

Description |

| Ribbon wind direction |

Outer winding (ink surface facing outward) |

| Recommended ribbon |

B110A (Ricoh) |

| Max. ribbon width |

114.0 mm / 4.50 inch |

| Min. ribbon width |

35.0 mm / 1.38 inch |

| Max. ribbon length |

300.0 m / 984 feet |

| Max. roll diameter |

68.0 mm / 2.68 inch |

| Core inner diameter |

25.4 ±0.254 mm / 1.00 ±0.01 inch |

| Core outer diameter |

33.4 ±0.50 mm / 1.31 ±0.02 inch |

| Ribbon end tape length |

Max. 80 mm / 3.15 inch |

| Ribbon end detection |

Ink ribbon end detection by ribbon encoder sensor |

Barcodes

| Item |

Description |

| Datamax® emulation |

One-dimensional |

・Code 3 of 9 ・UPC-A ・UPC-E ・EAN-13 (JAN-13) ・EAN-8 (JAN-8) ・Interleaved 2 of 5 ・Code

128 ・HIBC (Code 3 of 9 using Modulus 43) ・Codabar (NW-7) ・Int 2 of 5 (Interleaved

2 of 5 using Modulus 10) ・Plessey ・Case Code ・UPC2DIG Add ・UPC5DIG Add ・Code 93 ・Telepen・ZIP ・UCC/EAN128 ・UCC/EAN128(for K-MART) ・UCC/EAN128 Random Weight ・FIM

|

| Two-dimensional |

・Maxi Code ・PDF-417 ・Data Matrix ・QR Code

・Aztec ・GS1 Databar Omnidirectional (RSS-14)

・GS1 Databar Truncated (RSS-14 Truncated)

・GS1 Databar Stacked (RSS-14 Stacked)

・GS1 Databar Stacked Omnidirectional

(RSS-14 Stacked Omnidirectional)

・GS1 Databar Limited (RSS Limited)

・GS1 Databar Expanded (RSS Expanded)

|

| Zebra® emulation |

One-dimensional |

・Code 11 ・Interleaved 2 of 5 ・Code 39 ・EAN-8 ・UPC-E

・Code93 ・Code128 ・EAN-13

・Industrial 2 of 5 ・Standard 2 of 5 ・ANSI CODABAR ・LOGMARS ・MSI ・Plessey ・UPC/EAN

Extensions ・UPC-A ・POSTNET ・Planet

|

| Two-dimensional |

・Code49 ・PDF-417 ・CODA BLOCK ・Maxi Code ・Micro PDF-417 ・Data Matrix ・QR Code ・TLC39

・Aztec

・GS1 Databar Omnidirectional (RSS-14)

・GS1 Databar Truncated (RSS-14 Truncated)

・GS1 Databar Stacked (RSS-14 Stacked)

・GS1 Databar Stacked Omnidirectional

(RSS-14 Stacked Omnidirectional)

・GS1 Databar Limited (RSS Limited)

・GS1 Databar Expanded (RSS Expanded)

|

| Eltron® emulation |

One-dimensional |

・Code39 ・Code93 ・Code128 ・Codabar ・EAN-8 ・EAN-13

・German Postal Code・Interleaved2of5 ・POSTNET ・Planet

・Japanese Postnet ・UCC/EAN-128 ・UPC-A ・UPC-E

・UPC-Interleaved2of5 ・Plessey(MSI-1) ・MSI-3

|

| Two-dimensional |

・Aztec ・Data Matrix ・MaxiCode ・PDF-417 ・QR Code

・GS1 Databar Omnidirectional (RSS-14)

・GS1 Databar Limited (RSS Limited)

・GS1 Databar Stacked (RSS-14 Stacked)

・GS1 Databar Truncated (RSS-14 Truncated)

|

Fonts

| Item |

Description |

| Datamax® emulation |

- 1.7 types of fixed-pitch fonts

- 2.OCR fonts

- OCR-A*3 and OCR-B*3

- 3.Proportional fonts

- CG Triumvirate smooth font

- CG Triumvirate bold smooth font

- CL-E321: 6, 8, 10, 12, 14, 18, 24, 30, 36, and 48 points

- CL-E331: 4, 5, 6, 8, 10, 12, 14, 18, 24, 30, 36, and 48 points

- Character sets: Compliant with code page 850

- 4.TrueType™ rasterizer

- 5.Kanji fonts (Gothic)

JIS 1st level Kanji, JIS 2nd level Kanji, Special symbol, Extended Kanji

16 dot, 24 dot, 32 dot, 48 dot

|

| Zebra® emulation |

- 1.5 types of fixed-pitch fonts

- 2.OCR fonts

- OCR-A*3 and OCR-B*3

- 3.Proportional fonts

- CG Triumvirate Condensed Bold

- 4.TrueType™ rasterizer

- 5.Kanji font (Gothic)

- JIS 1st level Kanji, JIS 2nd level Kanji, Special symbol, Extended Kanji

- 24 dot

|

| Eltron® emulation |

- 1.5 types of fixed-pitch fonts

- 2.2 types of fixed-pitch fonts

- 3.Kanji font (Gothic)

- JIS 1st level Kanji, JIS 2nd level Kanji, Special symbol, Extended Kanji

- 24 dot

|

*3 Depending on the reader, OCR font recognition may be poor.

Symbol Sets*4

| Item |

Description |

Single-Byte sets

(Datamax® , Zebra® Emulation)

|

・PC866U Ukrainian*5 ・PC Cyrillic ・ISO 60 Danish/Norwegian ・Desk Top ・ISO 8859/1 Latin

1 ・ISO 8859/2 Latin 2 ・ISO 8859/9 Latin 5 ・ISO 8859/10 Latin 6

・ISO 8859/7 Latin/Greek

・ISO 8859/15 Latin 9 ・ISO 8859/5 Latin/Cyrillic ・ISO 69: French ・ISO 21: German ・ISO

15: Italian ・Legal, Math-8 ・Macintosh

・Math ・PC-858 Multilingual ・Microsoft Publishing

・PC-8 ・PC-437 USA ・PC-8 D/N ・PC-437N ・PC-852 Latin/Greek ・PC-862 Latin/Hebrew ・Pi

Font ・PC-850 Multilingual ・PC-864 ・Latin/Arabic ・PC-8 TK ・PC-437T ・PC-1004 ・PC-775

Baltic・Non-UGL ・Generic Pi Font ・Roman-8 ・Roman-9 ・ISO 17: Spanish

・ISO 11: Swedish

・Symbol ・PS Text ・ISO 4: United Kingdom ・ISO 6: ASCII ・Ventura International ・Ventura

Math ・Ventura US・Windows 3.1 Latin 1

・Wingdings ・Windows 3.1 Latin 2 ・Windows 3.1

Baltic (Latv, Lith) ・Windows 3.0 Latin 1 ・Windows Latin/Cyrillic ・Windows 3.1 Latin

5

|

Double-byte sets

(Datamax® Emulation)

|

・EUC ・JIS ・Shift JIS ・Unicode ・KS Code ・GB Code |

*4 Use it when drawing a TrueType font. Eltron® Emulation does not support a TrueType

font.

*5 “PC866U Ukraina” is supported only in Datamax® emulation.

Control Languages

Supports the Datamax® language, Zebra® language and Eltron® language

Digital Processing Components

| Item |

Description |

| CPU |

32-bit RISC CPU (max. operation frequency of 216 MHz) |

| ROM |

16 MBytes of flash ROM (user area: 4 MBytes) |

| RAM |

32 MBytes of SDRAM (user area: 4 MBytes) |

Media detection sensors

| Item |

Description |

| Transmissive sensor |

Detects label gaps, tag notches, and out of media state |

| Reflective sensor |

Detects black lines on back of media and out of media state |

| Ribbon encoder sensor |

Ink ribbon end detection |

Communication interfaces

| Item |

Description |

| USB |

Full-speed USB 2.0 (12 Mbps), Type B connector |

| Ethernet |

100BASE-TX / 10BASE-T, RJ45 connector |

| Serial |

RS232C, 9-pin D-SUB female connector

Baud rates: 2400, 4800, 9600, 19200, 38400, 57600, and 115200 bps |

Indicators and switches

| Item |

Description |

| LED |

Power on (green), status/errors/alarms (green, red, and amber) |

| Buzzer |

Alarms, warnings, and other indications |

| Operation keys |

1 (Performs feed and other operations) |

| Head-up detection switch |

Detects head-up states |

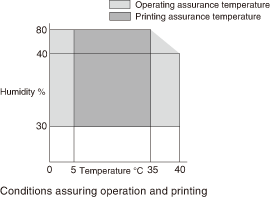

| Ethernet panel button |